Composite oxygen carrier as well as preparation method and application thereof to gasification of solid fuel

A technology of solid fuel and oxygen carrier, applied in the direction of fuel, fuel additive, hydrogen separation using solid contact, etc., can solve the problem of difficult coal high conversion rate absorption, etc., achieve low cost, good anti-wear performance, anti-sintering ability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] The fresh olivine was crushed and sieved to a particle size of 0.38-0.83mm, and placed in a muffle furnace at 900°C for 4h. Then place it in the configured saturated Cu(NO 3 ) 2 The solution was immersed in an equal volume method for 24 hours, and then placed in a muffle furnace for calcination at 900°C for 4 hours to obtain the olivine copper-carrying oxygen carrier required for this experiment.

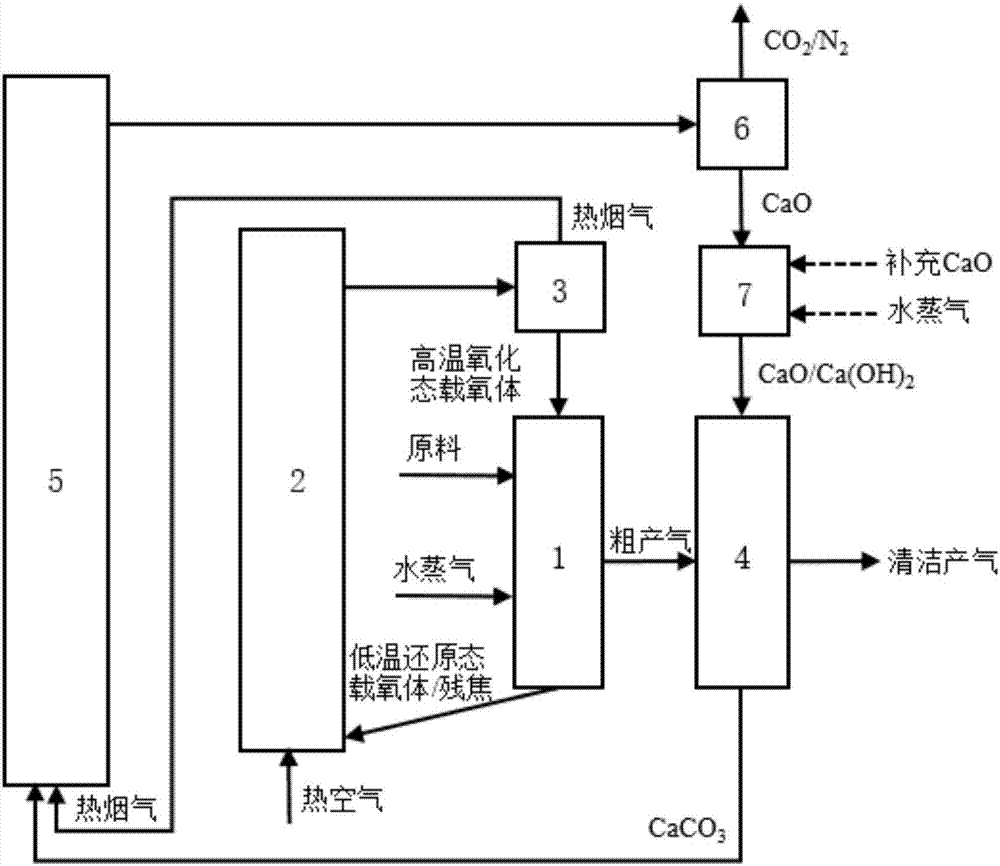

[0029] In such figure 1 In the gasification experiment device shown, the gasification of coal char is performed. The raw material enters from the feed port on the fuel reactor 1, mixes with the high-temperature oxidized oxygen carrier from the first gas-solid separator 3, and undergoes gasification reaction under the action of the water vapor introduced at the same time. The main components are H 2 , CO, and CO 2 The mixed gas. The residual fuel and the oxygen carrier after the reaction enter the air reactor 2 and are ascended by the action of hot air. In this process, the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com