Preparation method for magnetic graphene oxide and application

A technology of stone oxide and graphene, applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc., to achieve the effect of wide source of raw materials and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1). Preparation of pre-oxidized graphite powder

[0023] Weigh 6g of graphite powder, 5.0g of NaNO3 and 30g of KMnO4, dissolve them in the reaction vessel with an appropriate amount of ultrapure water, and assemble the reaction apparatus. Add 500ml of ultrapure water, set the reaction temperature to 0°C, and the rotation speed to 205 / rpm, react for 4 hours, and add ice once every 20 minutes. After 4 hours the reaction was suspended, the ice was removed and tap water was added for heating the water. Adjust the temperature to 35°C and react for 2h. Add 500ml ultrapure water to the reactant, and react for 1h. After the reaction was completed, 1000ml of ultrapure water was added (stirring while adding), and then 40ml of H2O2 was added and stirred in the reactor for 2h. Wash with ultrapure water until neutral, dry for use.

[0024] (2). Preparation of graphene oxide

[0025] Weigh 6g pre-oxidized graphite powder, 5g NaNO3, 30g KMnO4, and assemble the reaction apparatus...

Embodiment 2

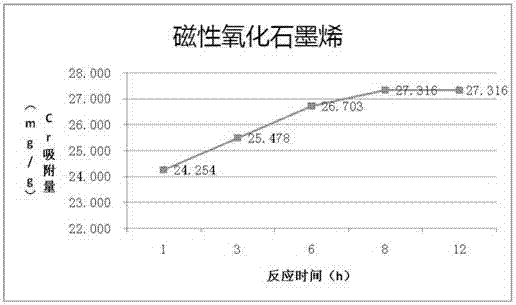

[0029] (1). Treat chromium-containing wastewater and explore the optimal reaction time:

[0030] Get 50ml of 10mg / L Cr6+ solution in 5 Erlenmeyer flasks respectively, add 2ml of magnetic graphene oxide, adjust the rotating speed to 200rpm, and the temperature is 25°C (normal temperature), respectively react 1, 3, 6, 8, 12 hours.

[0031] From the experimental results as attached figure 1 As shown, the adsorption capacity tends to be saturated when the reaction time reaches 8h, and the optimum reaction time is 8h at present.

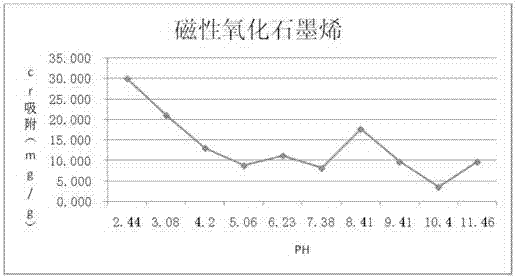

[0032] (2). Treat chromium-containing wastewater and explore the pH of the optimal reaction environment:

[0033] Take 40-60ml of 10mg / L Cr6+ solution in 9 Erlenmeyer flasks and adjust the pH to 2, 3, 4, 5, 6, 7, 8, 9, 10, 11. Add 1ml of magnetic graphene oxide, react in a shaker for 8h (preferred reaction time), adjust the rotation speed to 200rpm, and the temperature to 25°C (normal temperature).

[0034] From the experimental results as attached ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com