Synthetic method of trisubstituted oxaphosphinane compound or trisubstituted dioxaphosphinane compound

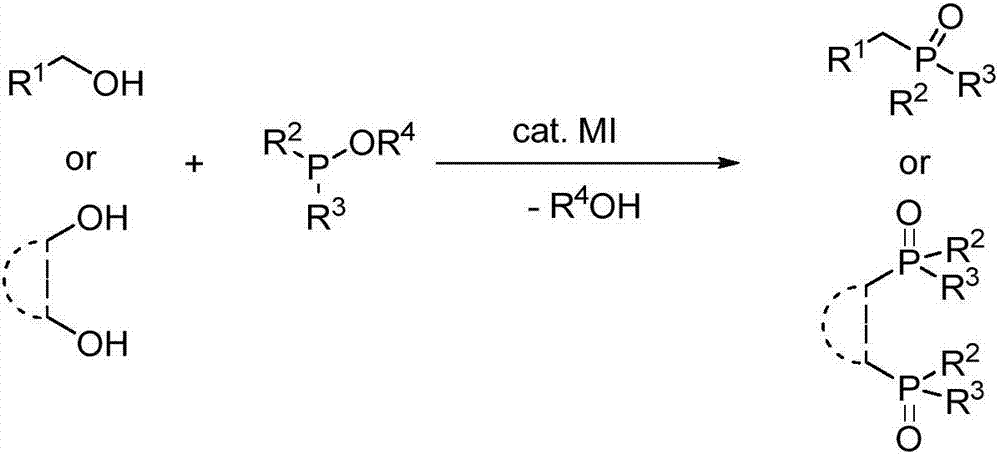

A synthesis method and compound technology, which is applied in the field of synthesis of trisubstituted phosphine oxides and dioxide phosphine, can solve problems such as poor stability, low atom economy, and low efficiency, and meet low requirements for reaction conditions, wide application prospects, and applicable wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

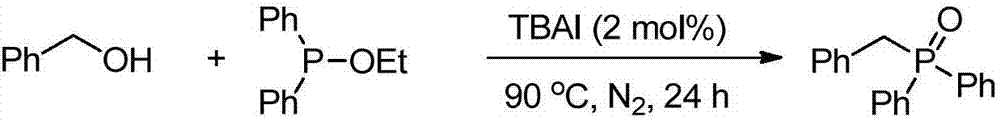

[0024] Preparation of Benzyldiphenylphosphine Oxide from Diphenylethoxyphosphine and Benzyl Alcohol

[0025]

[0026] In a 20mL tubular reactor, diphenylethoxyphosphine (115.0mg, 0.50mmol), benzyl alcohol (108.0mg, 1.0mmol, 2.0equiv.) and tetrabutylammonium iodide (3.7mg, 0.01mmol, 2mol%), vacuumed under nitrogen protection, and then heated to 90° C. for 24 h under solvent-free conditions. After the complete reaction was monitored by TLC, the product was separated and purified by column chromatography, and the separation yield was 89%. 1 H NMR (500MHz, CDCl 3 )δ7.84–7.60(m,4H),7.60–7.36(m,6H),7.27–7.13(m,3H),7.18–6.92(m,2H),3.66(d,J=14.0Hz,2H) . 13 C NMR (125MHz, CDCl 3 )δ132.24(d, J=98.4Hz), 131.79(d, J=2.7Hz), 131.19(d, J=9.1Hz), 130.16(d, J=5.2Hz), 128.49(d, J=11.7 Hz), 128.37(d, J=2.5Hz), 126.79(d, J=2.9Hz), 38.15(d, J=66.3Hz). 31 P NMR (202MHz, CDCl 3 )δ29.45(s).

Embodiment 2

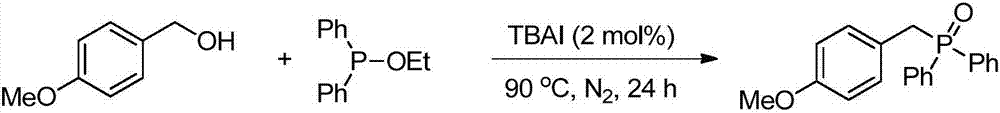

[0028] Preparation of 4-(methoxy)benzyldiphenylphosphine oxide from diphenylethoxyphosphine and 4-methoxybenzyl alcohol

[0029]

[0030] Add diphenylethoxyphosphine (115.0mg, 0.50mmol), 4-methoxybenzyl alcohol (138.0mg, 1.0mmol, 2.0equiv.) and tetrabutylammonium iodide (3.7 mg, 0.01mmol, 2mol%), evacuated under nitrogen protection, and then heated to 90°C for 24h under solvent-free conditions. After the complete reaction was monitored by TLC, the product was separated and purified by column chromatography, and the separation yield was 91%. 1 H NMR (500MHz, CDCl 3 )δ7.87–7.61(m,4H),7.60–7.36(m,6H),7.02(dd,J=8.5,2.0Hz,2H),6.73(d,J=8.5Hz,2H),3.74(s ,1H),3.59(d,J=13.5Hz,1H). 13 C NMR (125MHz, CDCl 3 )δ158.54(d, J=2.9Hz), 132.42(d, J=98.0Hz), 131.76(d, J=2.7Hz), 131.19(d, J=9.3Hz), 131.13(d, J=5.8 Hz), 128.49(d, J=11.6Hz), 122.91(d, J=8.1Hz), 113.91(d, J=2.5Hz), 55.20, 37.12(d, J=67.5Hz). 31 P NMR (202MHz, CDCl 3 )δ29.44(s).

Embodiment 3

[0032] Preparation of 4-(chloro)benzyldiphenylphosphine oxide from diphenylethoxyphosphine and 4-chlorobenzyl alcohol

[0033]

[0034] In a 20mL tubular reactor, diphenylethoxyphosphine (115.0mg, 0.50mmol), 4-chlorobenzyl alcohol (142.0mg, 1.0mmol, 2.0equiv.) and tetrabutylammonium iodide (3.7mg, 0.01mmol, 2mol%), vacuumed under nitrogen protection, and then heated to 90°C for 24h under solvent-free conditions. After the complete reaction was monitored by TLC, the product was separated and purified by column chromatography, and the separation yield was 72%. 1 H NMR (500MHz, CDCl 3 )δ7.70(d, J=7.5Hz, 2H), 7.67(d, J=8.0Hz, 2H), 7.55–7.42(m, 6H), 7.15(d, J=8.5Hz, 2H), 7.04( d,J=8.0Hz,2H),3.61(d,J=13.5Hz,2H). 13 C NMR (125MHz, CDCl 3 )δ132.86(d, J=3.6Hz), 132.02(d, J=98.9Hz), 131.96(d, J=2.7Hz), 131.38(d, J=5.3Hz), 131.11(d, J=9.2 Hz), 129.72(d, J=8.1Hz), 128.60(d, J=11.9Hz), 128.54(d, J=3.6Hz), 37.48(d, J=66.2Hz). 31 P NMR (202MHz, CDCl 3 )δ29.07(s).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com