Composite material with layered three-dimensional ordered porous structure as well as preparation method and application of composite material

A three-dimensional ordered, porous structure technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., to achieve the effect of solving poor mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A method for preparing a layered three-dimensional ordered porous structure composite material, comprising the steps of:

[0042] (1) Weigh 120mg of ascorbic acid in a 30ml glass bottle, add 12ml of deionized water, stir and dissolve, add 80mg of copper nanowires and 8ml of graphene oxide aqueous solution (5mg / ml), ultrasonic 30min (copper nanowires and graphene oxide Mass ratio is 2:1), obtains mixed solution;

[0043] (2) heating the mixed solution obtained in step (1) to 40° C., and keeping it for 3 hours, and obtaining a composite film by vacuum filtration;

[0044] (3) The composite film described in step (2) was vertically immersed in liquid nitrogen for 1 min, then taken out and placed in a refrigerator, and dried to obtain a copper nanowire-graphene layered three-dimensional ordered porous structure composite material.

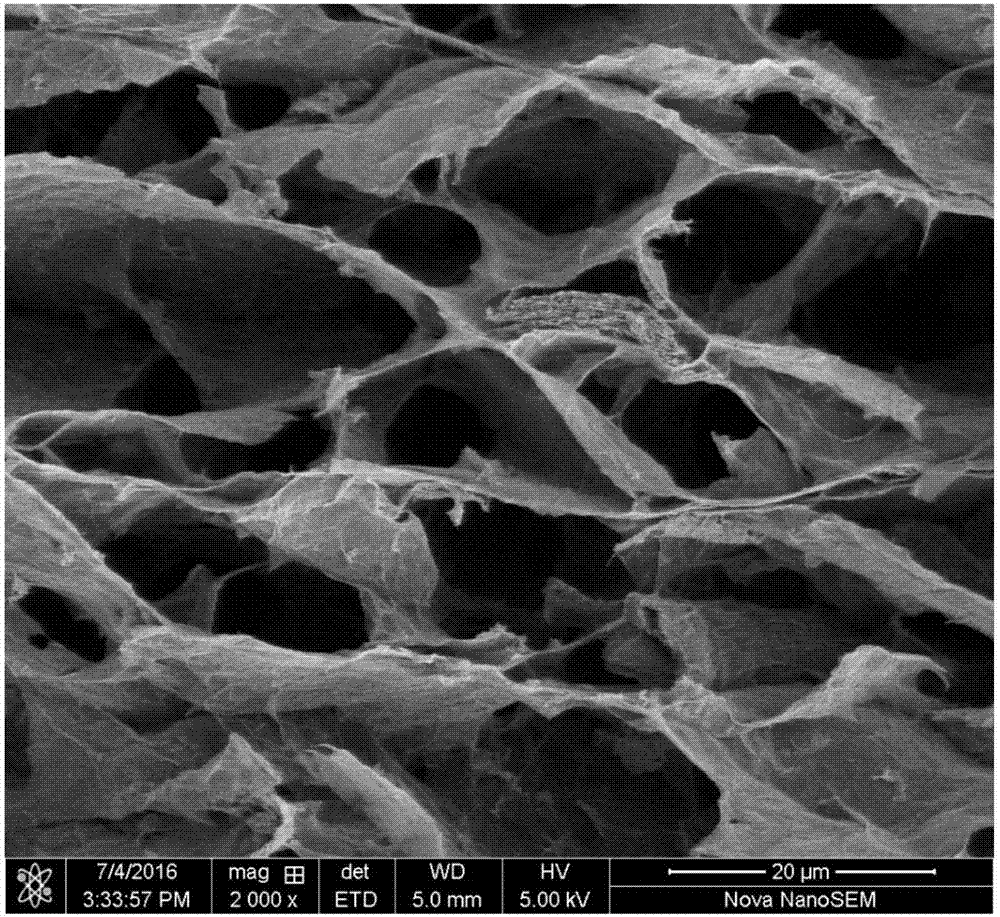

[0045] figure 1 The SEM figure of the copper nanowire-graphene layered three-dimensional ordered porous structure composite material prepared...

