Efficient nitrogen and phosphorus removal granular preparation and production process thereof

A granular preparation, denitrification and phosphorus removal technology, applied in water treatment parameter control, water/sludge/sewage treatment, water pollutants, etc., can solve the problems of low porosity, high energy consumption, etc., to improve utilization efficiency, energy The effect of low consumption and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

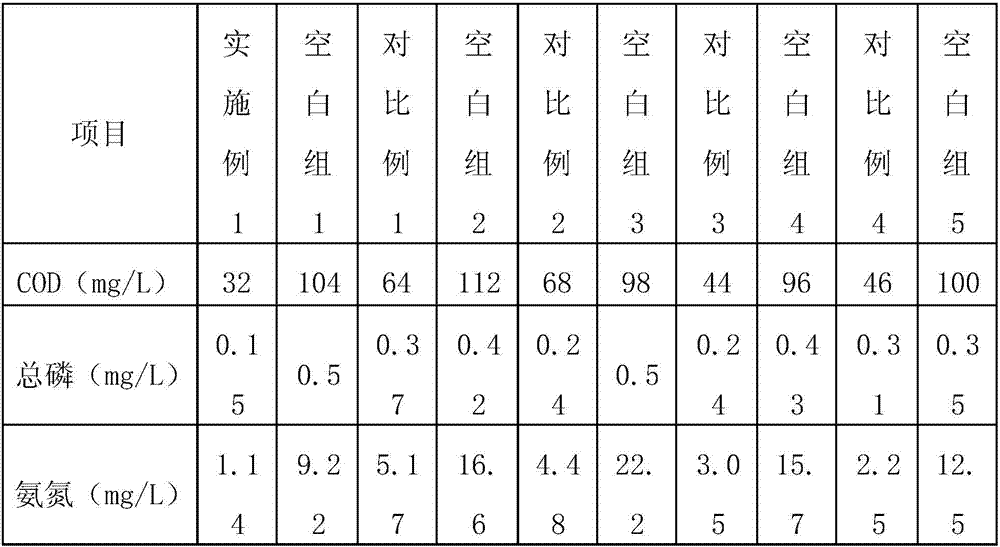

Examples

Embodiment 1

[0031] (1) mixed

[0032] Based on the total weight of the water purifying agent, mix potassium ferrate, bentonite, disodium edetate, and cement according to the weight ratio of 100g, 100g, 4g, and 50g, add to the mixer, and control the temperature at 25-30°C , and stirred for 20-30min under the protection of an inert gas.

[0033] If the bentonite, potassium ferrate, and cement used are solid, they need to be crushed into powder and then mixed.

[0034] (2) Hole forming

[0035] Sodium lauryl sulfate whipping agent is configured into the aqueous solution that concentration is 3g / L earlier, then the sodium lauryl sulfate aqueous solution is added according to 1% weight ratio and joins in the powder mixture mixed in the above-mentioned step (1), Add it into a mixer, control the temperature at 25-30°C, stir for 20-30 minutes under the protection of an inert gas, then use a granule press to produce a granule product, and finally dry it to form a granule preparation with a certa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com