Method for improving electrochemical performance of high-nickel ternary positive electrode material of lithium ion battery

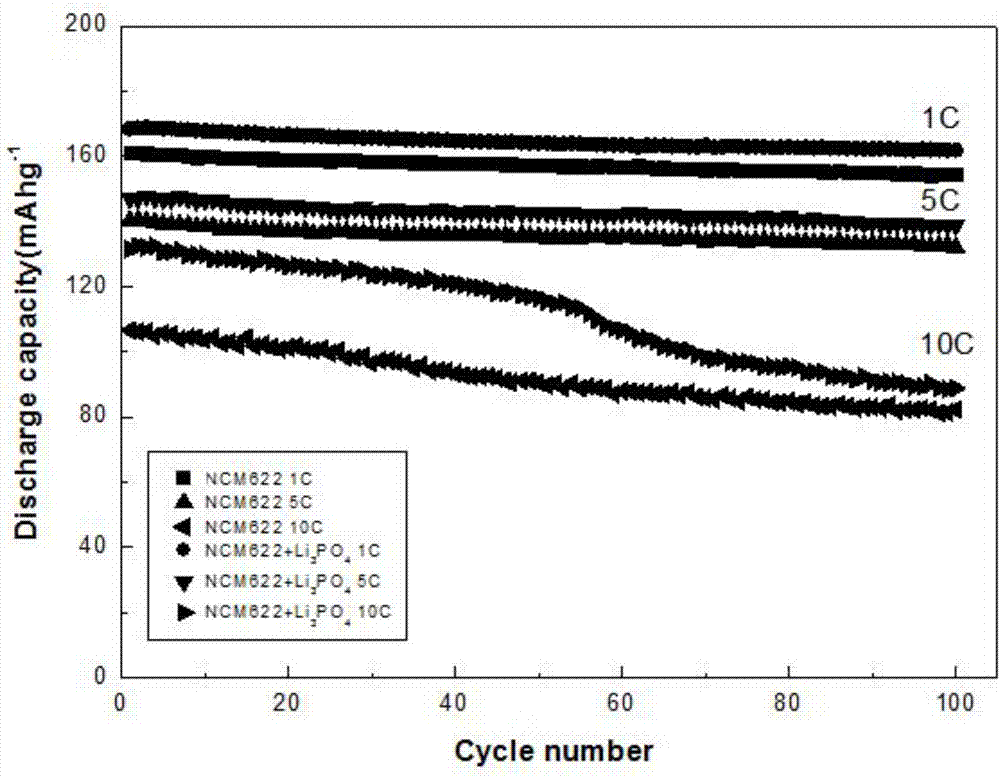

A lithium-ion battery and positive electrode material technology, applied in the field of lithium ion positive electrode material preparation, can solve the problems of large reversible capacity loss, high storage condition requirements, and coating dependence, so as to improve electrochemical performance, promote ion transmission, and avoid direct The effect of contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

