A kind of flexible composite material with sandwich structure and its preparation method and application

A composite material and sandwich technology, applied in the field of forensic science, can solve problems such as unsatisfactory rapid detection and on-site detection, long reaction time, printing ink diffusion, etc., to achieve enhanced fingerprint display effect, wide range of applicable objects, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

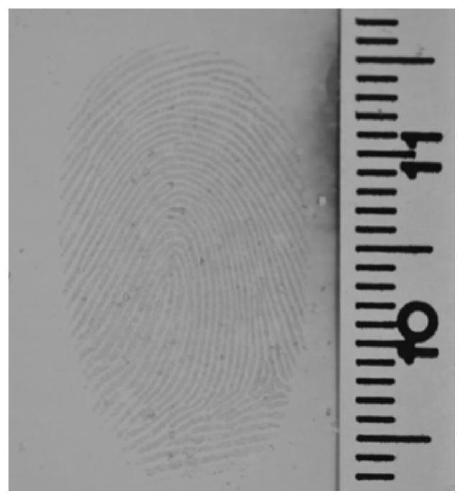

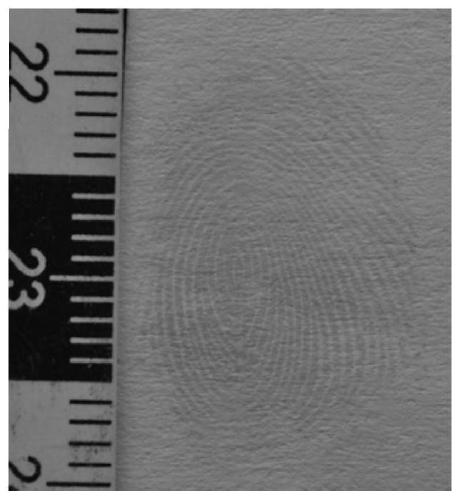

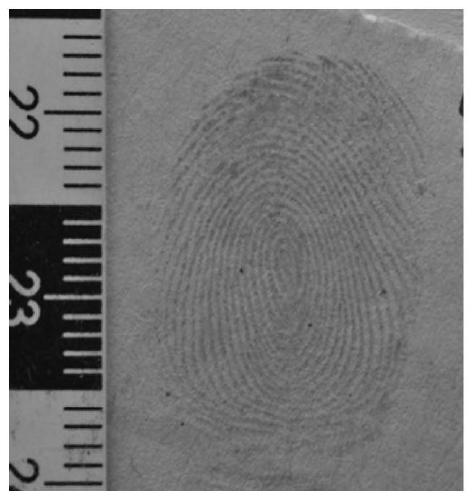

Image

Examples

Embodiment 1

[0023] 1) Mix ninhydrin and ethanol uniformly in a mass ratio of 0.1:10 to obtain a developer, and mix polyvinyl alcohol and water in a mass ratio of 0.1:5 to obtain an emulsion. The developer and emulsion are mixed in a mass ratio of 9 : 1 ratio mixed evenly to obtain the reaction solution;

[0024] 2) Mix iron powder, water, activated carbon, sodium chloride, starch-grafted acrylic acid polymer, and silicon carbide-filled silicone rubber according to the mass ratio of 58:24:5:4:1:9 to obtain a self-heating slurry;

[0025] 3) The reaction solution was mixed at 20 μl / cm 2 The concentration is evenly added dropwise to one side of the polyethylene terephthalate substrate, dried naturally for 20 minutes to form a reaction layer, and then the self-heating slurry is mixed at 40 μg / cm 2 Evenly apply the concentration on the other side of the polyethylene terephthalate substrate, and let it dry naturally for 20 minutes to form a self-heating layer, that is, to obtain a flexible com...

Embodiment 2

[0028] 1) Indandione and ethanol are mixed uniformly in a mass ratio of 0.12:10 to obtain a developer, polyethylene glycol 8000 and water are uniformly mixed in a mass ratio of 0.2:5 to obtain an emulsion, and the developer and emulsion are obtained by The ratio of mass ratio 10:1 is mixed evenly to obtain the reaction solution;

[0029] 2) Mix iron powder, water, activated carbon, sodium chloride, starch-grafted acrylamide polymer, and alumina-filled silicone rubber according to the mass ratio of 56:25:4:5:2:8 to obtain a self-heating slurry ;

[0030] 3) The reaction solution was mixed according to 18 μl / cm 2 The concentration is evenly added dropwise to one side of the polyethylene terephthalate substrate, dried naturally for 30 minutes to form a reaction layer, and then the self-heating slurry is mixed at 50 μg / cm 2 Evenly apply the concentration on the other side of the polyethylene terephthalate substrate, and let it dry naturally for 30 minutes to form a self-heating ...

Embodiment 3

[0033] 1) Mix 1,2-indandione and ethanol uniformly at a mass ratio of 0.08:10 to obtain a developing solution, mix polyethylene glycol 6000 and water at a mass ratio of 0.1:5 to obtain an emulsion, and develop Liquid and emulsified liquid are mixed evenly in the ratio of mass ratio 8:1 to obtain reaction liquid;

[0034] 2) Mix iron powder, water, activated carbon, sodium chloride, polyacrylic superabsorbent polymer, and zinc oxide filled silicone rubber according to the mass ratio of 57:24:5:3:1:10 to obtain self-heating slurry ;

[0035] 3) The reaction solution was mixed at 23 μl / cm 2 The concentration of the polyimide substrate is evenly added dropwise to one side of the polyimide substrate, and it is naturally dried for 40 minutes to form a reaction layer, and then the self-heating slurry is mixed at 70 μg / cm 2 The concentration of the polyimide substrate is evenly applied to the other side of the polyimide substrate, and it is naturally dried for 40 minutes to form a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com