A method for preparing scandium hydroxide from scandium-containing titanium waste acid solution

A technology of scandium hydroxide and waste acid solution, applied in the field of extraction, can solve the problems of long process flow and complicated operation steps for removing titanium by water, and achieve the effects of shortening the process flow, easy control of separation conditions and improving elution rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

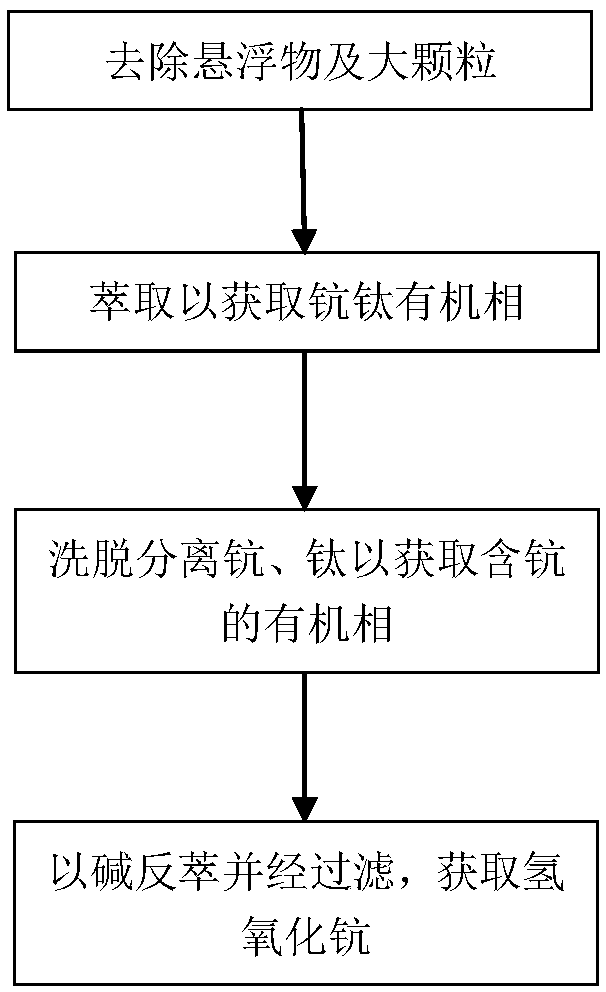

[0065] For further illustrating the method for preparing scandium hydroxide of the present invention, a kind of method for preparing scandium hydroxide by scandium-containing titanium waste acid solution, it comprises the following steps:

[0066] Step S1, removing suspended solids and large particles of impurities from the waste acid solution containing scandium and titanium to obtain clarified acid solution;

[0067] Step S2, extracting the clarified acid solution to obtain a scandium-titanium organic phase enriched in scandium and titanium, wherein the extraction agent used in the extraction is bis(2-ethylhexyl) phosphate dissolved in solvent oil. A mixture or a mixture of di(2-ethylhexyl) phosphate and tributyl phosphate dissolved in solvent oil, the volume fraction of the di(2-ethylhexyl) phosphate in the mixture is 5%-25% %, and / or, the volume fraction of the tributyl phosphate in the mixture is 2%-5%, and the ratio of the extracted organic phase to the aqueous phase is ...

Embodiment 1

[0075] A kind of method of preparing scandium hydroxide by scandium-containing titanium waste acid solution of the present embodiment, its specific operation steps are as follows:

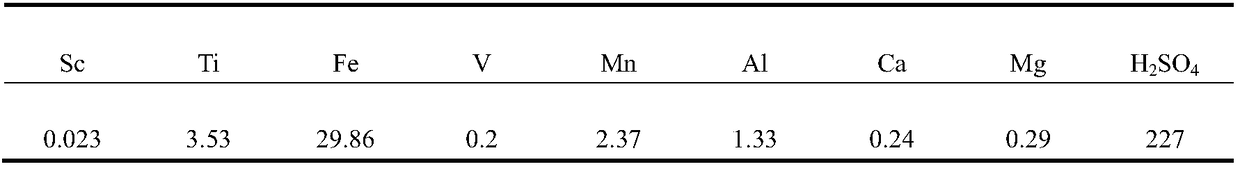

[0076] (1) Filtrating the waste acid solution containing scandium and titanium to obtain clarified acid solution. Among them, the components of scandium-containing titanium waste acid solution are shown in Table 1.

[0077] (2) Adding an extractant to the clarified acid solution, wherein the extractant is a mixture containing 10% of di(2-ethylhexyl) phosphate and 90% of kerosene. Take a separatory funnel for three-stage cascaded countercurrent extraction, the volume ratio of the organic phase to the aqueous phase is 1:21, and the single-stage extraction time is 15 minutes to obtain a scandium-titanium organic phase containing 270 mg / L scandium and 5.6 g / L titanium .

[0078](3) Add an eluent to the scandium-titanium organic phase containing scandium 270mg / L and titanium 5.6g / L, wherein the eluent...

Embodiment 2

[0082] (1) Filtrating the waste acid solution containing scandium and titanium to obtain clarified acid solution. Among them, the components of scandium-containing titanium waste acid solution are shown in Table 1.

[0083] (2) Adding an extractant to the clarified acid solution, wherein the extractant is a mixture containing 10% di(2-ethylhexyl) phosphate, 5% tributyl phosphate and 85% kerosene. A separatory funnel was used for three-stage cascaded countercurrent extraction, the ratio of the organic phase to the aqueous phase in the extraction system was 1:21, and the extraction time was 15 minutes to obtain a scandium-titanium organic compound containing 430 mg / L scandium and 6.05 g / L titanium. Mutually.

[0084] (3) Add an eluent to the scandium-titanium organic phase containing scandium 430mg / L and titanium 6.05g / L, wherein the eluent is Na 3 PO 4 and H 2 o 2 mixed solution of Na 3 PO 4 and H 2 o 2 The molar ratio with Ti is n Na3PO4 / n Ti = 1.5 / 1, n H2O2 / n T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com