Porous-DBR-based InGaN-based resonant cavity enhanced detector chip

A detector chip and resonant cavity technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of increasing the drift time of photogenerated carriers, restricting the response speed of the detector, and the effective thickness of the InGaN layer. Simple and controllable, improved epitaxial quality, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

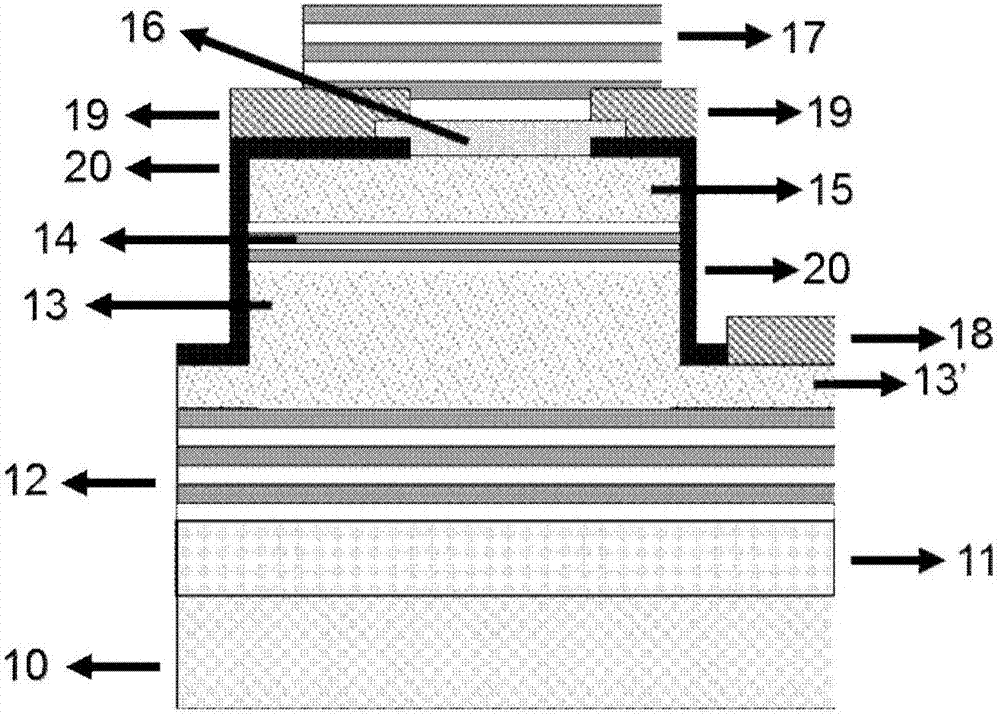

[0023] see figure 1 As shown, the present invention provides a porous DBR-based InGaN-based resonator-enhanced detector chip. This InGaN-based resonant cavity detector structure consists of:

[0024] A substrate 10, a planar sapphire substrate or a patterned sapphire substrate. Other substrates that can be used for epitaxy include silicon, silicon carbide or glass;

[0025] A buffer layer 11 is formed on the upper surface of the substrate 10 . This layer uses high-purity ammonia gas as a nitrogen source, and trimethylgallium or triethylgallium as a Ga source. First, a GaN nucleation layer is grown at a low temperature, and then an unintentionally doped GaN layer is grown at a high temperature. Others that can be used as a buffer layer are graphene or zinc oxide;

[0026] A bottom porous DBR layer 12 is formed on the upper surface of the buffer layer 11 . This layer is obtained by electrochemical etching of alternately lightly and heavily doped GaN layers, the dopant is si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com