Preparation method for composite positive electrode material used for solid-state lithium ion battery

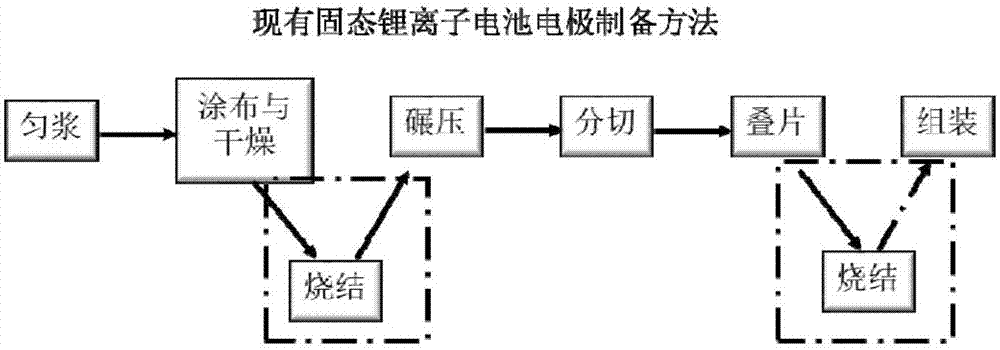

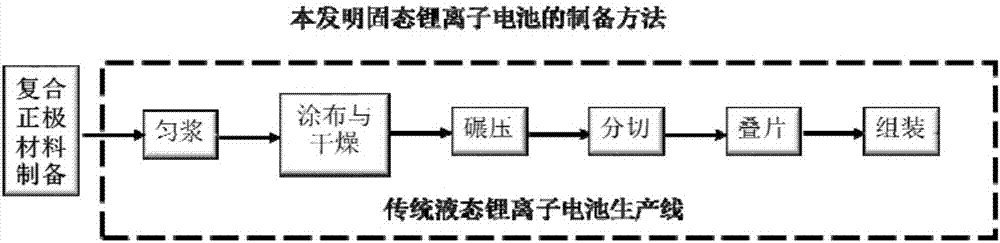

A composite positive electrode material and lithium-ion battery technology, applied in battery electrodes, electrolyte storage battery manufacturing, secondary batteries, etc., can solve the problems of high cost, damage to the continuity of the electrode production line of liquid lithium-ion batteries, etc., and achieve high conductivity and high rate Good discharge performance and reduced equipment modification costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0050] According to one embodiment, a positive electrode for a solid-state lithium-ion battery is prepared as follows:

[0051] a) uniformly mixing the solid electrolyte or its precursor with the positive electrode active material or its precursor to obtain a mixture powder;

[0052] b) sintering the mixture powder at high temperature to obtain a composite positive electrode material comprising a solid electrolyte and a positive electrode active material in powder form; and

[0053] c) preparing the obtained composite positive electrode material into a positive electrode slurry, coating the obtained positive electrode slurry on the positive electrode substrate, drying, rolling, and cutting to obtain the positive electrode.

[0054] The cathode slurry is prepared by dissolving or dispersing composite cathode materials, conductive additives, and binders in a solvent.

[0055] In one embodiment, the positive electrode slurry is prepared as follows: the composite positive electro...

Embodiment 1

[0108] Selection of NASICON-type Li-ion conductors as solid electrolytes, LiCoO 2 As the positive electrode material, the solid electrolyte precursor powder (Li 2 CO 3 :Al(OH) 3 :GeO 2 :NH 4 h 2 PO 4 According to Li 1.52 Al 0.5 Ge 1.5 P 3 o 12.01 stoichiometric ratio) and LiCoO 2 powder. The mixed powder was ball milled with a planetary ball mill at a speed of 400r / min for 24 hours. Transfer the mixture powder after ball milling to Al 2 o 3 In the crucible, put the crucible into a muffle furnace, raise the temperature to 750°C at 5°C / min, and keep it at 750°C for 12h to obtain a composite cathode material powder with a particle size of 100nm.

[0109] According to composite cathode material: Super P:KS-6:PVDF=88:4:2:6 mass ratio composite cathode material, Super P, KS-6 and PVDF are mixed to obtain 10 grams of mixtures, and the mixture is dispersed in 5 grams of NMP , fully stirred evenly with a vacuum planetary mixer to obtain positive electrode slurry. The p...

Embodiment 2

[0113] Selection of NASICON-type Li-ion conductors as solid electrolytes, LiCoO 2 As the positive electrode material, the solid electrolyte Li 1.52 Al 0.5 Ge 1.5 P 3 o 12.01 and LiCoO 2 powder. The mixed powder was ball milled with a planetary ball mill at a speed of 400r / min for 24 hours. Transfer the mixed powder after ball milling to Al 2 o 3 In the crucible, put the crucible into a muffle furnace, raise the temperature to 750°C at 5°C / min, and keep it at 750°C for 12 hours to obtain a composite positive electrode material powder with a particle size of 90nm.

[0114] According to composite cathode material: Super P:KS-6:PVDF=88:4:2:6 mass ratio composite cathode material, Super P, KS-6 and PVDF are mixed to obtain 10 grams of mixtures, and the mixture is dispersed in 5 grams of NMP , fully stirred evenly with a vacuum planetary mixer to obtain positive electrode slurry. The positive electrode slurry was coated on an aluminum foil with a thickness of 18 μm, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com