Environment-friendly water-based demolding release composition

An environment-friendly, composition-based technology, applied in lubricating compositions, petroleum industry and other directions, can solve the problems of no good economic benefits, no energy saving and environmental protection, high labor costs, etc., achieve superior anti-stick mold function, improve production progress, The effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

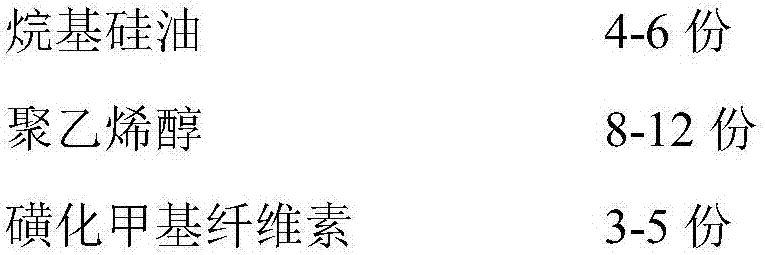

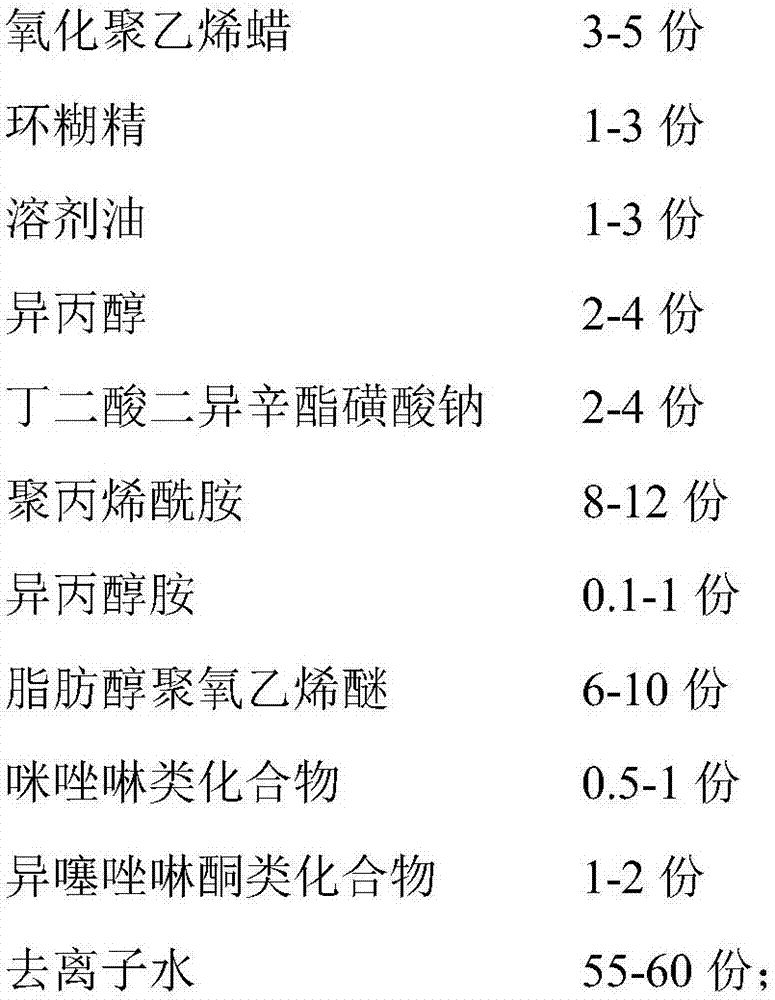

Examples

preparation example Construction

[0057] The second aspect of the present invention provides a method for preparing the environmentally-friendly water-based mold release composition as described above, which includes the following steps:

[0058] Add oxidized polyethylene wax, sodium diisooctyl succinate, polyacrylamide, and deionized water to the container, add alkyl silicone oil under stirring, stirring at 200-300rpm, stirring for 10-20min, heating To 35℃, add sulfonated methyl cellulose, cyclodextrin, imidazoline compounds, isothiazolinone compounds, keep for 10min, then heat to 50℃, adjust the stirring speed to 500-600rpm, and add fatty alcohol in turn Polyoxyethylene ether, mineral spirits, and polyvinyl alcohol are continuously stirred at 50°C for 10 minutes, then cooled to room temperature, and then isopropanol and isopropanolamine are added, and the mixture is evenly stirred to obtain.

[0059] The preparation method of the present invention can prevent the composition from agglomerating in water, facilitat...

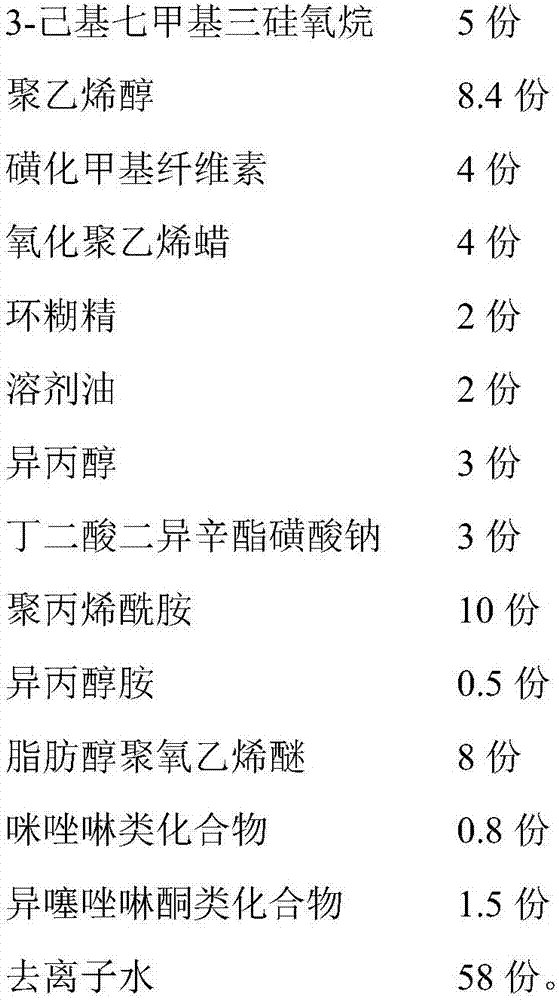

Embodiment

[0062] A1 3-hexyl heptamethyl trisiloxane

[0063] A2 heptamethyl trisiloxane

[0064] A3 Dimethicone

[0065] B1 Polyvinyl Alcohol PVA2488

[0066] B2 polyvinyl alcohol PVA2499

[0067] C sulfonated methyl cellulose

[0068] The preparation method of sulfonated methylcellulose is: stir 8.4g methylcellulose in 50mL 30wt% hydrogen peroxide aqueous solution for 1h, then use a rotary evaporator to evaporate the solvent, add 50mL tetrahydrofuran, and then cool with an ice bath , Keep the temperature below 5℃, add 1.2mL chlorosulfonic acid dropwise, and then continue to stir for 2h. After the reaction, the solvent is evaporated to dryness with a rotary evaporator, and then washed with acetone three times, using 10mL each time, and then vacuum dried for 5h. Got.

[0069] Dβ-cyclodextrin

[0070] E D40 solvent oil

[0071] F isopropanol

[0072] G Oxidized Polyethylene Wax

[0073] H Diisooctyl Sodium Succinate Sulfonate

[0074] I polyacrylamide

[0075] J isopropanolamine

[0076] K1 AEO-80

[0077]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com