Mould-proof antibacterial coating and preparation method thereof

A technology of antifungal and antibacterial coatings, applied in antifouling/underwater coatings, microsphere preparation, microcapsule preparations, etc., can solve problems such as limited application, unstable efficacy of essential oils, etc., to improve coating ability, Improve the pores and pore structure, eliminate the effect of odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

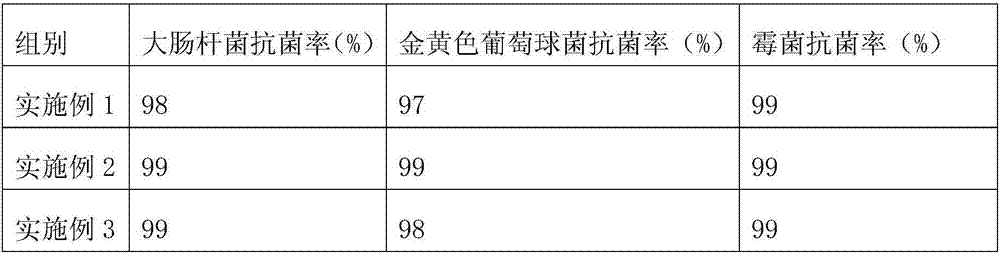

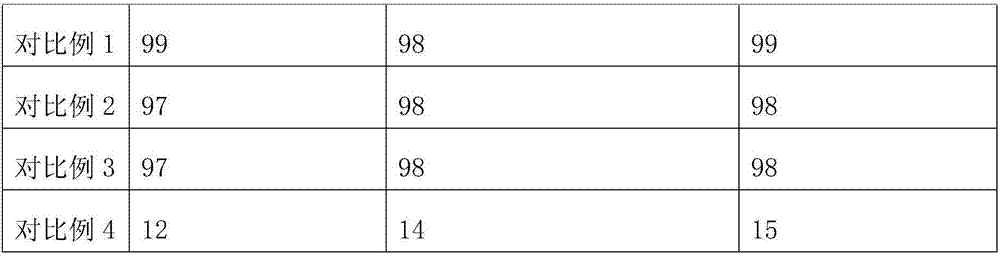

Examples

Embodiment 1

[0029] A mildew-proof and antibacterial coating is prepared from the following raw materials in parts by weight:

[0030] 100 parts of vinegar-acrylic emulsion, 50 parts of alkyd resin, 6 parts of wetting and dispersing agent, 20 parts of pigment, 20 parts of zeolite powder, 40 parts of diatomite, 20 parts of sepiolite powder, 4 parts of polyacrylamide, film-forming aid 5 parts, 15 parts of microcapsule bactericide, and 2 parts of defoamer; wherein, the particle diameters of zeolite powder, diatomaceous earth and sepiolite powder are all 0.1-1 μm.

[0031] The preparation method of above-mentioned coating, comprises the following steps:

[0032] (1) Organic modification of bentonite: immerse sodium-based bentonite in dilute hydrochloric acid solution with a mass concentration of 0.6%, react for 6 hours at a water bath temperature of 40-50°C and a stirring speed of 400r / min, and then suction filter And wash the filter residue with deionized water until it is neutral, dry it at...

Embodiment 2

[0036] A mildew-proof and antibacterial coating is prepared from the following raw materials in parts by weight:

[0037] 120 parts of vinegar-acrylic emulsion, 85 parts of alkyd resin, 8 parts of wetting and dispersing agent, 32 parts of pigment, 22 parts of zeolite powder, 45 parts of diatomite, 25 parts of sepiolite powder, 5 parts of polyacrylamide, film-forming aid 7 parts, 18 parts of microcapsule bactericide, and 3 parts of defoamer; wherein, the particle diameters of zeolite powder, diatomaceous earth and sepiolite powder are all 0.1-1 μm.

[0038] The preparation method of above-mentioned coating, comprises the following steps:

[0039] (1) Organic modification of bentonite: the sodium bentonite is immersed in a dilute hydrochloric acid solution with a mass concentration of 0.8%, reacted for 5.5h at a water bath temperature of 40-50°C and a stirring speed of 350r / min, and then pumped Filter and wash the filter residue with deionized water until neutral, dry and pulve...

Embodiment 3

[0043] A mildew-proof and antibacterial coating is prepared from the following raw materials in parts by weight:

[0044] 150 parts of vinegar-acrylic emulsion, 100 parts of alkyd resin, 10 parts of wetting and dispersing agent, 40 parts of pigment, 30 parts of zeolite powder, 50 parts of diatomaceous earth, 30 parts of sepiolite powder, 6 parts of polyacrylamide, film-forming aid 10 parts, 20 parts of microcapsule bactericide, and 4 parts of defoamer; wherein, the particle diameters of zeolite powder, diatomaceous earth and sepiolite powder are all 0.1-1 μm.

[0045] The preparation method of above-mentioned coating, comprises the following steps:

[0046] (1) Organic modification of bentonite: immerse sodium-based bentonite in dilute hydrochloric acid solution with a mass concentration of 1.0%, react for 5 hours at a water bath temperature of 40-50°C and a stirring speed of 400r / min, and then suction filter And wash the filter residue with deionized water until it is neutra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com