Preparation method of fused silica ceramic revolving body

A technology of fused silica and fused silica powder, which is applied in the field of preparation of fused silica ceramic revolving bodies, can solve the problems of long molding time, easy shadowing of products, and high porosity, and achieves simple molding methods and solves the grouting molding process cycle Long-lasting, low-alcohol effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

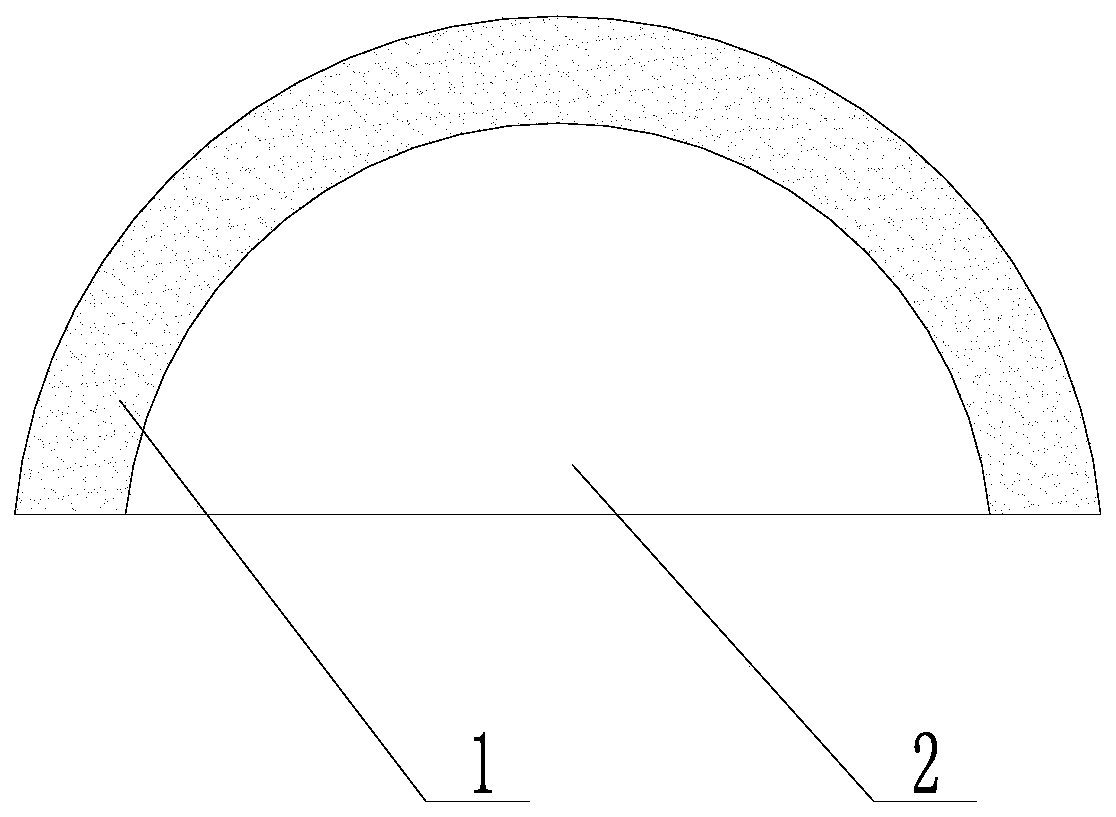

Image

Examples

Embodiment 1

[0044] The preparation method of the fused silica ceramic revolving body comprises the following steps:

[0045] (1) Preparation of alcohol-based quartz slurry

[0046] Mix the fused silica powder with a median diameter of 30 μm and the fused silica powder with a median diameter of 10 μm, wherein the fused silica powder with a median diameter of 30 μm accounts for 30 wt%, then add alcohol and thermosetting resin to stir and mix for 4 hours, and let it stand for stale 36h, stirred again for 6h to obtain an alcohol-based quartz slurry, wherein the alcohol in the slurry accounts for 17.5wt%, and the phenolic resin accounts for 0.5wt%;

[0047] (2) Preparation of green body

[0048] The green body is prepared by high-pressure grouting method, and it is made after stripping;

[0049] The high-pressure grouting process is divided into two processes: low-pressure grouting and pressure-holding and alcohol removal in stages: first, grouting is carried out at 0.5MPa until the mold is ...

Embodiment 2

[0055] The preparation method of the fused silica ceramic revolving body comprises the following steps:

[0056] (1) Preparation of alcohol-based quartz slurry

[0057] Mix the fused silica powder with a median diameter of 20 μm and the fused silica powder with a median diameter of 5 μm, wherein the fused silica powder with a particle diameter of 15 μm accounts for 40 wt%, then add alcohol and thermosetting resin to stir and mix for 5 hours, and let it stand for 48 hours , stirred again for 8h to obtain an alcohol-based quartz slurry, wherein the alcohol in the slurry accounts for 16.5wt%, and the phenolic resin accounts for 5wt%;

[0058] (2) Preparation of green body

[0059] The green body is prepared by high-pressure grouting method, and it is made after stripping;

[0060]The high-pressure grouting process is divided into two processes: low-pressure grouting and pressure-holding and alcohol removal in stages: first, grouting is performed at 0.2MPa until the mold is full...

Embodiment 3

[0066] The preparation method of the fused silica ceramic revolving body comprises the following steps:

[0067] (1) Preparation of alcohol-based quartz slurry

[0068] Mix fused silica powder with a median diameter of 50 μm and fused silica powder with a median diameter of 15 μm, wherein the fused silica powder with a particle diameter of 50 μm accounts for 10 wt%, then add alcohol and thermosetting resin to stir and mix for 3 hours, and let it stand for 24 hours , stirred again for 4h to obtain an alcohol-based quartz slurry, wherein the alcohol in the slurry accounts for 20wt%, and the phenolic resin accounts for 0.1wt%;

[0069] (2) Preparation of green body

[0070] The green body is prepared by high-pressure grouting method, and it is made after stripping;

[0071] The high-pressure grouting process is divided into two processes: low-pressure grouting and pressure-holding and alcohol removal in stages: first, grouting is performed at 0.1MPa until the mold is full of gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com