A waste heat utilization system and method of a biomass internal combustion engine

A technology for internal combustion engines and waste heat, applied to internal combustion piston engines, combustion engines, mechanical equipment, etc., can solve problems such as consumption and ineffective conversion of heat, and achieve the effects of ensuring full absorption, full recycling, and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

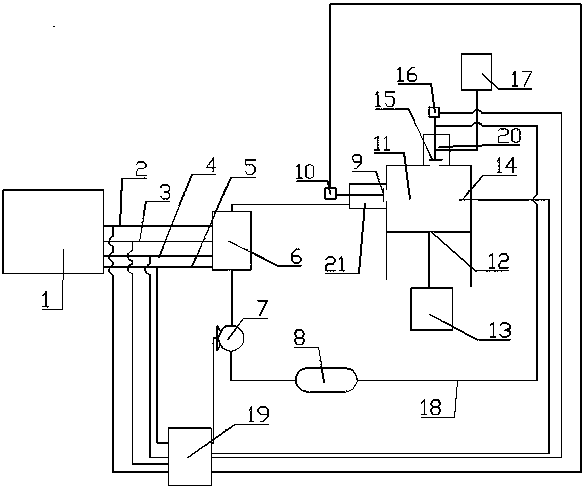

[0044] A waste heat utilization system of a biomass internal combustion engine, such as figure 1 As shown, it includes a condenser 17, a main control ECU 19, an internal combustion engine waste heat recovery unit, a heat exchanger 6, an oil pump 7, a heat conversion unit, an intake solenoid valve 10, an exhaust solenoid valve 16, an oil storage tank 8 and a piston 12.

[0045] The system described in this embodiment is used to recycle the waste heat of the internal combustion engine of the vehicle, wherein the condenser 17 is an existing component in the vehicle, and its temperature is relatively low to realize condensation.

[0046] The main control ECU19 is also an existing component in the vehicle, which includes a single-chip microcomputer (model AT89S51) that can analyze the received signal to obtain a control signal. The analysis method in this embodiment is a mature prior art and does not involve Program improvements.

[0047] There is a thermal chamber 11 in the ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com