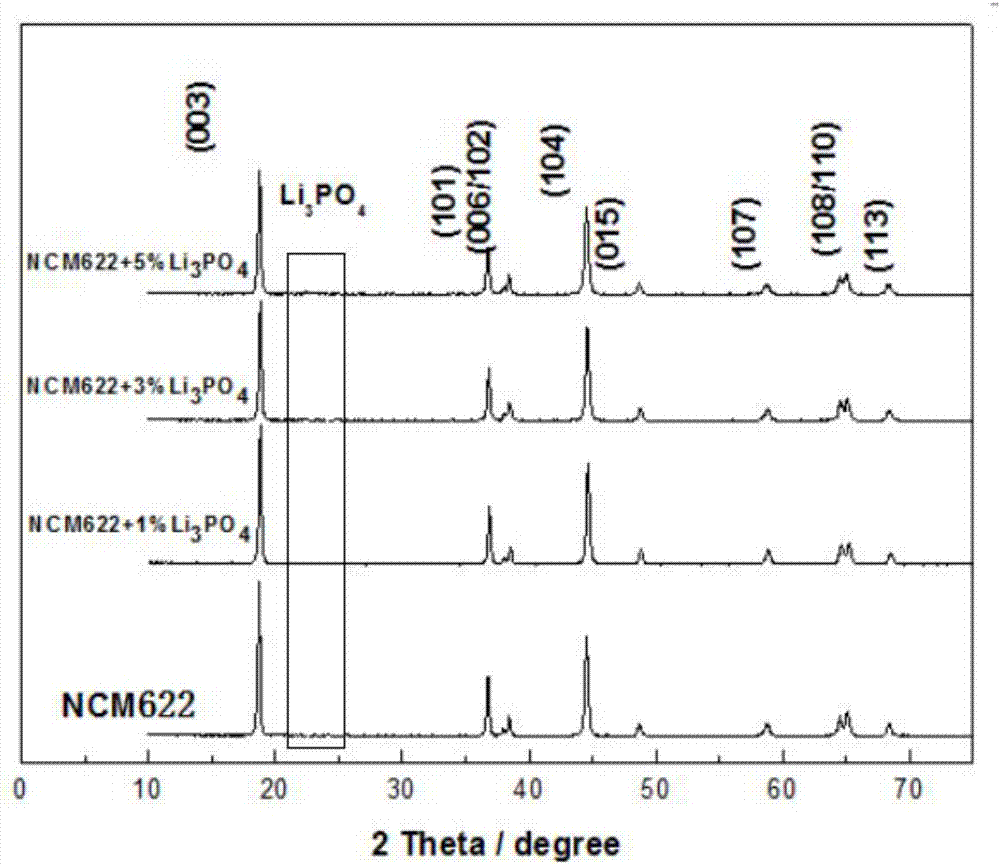

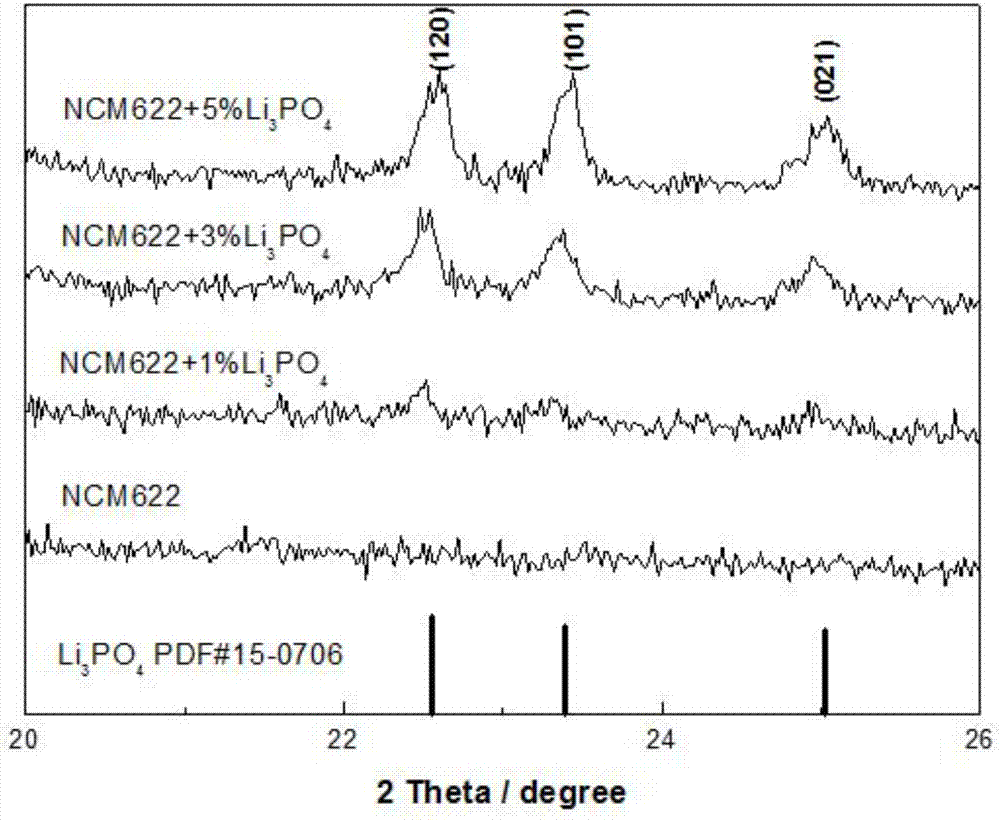

[0026] A modification method for improving the electrochemical performance of high-nickel ternary positive electrode materials for lithium-ion batteries, the specific steps are as follows

[0027] 1) Dissolve 0.1g of ammonium dihydrogen phosphate in deionized water, stir and dissolve at room temperature, the concentration of ammonium dihydrogen phosphate is 50mg / L;

[0028] 2) Add 0.5gNi 0.6 co 0.2 mn 0.2 (OH) 2 The precursors were placed in two containers respectively, and then 0.5ml and 1.5ml of the solution in step 1) were added respectively, and the solution was evaporated to dryness under magnetic stirring to obtain Ni 0.6 co 0.2 mn 0.2 (OH) 2 Precursor, the stirring speed is about 10rpm;

[0029] 3) 2) the resulting Ni with ammonium dihydrogen phosphate coating layer 0.6 co 0.2 mn 0.2 (OH) 2 The precursor was dried in a vacuum oven at 80°C for 3 hours;

[0030] 4) 3) Ni with ammonium dihydrogen phosphate coating layer after drying 0.6 co 0.2 mn 0.2 (OH) 2...

Embodiment 2

[0033] A modification method for improving the electrochemical performance of high-nickel ternary positive electrode materials for lithium-ion batteries, the specific steps are as follows

[0034] 1) Dissolve 0.1g of diammonium hydrogen phosphate in deionized water, stir and dissolve at room temperature, the concentration of diammonium hydrogen phosphate is 80mg / L;

[0035] 2) Add 0.5gNi 0.8 co 0.1 mn 0.1 (OH) 2 The precursors were placed in two containers respectively, and then 0.4ml and 1.0ml of the solution in step 1) were added respectively, and the solution was evaporated to dryness under magnetic stirring to obtain Ni 0.8 co 0.1 mn 0.1 (OH) 2 Precursor, the stirring speed is about 10rpm;

[0036] 3) 2) the resulting Ni with diammonium hydrogen phosphate coating 0.8 co 0.1 mn 0.1 (OH) 2 The precursor was dried in a vacuum oven at 80°C for 3 hours;

[0037] 4) Ni with diammonium hydrogen phosphate coating layer after 3) drying 0.8 co 0.1 mn 0.1 (OH) 2 The p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com