Preparation method and application of efficient hydrophilic modified anti-pollution polyether sulfone film

A polyethersulfone membrane and hydrophilization technology, which is applied in the field of membrane separation, can solve the problems of increased operating cost, decreased membrane separation efficiency, serious membrane fouling, etc., and achieves the effect of novel structure, improved hydrophilicity and anti-pollution performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method and application of a high-efficiency hydrophilized modified anti-fouling polyethersulfone membrane, the operation steps are as follows:

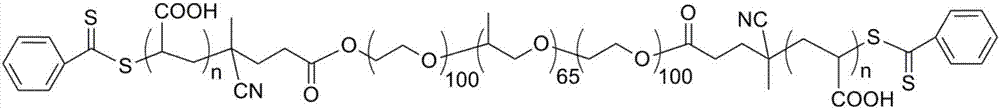

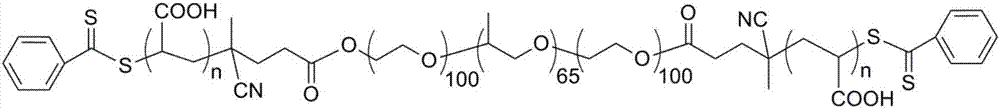

[0029] (1) Synthesis of additive PAA-F127-PAA:

[0030] Add 0.5g of CPADB-F127-CPADB, 2.5mg of azobisisobutyronitrile, and 0.88g of acrylic acid into the reactor, dissolve them in 11.5g of N,N-dimethylformamide, and remove the Oxygen, protected by nitrogen, stirred and reacted at 50°C for 24 hours to prepare a hydrophilic block copolymer PAA-F127-PAA;

[0031] (2) Preparation of physically blended modified PES / PAA-F127-PAA film:

[0032] Polyethersulfone (PES) was used as the base film material, PAA-F127-PAA was used as the additive, and N,N-dimethylformamide was used as the solvent. The membrane liquid was stirred at 60°C for 2 hours, and then the film was scraped after standing still for defoaming for 12 hours. The coagulation bath was a 60°C water bath to obtain a blended modified PES / PAA-F127-PAA film.

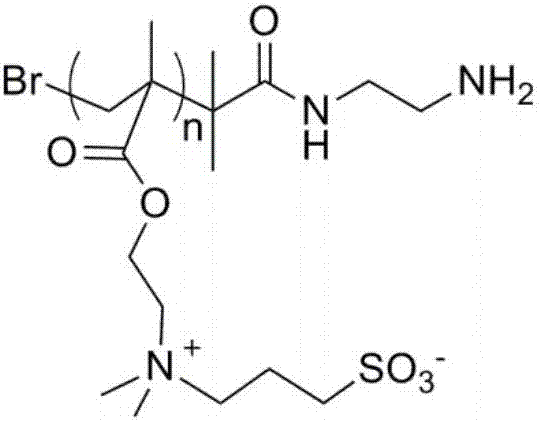

[0...

Embodiment 2

[0040] A preparation method and application of a high-efficiency hydrophilized modified anti-fouling polyethersulfone membrane, the operation steps are as follows:

[0041] (1) Synthesis of additive PAA-F127-PAA:

[0042] Add 0.5g of CPADB-F127-CPADB, 1.9mg of azobisisobutyronitrile, and 2.2g of acrylic acid into the reactor, dissolve them in 19.16g of N,N-dimethylformamide, and remove the Oxygen, protected by nitrogen, stirred and reacted at 70 ° C for 12 hours to prepare a hydrophilic block copolymer PAA-F127-PAA;

[0043] (2) Preparation of physically blended modified PES / PAA-F127-PAA film:

[0044] Polyethersulfone (PES) was used as the base film material, PAA-F127-PAA was used as the additive, and N,N-dimethylacetamide was used as the solvent. The membrane solution was stirred at 20°C for 12 hours, left to defoam for 4 hours, and then scraped off. The coagulation bath was an ethanol bath at 20°C to obtain a blended modified PES / PAA-F127-PAA film.

[0045] (3) Strongly ...

Embodiment 3

[0052] A preparation method and application of a high-efficiency hydrophilized modified anti-fouling polyethersulfone membrane, the operation steps are as follows:

[0053] (1) Synthesis of additive PAA-F127-PAA:

[0054] Add 0.5g of CPADB-F127-CPADB, 2.5mg of azobisisobutyronitrile, and 0.8g of acrylic acid into the reactor, dissolve them in 13.49g of N,N-dimethylformamide, and remove the Oxygen, protected by nitrogen, stirred and reacted at 90°C for 4 hours to prepare a hydrophilic block copolymer PAA-F127-PAA;

[0055] (2) Preparation of physically blended modified PES / PAA-F127-PAA film:

[0056] Polyethersulfone (PES) was used as the base film material, PAA-F127-PAA was used as the additive, and dimethyl sulfoxide was used as the solvent. Stir for 7 hours at ℃, stand for 8 hours for defoaming, and then scrape the film. The coagulation bath is a mixed bath of water and ethanol with a volume ratio of 4:1 at 4 ℃ to obtain a blended modified PES / PAA-F127-PAA film.

[0057] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com