Halogen-free, flame-retardant and ablation-resistant fiber material, and preparation method and application thereof

A technology of ablation-resistant fiber and polyimide fiber, which is applied in the manufacture of fire-resistant and flame-retardant filaments, fiber chemical characteristics, textiles and papermaking, etc. Meet the requirements of flame retardant filling, limited specific surface area, etc., and achieve good thermal insulation effect and air permeability, high fire protection safety, and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

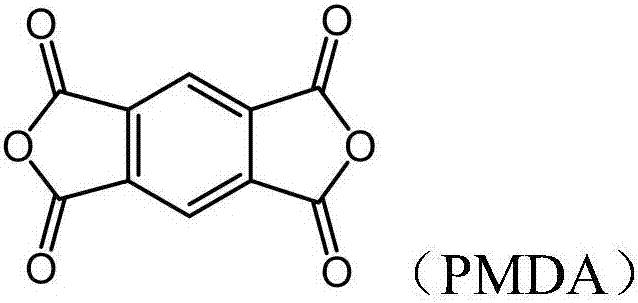

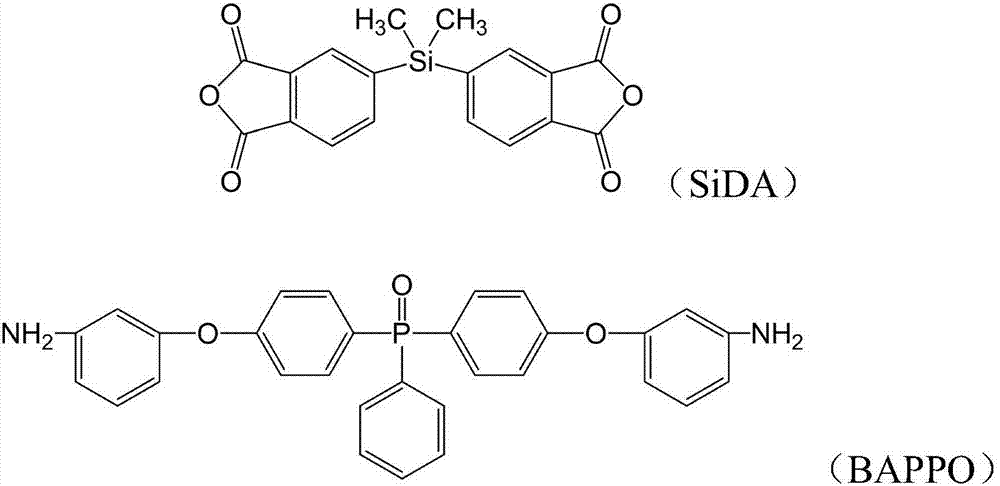

[0027] 1) PMDA, SiDA and BAPPO three monomers are prepared by polycondensation reaction according to the ratio of 80:20:100 to obtain polyimide fibers, the diameter of the fibers is 10 μm, and the linear density of the tow is 1100dtex;

[0028] 2) The polyimide fiber obtained in step 1) is mechanically cut to obtain short fibers with a length of 3 cm, and then the short fibers are dispersed in water by a disintegrator to obtain a slurry suspension with a concentration of 1 wt %;

[0029] 3) Place the slurry suspension obtained in step 2) in a WALL-E beater, mechanically abrasion at 80° C. for 120 minutes, and the weight of the WALL-E beater is 10 kg, to obtain a fiber slurry with a microfiber length of 5-8 mm;

[0030] 4) The fiber slurry obtained in step 3) is dehydrated and air-dried, and then undergoes a fiber opening and loosening process to finally obtain a halogen-free flame-retardant and ablation-resistant fiber material with a high specific surface area. The specific s...

Embodiment 2

[0032] 1) Polyimide fibers were prepared by polycondensation reaction of PMDA, SiDA and BAPPO three monomers in a ratio of 60:40:100, the diameter of the fibers was 15 μm, and the linear density of the tow was 1500 dtex;

[0033] 2) The polyimide fibers obtained in step 1) are mechanically cut to obtain short fibers with a length of 3 cm, and then the short fibers are dispersed in water by a disintegrator to obtain a slurry suspension with a concentration of 3 wt %;

[0034] 3) Put the slurry suspension obtained in step 2) in a WALL-E beater, mechanically abrasion at 80° C. for 60 minutes, and the weight of the WALL-E beater is 10 kg, to obtain a fiber slurry with a microfiber length of 5-10 mm;

[0035] 4) The fiber slurry obtained in step 3) is dehydrated and air-dried, and then undergoes a fiber opening and loosening process to finally obtain a halogen-free flame-retardant and ablation-resistant fiber material with a high specific surface area. The specific surface area of ...

Embodiment 3

[0037] 1) Polyimide fibers are prepared by polycondensation reaction of PMDA, SiDA and BAPPO three monomers in a ratio of 40:60:100, the diameter of the fibers is 20 μm, and the linear density of the tow is 2000 dtex;

[0038] 2) The polyimide fiber obtained in step 1) is mechanically cut to obtain short fibers with a length of 4 cm, and then the short fibers are dispersed in water by a disintegrator to obtain a slurry suspension with a concentration of 1 wt %;

[0039] 3) Place the slurry suspension obtained in step 2) in a WALL-E beater, mechanically abrade it at 50° C. for 120 minutes, with a weight of 5 kg on the WALL-E beater, to obtain a fiber slurry with a microfiber length of 10-20 mm;

[0040] 4) The fiber slurry obtained in step 3) is dehydrated and air-dried, and then undergoes a fiber opening and loosening process to finally obtain a halogen-free flame-retardant and ablation-resistant fiber material with a high specific surface area. The specific surface area of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com