Flying dust inhibitor based on bacillus pasteurii culture and use method

A pasteurized bacteria and inhibitor technology, applied in the field of dust inhibitor, can solve problems such as environmental deterioration, pollution, natural degradation, etc., and achieve the effects of improving rolling resistance, improving wind resistance, and long duration of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The first step: the CO (NH 2 ) 2 with CaCl 2 Put into proportion water to mix evenly.

[0031] The second step: adding the Bacillus pasteurian bacteria solution.

[0032] Step 3: Mix quickly and evenly and then spray on the road surface and the surface of the stockpile.

[0033] The CO(NH 2 ) 2 with CaCl 2 About 123kg, added to 0.9m 3 After stirring well, add about 0.1m 3 Pasteurella solution (bacterial concentration is 1.0×10 8 ~1.3×10 8 cell / mL), after rapid mixing to 2000m 2 The urban pavement of left and right sides is sprayed, and implementation result shows, the bacillus pasteurei solution that weight ratio is 9.00%, the CO(NH of 4.20% 2 ) 2 , 7.90% CaCl 2 When, the TSP within 7 days after spraying is 0.30mg / m 3 , within the third-grade standard of the ambient air quality standard; the weight ratio is 11.00% of Bacillus pasteurian solution, 4.40% of CO (NH 2 ) 2 , 8.05% CaCl 2 , the TSP within 7 days after spraying was 0.27mg / m 3 , within the thi...

Embodiment 2

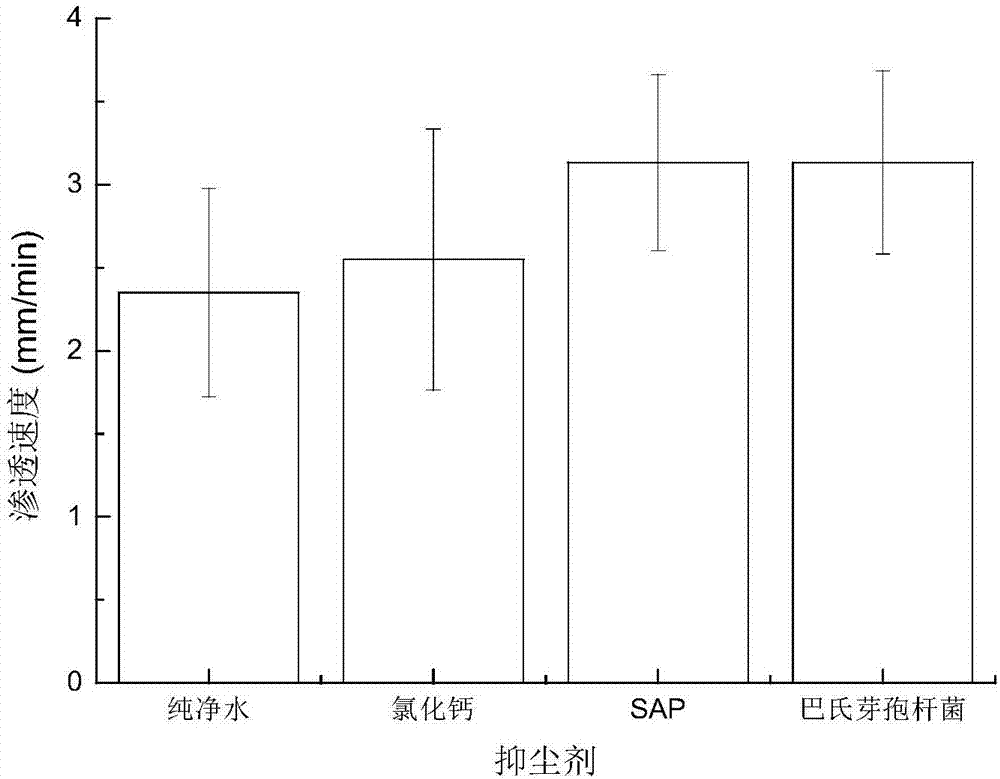

[0035] Embodiment 2: the penetration rate of dust suppressant

[0036] First put a certain amount of pulverized coal into a test tube with a diameter of φ×h of 20×200mm, tamp the pulverized coal with glass rods so that the height of the pulverized coal in the test tube is 15cm, and then fix it on the test tube rack; finally slowly Add 2mL of dust suppressant solution, slowly drop it into the glass tube filled with coal powder, and record the penetration depth of the solution within 20 minutes. Under the same conditions, the faster the penetration rate of the solution, the better the permeability of the solution.

