Oxidized-graphene concrete composite material resisting chloride ion penetration and preparation method thereof

A composite material and graphene technology, which is applied in the field of building materials, can solve problems such as insufficient durability and corrosion of concrete materials by chloride salts, and achieve the effects of good resistance to chloride ion penetration, increased content, and low content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

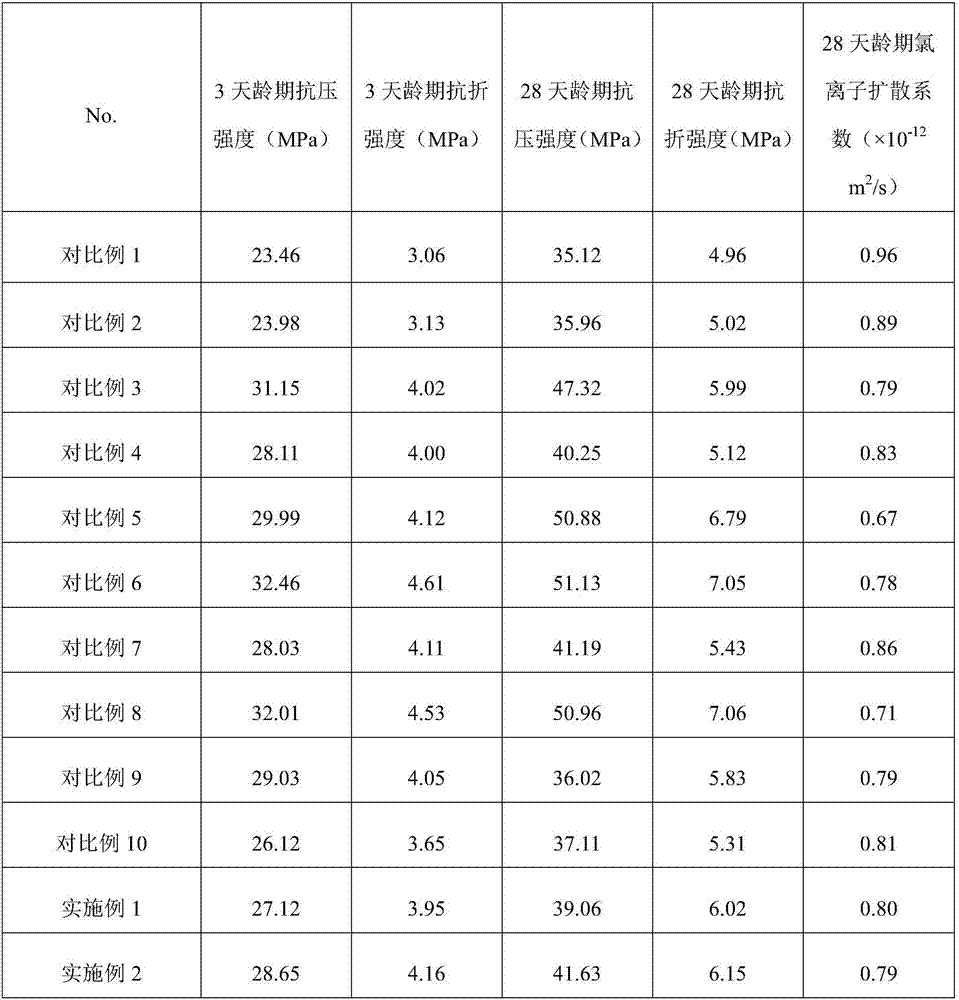

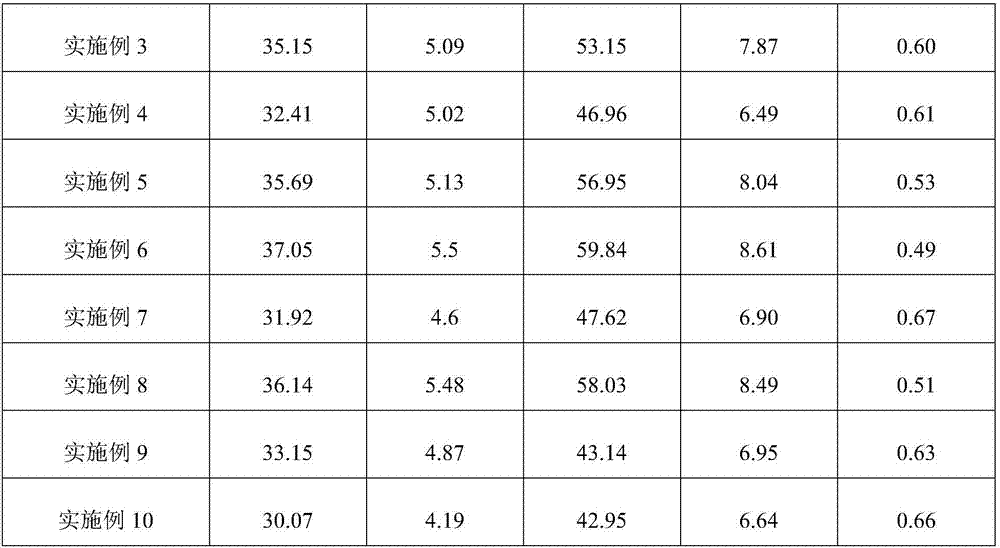

Examples

Embodiment 1

[0054] 1) Weigh 200g of graphene oxide, add it into 150L solvent prepared by water and ethanol according to the ratio of 5:1, stir evenly, disperse ultrasonically for 100min, adjust the Ph value of the above solution to 5.8 with glacial acetic acid, and then add to the Slowly add 60Kg of 1% KH550 silane coupling agent dropwise in the solution, stir evenly with a stirrer at a high speed, the rotating speed is 1000rpm, and the stirring time is 1h, and the Ph value of the modified graphene oxide suspension is adjusted to 5.9 with NaOH solution. use.

[0055] 2) Then weigh 120L of the modified graphene oxide suspension in step 1), add 32kg of silicon powder, and dry it in a forced air drying oven at 100°C to a constant weight before adding the silicon powder. Then move the reaction device added with silica fume-modified graphene oxide suspension into a water bath at 60°C, heat and stir for 45 minutes, after the reaction is completed, the graphene oxide-modified silica fume solutio...

Embodiment 2

