Preparation method of compound electrochromic thin film

An electrochromic and thin-film technology, applied in the coating and other directions, can solve the problem that the electrochromic performance of a single conductive polymer cannot be satisfied, and achieve the effect of improving electrochromic performance, high sensitivity and expanding application fields.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

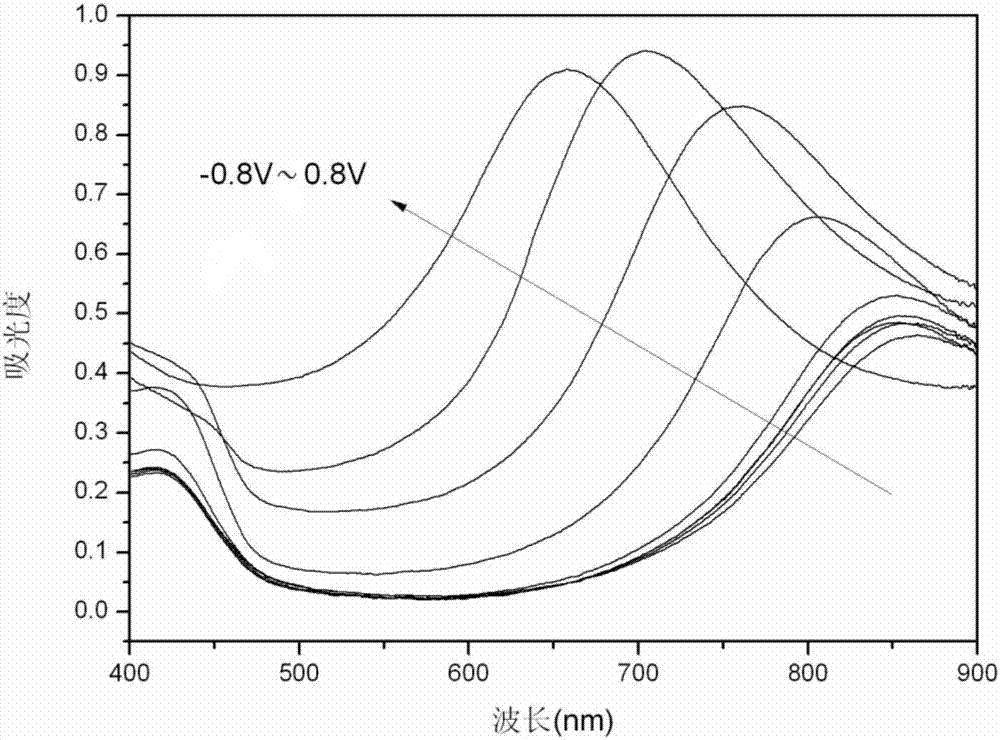

[0027] The preparation method of the conductive polyaniline / sodium diphenylamine sulfonate composite electrochromic film of this embodiment is:

[0028] Step 1. Preparation of polymerization reaction solution: the polymerization reaction solution is prepared by adding water to the monomer, doped acid and redox indicator. The concentration of the monomer in the polymerization reaction solution is 0.5 mol / L, and the concentration of the doped acid is 0.5 mol / L. mol / L, the concentration of the redox indicator is 0.005mol / L; the monomer is aniline; the doping acid is polystyrene sulfonic acid; the redox indicator is sodium diphenylamine sulfonate;

[0029] Step 2, in-situ chemical oxidation polymerization reaction: put the polymerization reaction solution described in step 1 in a cold water bath, and when the temperature of the polymerization reaction solution drops to 0°C, add the initiator in 3 times with an interval of 15 minutes each time In-situ chemical oxidation polymerizat...

