Hybrid paper mulberry silage and application thereof

A tree-forming and silage technology, applied in the field of animal husbandry, can solve problems such as low utilization rate of digestion and absorption, difficulty in digesting and absorbing animals, and complex molecular structure of tree-forming leaves, so as to improve immunity and anti-oxidation ability, and improve immunity and antioxidant capacity, and the effect of improving feed utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

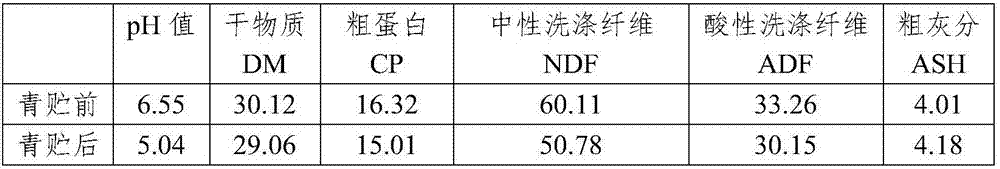

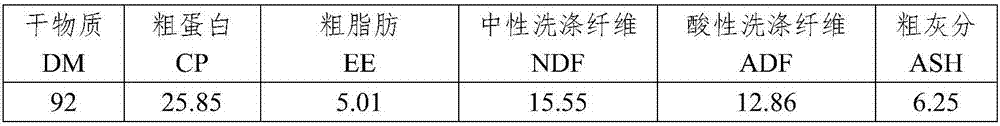

[0023] Before and after embodiment 1 hybrid mulberry silage, the nutrient composition comparison of hybrid mulberry leaf powder

[0024] 1. Comparison method: Dry in an oven at 65°C for 48 hours, take it out and place it at natural temperature for 24 hours, crush it through a 40-mesh standard sieve, and measure dry matter (DM), crude protein (CP), crude fat (EE), Crude ash (ash), neutral detergent fiber (NDF), acid detergent fiber (ADF) content.

[0025] 2. Hybrid mulberry silage and leaf powder are provided by Beijing Jonathan Science and Technology Development Co., Ltd. In July 2015, the mulberry plant grew to about 1.80m, and it was harvested with a green forage harvester, leaving about 20 cm of stubble, and the whole mulberry tree was crushed To 1-2cm, wrap it with a silage wrapper, and use it after 30 days of silage. Each bag of silage weighs about 80 kg. See Table 1 for the nutrients before and after silage.

[0026] Table 1 Hybrid mulberry silage before and after nutri...

Embodiment 2

[0033] Embodiment 2 Hybrid mulberry silage and feeding experiment

[0034] 1. Test time and place

[0035] It was carried out in April 2016 at the Zhongding Animal Husbandry Demonstration Base in Zhaoquanying, Shunyi District, Beijing.

[0036] 2. Test materials

[0037] Hybrid mulberry silage and leaf powder were provided by Beijing Jonathan Technology Development Co., Ltd.

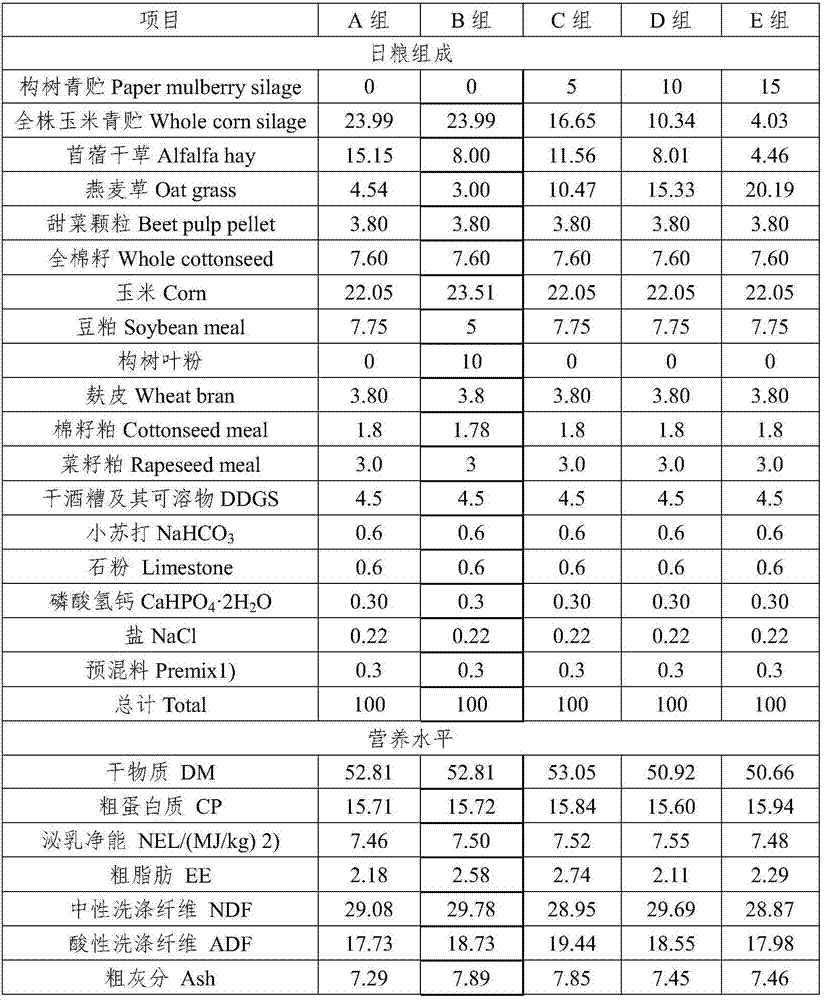

[0038] 3. Experimental design

[0039] Select 90 healthy Holstein cows with lactation days of 128±65 days and milk production of 34.16±0.71kg, and divide them into A, B, C, D, and E according to the principle of basically the same lactation time, milk production and parity. treatment groups, each with 18 heads, in which:

[0040] Group A is the control group, fed with the original TMR diet in the pasture;

[0041]In addition, 4 groups B, C, D, and E are test groups, which are the hybrid mulberry leaf powder group (add 10% in the diet), the hybrid mulberry silage low-dose group (add 5% in the diet), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com