[0037] From figure 1 It can be seen that SAP and Bacillus pasteurian dust suppressant have the largest penetration depth in a short period of time, and the speed of wetting the coal powder is faster, indicating that their wetting performance is stronger. After the dust suppressant solution is sprinkled on the coal powder, It can quickly wet the coal powder with a c...

Embodiment 3

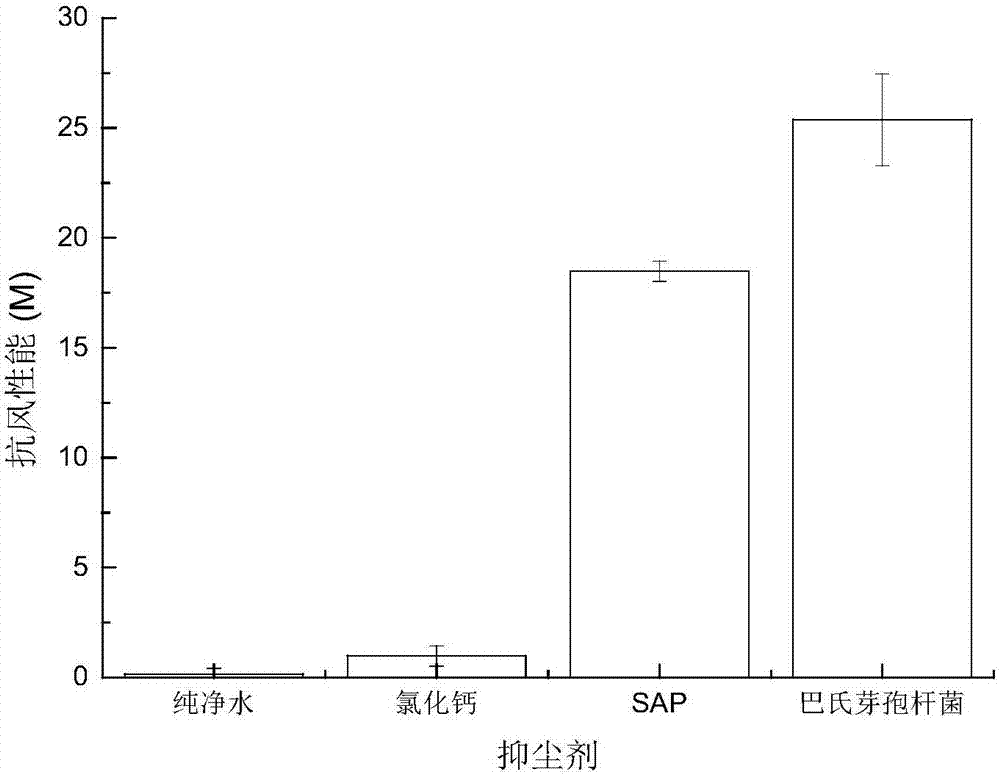

[0038] Embodiment 3: the anti-wind performance of dust suppressant

[0039] First weigh the quality of the φ90mm petri dish, pour 15mL dust suppressant solution evenly on the petri dish, and measure its weight;

[0040] Conduct a wind resistance test on the dust suppressant (use the FS40-B3B Midea 400mm mechanical floor fan at the third gear to blow the dust suppressant, the rotating shaft of the fan blade is facing the petri dish, and blow at 1m from the side of the petri dish for 8h), measure the The quality of the dish, and calculate the wind resistance index according to the following formula. The wind resistance index reflects the weight loss of the dust suppressant under the condition of light wind. The higher the wind resistance index, the stronger the ability of the dust suppressant to retain moisture under strong wind conditions, and the hardened layer is not easy to be blown by the wind. The effective dust suppression time is longer. The calculation formula of wind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com