Embodiment 2

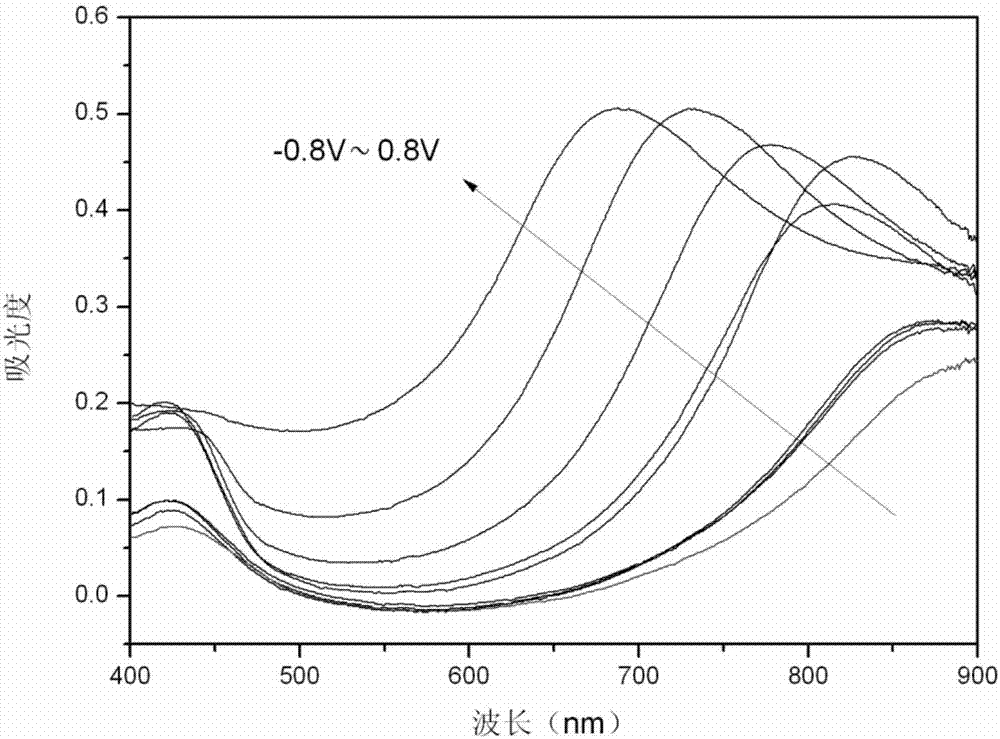

[0038] The preparation method of the conductive poly(3,4-ethylenedioxythiophene) / wool poppy red A composite electrochromic film of this embodiment is:

[0039] Step 1. Preparation of polymerization reaction solution: the polymerization reaction solution is prepared by adding water to the monomer, doping acid and redox indicator, the concentration of monomer in the polymerization reaction solution is 0.1mol / L, and the concentration of doping acid is 0.1mol / L mol / L, the concentration of the redox indicator is 0.001mol / L; the monomer is 3,4-ethylenedioxythiophene; the doping acid is polystyrene sulfonic acid; the redox indicator It is wool poppy red A;

[0040] Step 2. In-situ chemical oxidation polymerization reaction: put the polymerization reaction solution described in step 1 in a cold water bath, and when the temperature of the polymerization reaction solution drops to 0°C, add the initiator in 3 times with an interval of 15 minutes each time to initiate the polymerization r...

Embodiment 3

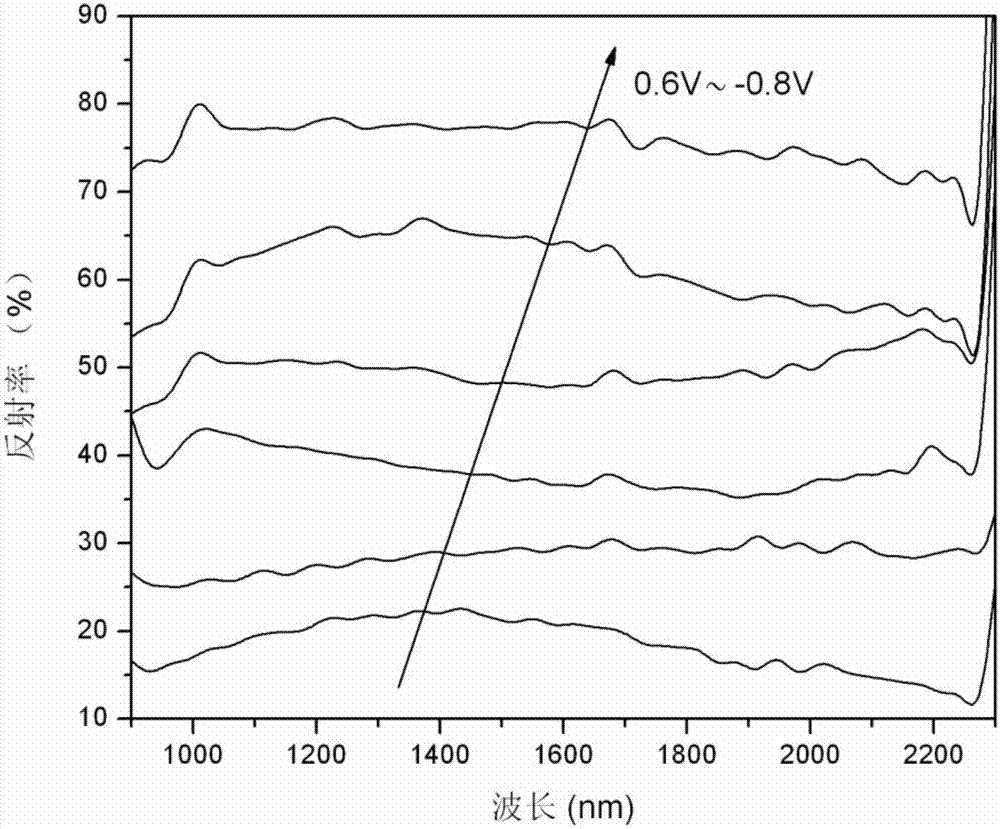

[0049] The preparation method of the conductive poly(3-pyrrole carboxylic acid) / o-anilinobenzoic acid composite electrochromic film of the present embodiment is:

[0050] Step 1. Prepare the polymerization reaction solution: the polymerization reaction solution is prepared by adding water to the monomer, the doping acid and the redox indicator. The concentration of the monomer in the polymerization reaction solution is 0.2mol / L, and the concentration of the doping acid is 0.2mol / L. mol / L, the concentration of the redox indicator is 0.001mol / L; the monomer is 3-pyrrole carboxylic acid; the doping acid is dodecylbenzenesulfonic acid; the redox indicator is o-aniline benzoic acid;

[0051] Step 2. In-situ chemical oxidation polymerization reaction: put the polymerization reaction solution described in step 1 in a cold water bath, and when the temperature of the polymerization reaction solution drops to 0°C, add the initiator in 3 times with an interval of 15 minutes each time to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com