Method for extracting SOD (Superoxide Dismutase) refined enzyme from SOD enriched plants (triticale and rice oil bran powder) after biological fermentation

A technology of biological fermentation and rice oil bran, applied in the biological field, can solve the problems of uncontrollable dosage, unquantifiable, low sod content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] 1. Choose oily pine needles (Pinus tabuliformis Carrire) 30 kg and cut into inch sections

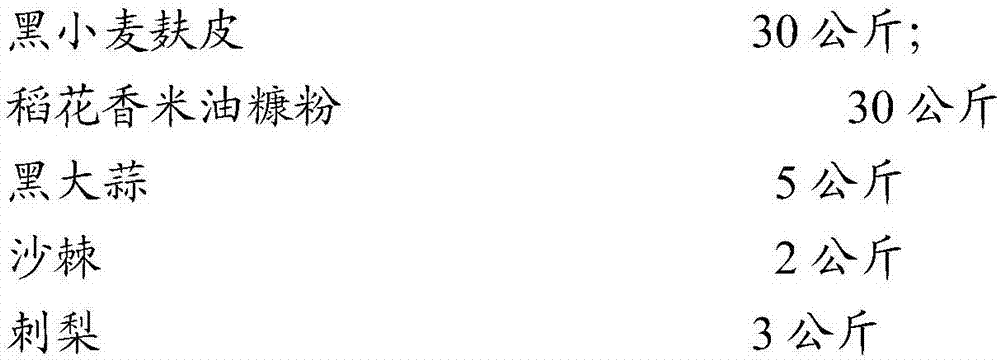

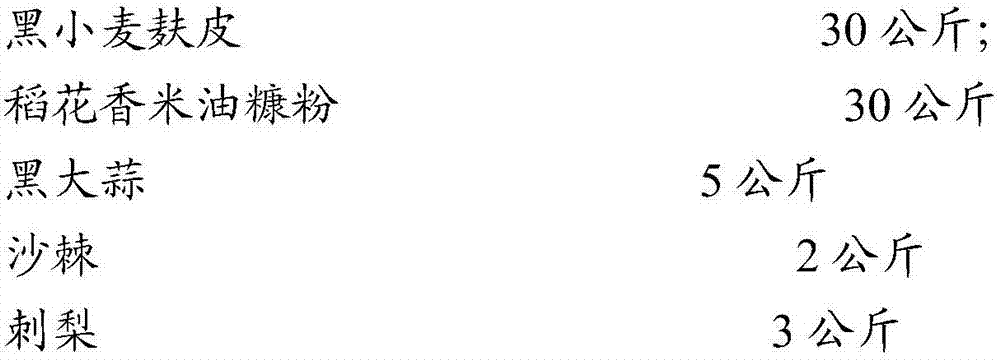

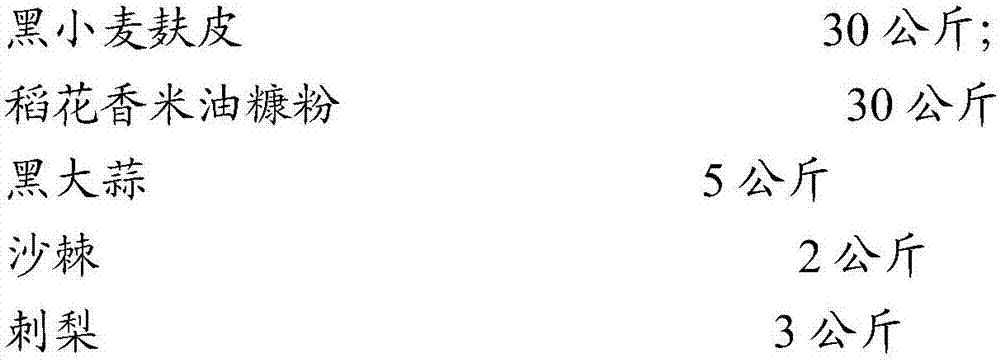

[0061]

[0062] Mix evenly according to the above ratio, a total of 100 kilograms.

[0063] 2. Add 300 kg of water and use a stone mill for wet grinding;

[0064] 3. The collected oar liquid first passes through a 100-mesh filter, a 500-mesh filter, and an 800-mesh filter to collect the filtrate.

[0065] 4. Use molecular sieves (American GE (Sweden amersham) 17-0612-10SEPHACRYL S-100HR, 150ML (gel filtration filler Sephacryl), condition pH7.8, 50mmol / LPBS for elution and control the flow rate to 42mL / h) for sod molecules After screening, sod crude enzyme is obtained.

[0066] 5. Heating at 10°C to 40°C, standing for 72 hours, and passing through the above-mentioned sod molecular sieves and conditions to obtain a new sod filtrate.

[0067] 6. Low-temperature (-18 to -198° C.) spray freeze-drying, and the collected dry powder is the new product sod essence, named Laobing Yiw...

Embodiment 2

[0071] Embodiment 2 (dry method)

[0072] 1. Choose oily pine needles (Pinus tabuliformis Carrire) 30 kg and cut into inch sections

[0073]

[0074] Mix evenly according to the above ratio, a total of 100 kilograms.

[0075] 2. Dry at 40-58 degrees, and then pulverize (1500 mesh) with low-temperature airflow ultrafine pulverization;

[0076] 3. The collected raw material powder. After adding 65% of water, ferment at 10-40 degrees for 3 days, add 300 kg of water to obtain liquid filtration

[0077] 4. Use molecular sieves for sod molecular sieves (American GE (Amersham, Sweden) 17-0612-10SEPHACRYL S-100HR, 150ML (gel filtration filler Sephacryl), conditions pH 7.8, 50mmol / LPBS for elution and control flow rate 42mL / h) After screening, sod crude enzyme is obtained.

[0078] 5. Heating at 10° C. to 40° C., standing for 72 hours, and passing through the sod molecular sieve and conditions described in Example 1 to obtain new sod filtrate.

[0079] 6. Low-temperature (-18 t...

Embodiment 3

[0080] Embodiment 3 (alcohol extraction method)

[0081] 1. Choose oily pine needles (Pinus tabuliformis Carrire) 30 kg and cut into inch sections

[0082]

[0083] Mix evenly according to the above ratio, totaling 100 kilograms.

[0084] 2. Dry at 40-58 degrees, and then pulverize (500 mesh) with low-temperature airflow ultrafine pulverization;

[0085] 3. The collected raw material powder. Add 300 kilograms of 52-degree edible liquor and soak for 3 days at 10-40 degrees, stir and filter to obtain a supernatant, which is separated with a high-speed centrifuge.

[0086] 4. Use molecular sieves for sod molecular sieves (American GE (Amersham, Sweden) 17-0612-10SEPHACRYL S-100HR, 150ML (gel filtration filler Sephacryl), conditions pH 7.8, 50mmol / LPBS for elution and control flow rate 42mL / h) After screening, sod crude enzyme is obtained.

[0087] 5. Heating at 10°C-40°C, standing for 72 hours, and passing through the above-mentioned sod molecular sieve and conditions to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com