[0059] 1) Take 600g of graphene oxide by weighing, join in the 500L solvent that water and ethanol are prepared according to the ratio of 5:1, after stirring evenly, ultrasonic dispersion 100min, the Ph value of above-mentioned solution is adjusted to 5.5 with glacial acetic acid, then add to this Slowly add 60kg of 5% KH550 silane coupling agent dropwise in the solution, stir evenly with a stirrer at a high speed, the rotating speed is 1200rpm, and the stirring time is 2h, and the Ph value of the modified graphene oxide suspension is adjusted to 5.5 with KOH solution. use.

[0060] 2) Then weigh 300L of the modified graphene oxide suspension in step 1), add 40kg of silicon powder, and dry it in a forced air drying oven at 100°C to constant weight before adding the silicon powder. Then move the reaction device added with silica fume-modified graphene oxide suspension into a water bath at 80°C, heat and stir for 55 minutes, after the reaction is completed, the graphene oxide-mo...

Embodiment 3

[0064] 1) Weigh 1000g of graphene oxide, add it into 800L solvent prepared by water and ethanol according to the ratio of 4:1, stir evenly, disperse ultrasonically for 80min, adjust the Ph value of the above solution to 6.0 with glacial acetic acid, and then add to the Slowly add 500kg of 1% KH560 silane coupling agent dropwise in the solution, stir evenly with a stirrer at a high speed, the rotating speed is 1500rpm, the stirring time is 1.2h, and the Ph value of the modified graphene oxide suspension is adjusted to 5.0 with NaOH solution, stand-by.

[0065] 2) Then weigh 280L of the modified graphene oxide suspension in step 1), add 30kg of silicon powder, and dry it in a blast drying oven at 100°C to a constant weight before adding the silicon powder. Then move the reaction device added with silica fume-modified graphene oxide suspension into a water bath at 55°C, heat and stir for 55 minutes, after the reaction is completed, the graphene oxide-modified silica fume solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com