High-polymer adsorbing material for separating and purifying vitamin B12 from fermentation liquid

A technology for separation, purification and adsorption materials, which is applied in the direction of sugar derivatives, sugar derivatives, organic chemistry, etc., to avoid the problem of toxic monomer residues, improve the safety of use, and achieve the effect of efficient desorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

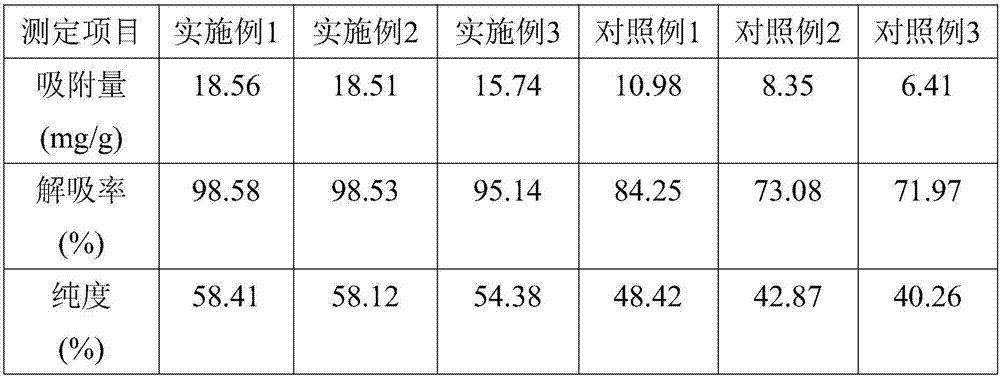

Examples

Embodiment 1

[0028] (1) Preparation of macroporous adsorption resin: add 45 parts of hydrogenated abietyl alcohol methacrylate, 30 parts of pentaerythritol triacrylate, 15 parts of dimethylaminoethyl acrylate, 40 parts of nanoporogen and 0.5 parts of initiator, mixed thoroughly, ultrasonically treated at ultrasonic frequency 40kHz, output power 200W for 15min, then microwaved at microwave frequency 2450MHz, output power 700W for 10min, and left at 0-5°C for 30min, after mixing evenly Continue microwave treatment for 10 minutes, then let stand at -5-0°C for 15 minutes, mix well and then microwave again for 10 minutes, cool down the mixture at a cooling rate of 5°C / min to 40-45°C for 1 hour, then mix Liquid-solid-liquid separation, the obtained solid phase was washed three times with warm water at 40-45°C to obtain white balls, and finally the white balls were vacuum-dried at 60-65°C to obtain macroporous adsorption resin;

[0029] (2) Pretreatment of macroporous adsorbent resin: add 2 parts...

Embodiment 2

[0034] (1) Preparation of macroporous adsorbent resin: add 50 parts of hydrogenated abietyl alcohol methacrylate, 40 parts of pentaerythritol triacrylate, 10 parts of dimethylaminoethyl acrylate, 50 parts of nanoporogen and 0.5 parts of initiator, mixed thoroughly, ultrasonically treated at ultrasonic frequency 40kHz, output power 200W for 15min, then microwaved at microwave frequency 2450MHz, output power 700W for 10min, and left at 0-5°C for 30min, after mixing evenly Continue microwave treatment for 10 minutes, then let stand at -5-0°C for 15 minutes, mix well and then microwave again for 10 minutes, cool down the mixture at a cooling rate of 5°C / min to 40-45°C for 1 hour, then mix Liquid-solid-liquid separation, the obtained solid phase was washed three times with warm water at 40-45°C to obtain white balls, and finally the white balls were vacuum-dried at 60-65°C to obtain macroporous adsorption resin;

[0035] (2) Pretreatment of macroporous adsorbent resin: add 2 parts ...

Embodiment 3

[0040] (1) Preparation of macroporous adsorbent resin: add 50 parts of hydrogenated abietyl alcohol methacrylate, 40 parts of pentaerythritol triacrylate, 10 parts of dimethylaminoethyl acrylate, 50 parts of nanoporogen and 0.5 parts of initiator, mixed thoroughly, ultrasonically treated at ultrasonic frequency 40kHz, output power 200W for 15min, then microwaved at microwave frequency 2450MHz, output power 700W for 10min, and left at 0-5°C for 30min, after mixing evenly Continue microwave treatment for 10 minutes, then let stand at -5-0°C for 15 minutes, mix well and then microwave again for 10 minutes, cool down the mixture at a cooling rate of 5°C / min to 40-45°C for 1 hour, then mix Liquid-solid-liquid separation, the obtained solid phase was washed three times with warm water at 40-45°C to obtain white balls, and finally the white balls were vacuum-dried at 60-65°C to obtain macroporous adsorption resin;

[0041] (2) Pretreatment of macroporous adsorbent resin: add 2 parts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com