Embodiment 2

[0048] The preparation method of the layered three-dimensional ordered porous structure composite material in this example differs from that in Example 1 only in that: Step (2) is at 40° C. and the heating time is 4 hours.

[0049] Other steps of the preparation method of the layered three-dimensional ordered porous structure composite material in this embodiment are the same as in Embodiment 1.

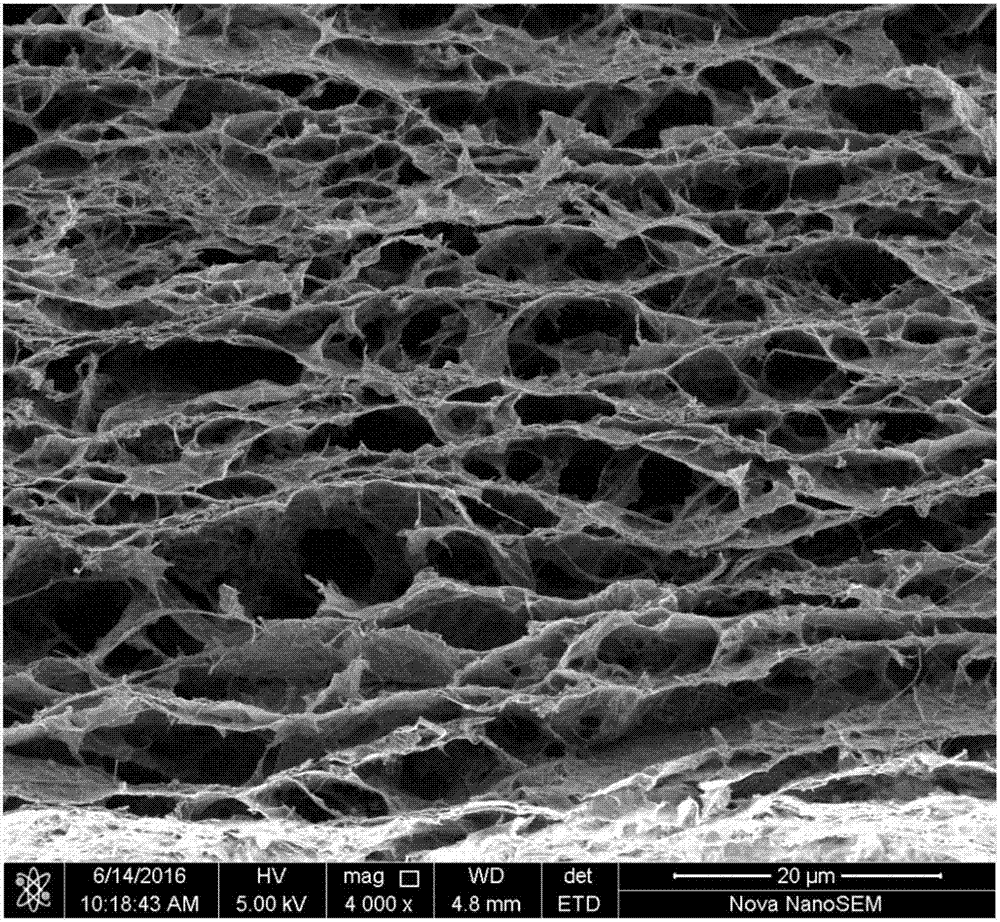

[0050] image 3 The SEM figure of the copper nanowire-graphene layered three-dimensional ordered porous structure composite material prepared in this embodiment is shown, as can be seen from the figure, the copper nanowire-graphene composite structure has an obvious layered structure, And it has an ordered porous structure, and copper nanowires are distributed between graphene sheets.

Embodiment 3

[0052] The preparation method of the layered three-dimensional ordered porous structure composite material in this example differs from that in Example 1 only in that the heating time at 40° C. is 5 hours.

[0053] Other steps of the preparation method of the layered three-dimensional ordered porous structure composite material in this embodiment are the same as in Embodiment 1.

[0054] Figure 4 The SEM figure of the copper nanowire-graphene layered three-dimensional ordered porous structure composite material prepared in this embodiment is shown, as can be seen from the figure, the copper nanowire-graphene composite structure has an obvious layered structure, And it has an ordered porous structure, and copper nanowires are distributed between graphene sheets.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap