Tobacco atmosphere intelligent regulating device and tobacco storage device containing same

A technology of intelligent adjustment and tobacco, which is applied in packaging under vacuum/special atmosphere, packaging objects under special gas conditions, packaging, etc., can solve the problem of not being able to maintain the tobacco atmosphere for a long time, changes in the taste of tobacco smoking, and short retention time, etc. problem, to achieve the effect of enhancing moisturizing and anti-mildew function, improving core competitiveness, and ensuring fullness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Prepare the conditioning liquid components in the tobacco atmosphere intelligent regulating device:

[0051] Mix the following materials by weight percentage:

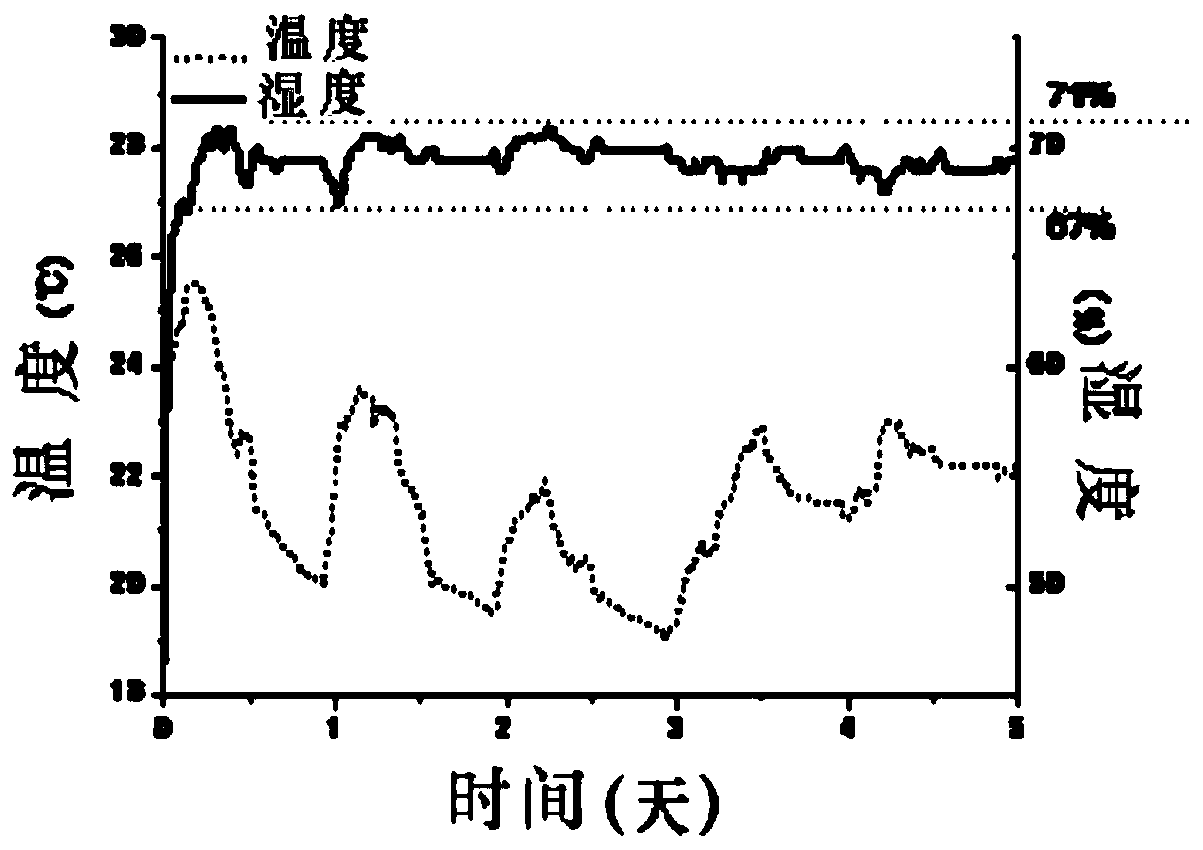

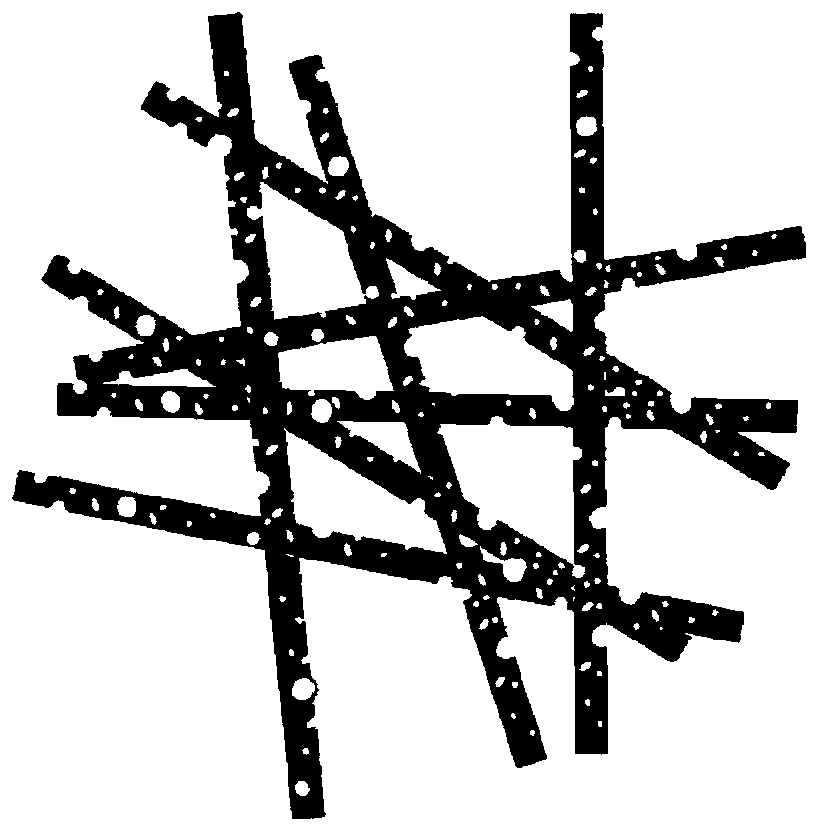

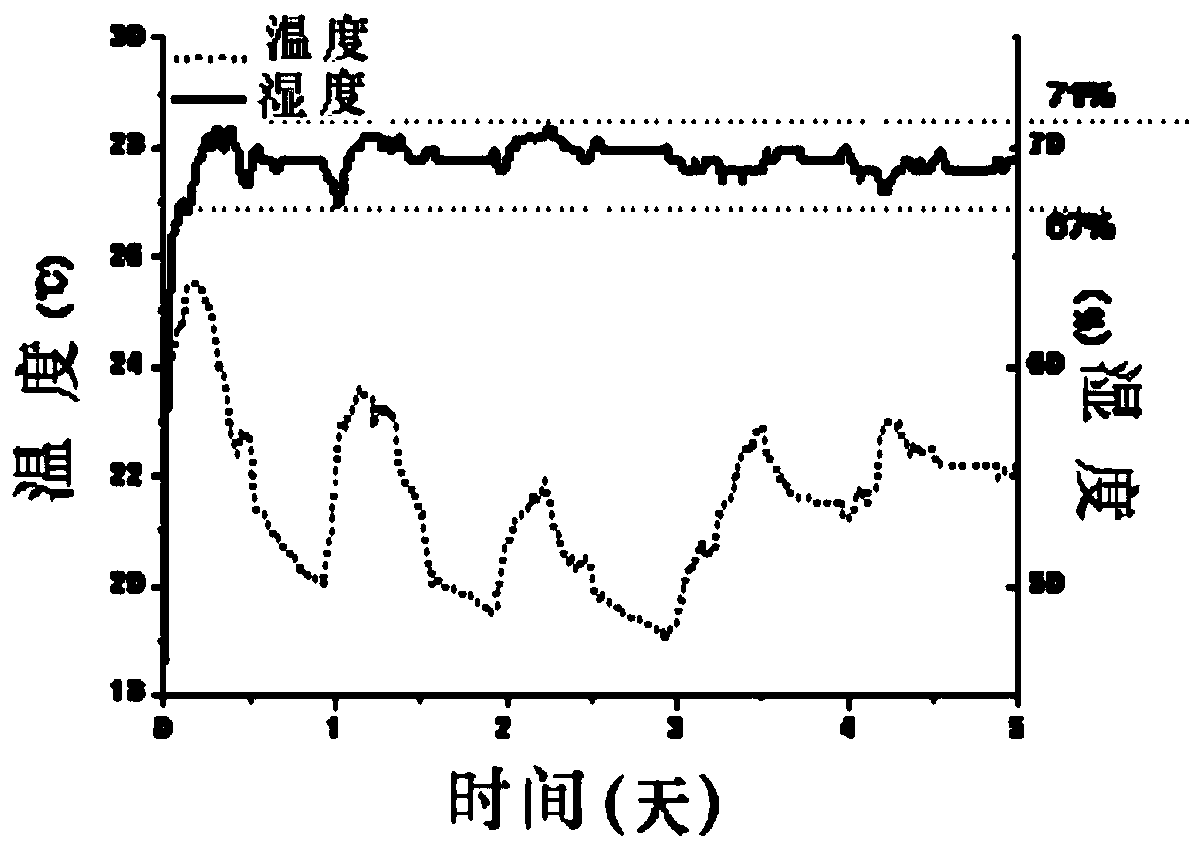

[0052] Tobacco extract 3% (neophytadiene 20%, ethyl palmitate 30%, methyl palmitate 50%), water 45%, salt 50% (including sodium formate 60%, sodium citrate 40%), thickening Agent 0.6% (pregelatinized tapioca starch), mint essence 0.6%, specific adsorbent 0.8% (attapulgite). The material of the air-permeable and liquid-tight polymer membrane is polyurethane polymer membrane, the thickness of the polymer membrane is 10 μm, and the pore diameter is 400±20 nm. The polymer membrane was wrapped with an absorbent layer of cellulose membrane material with a thickness of 75 μm. The polymer film wrapped with the adsorption layer is made into a sealed bag with the same size as the cigarette. Fill it with the conditioning liquid and mix well. In order to prevent the conditioning fluid from being volatile and wasted befo...

Embodiment 2

[0057] Prepare the conditioning liquid components in the tobacco atmosphere intelligent regulating device:

[0058] The following materials are mixed according to weight percentage: tobacco extract 3.5% (neophytadiene 50%, methyl palmitate 25%, ethyl oleate 25%), water 38.5%, salt 55% (including sodium chloride 40% %, magnesium chloride 60%), thickener xanthan gum 0.8%, apple essence 0.7%, specific adsorbent mesoporous silica 1.5%. Polytetrafluoroethylene polymer is used as the air-permeable and liquid-tight polymer membrane, the thickness of the polymer membrane is 20 μm, and the pore diameter is 200±30 nm. The polymer film is wrapped with an adsorption layer of activated carbon material with a thickness of 90 μm. The polymer film wrapped with the adsorption layer is made into a sealed bag with the same size as the cigarette, and the conditioning liquid components are filled into it, mixed evenly, and a layer of polyethylene material airtight film is pasted on the outside of...

Embodiment 3

[0063] Prepare the conditioning liquid components in the tobacco atmosphere intelligent regulating device:

[0064] Mix the following materials according to weight percentage: tobacco extract 4% (60% ethyl linoleate, 10% nicotine, 30% methyl linolenate), 35% water, 60% salt (including 30% sodium acetate, magnesium chloride 70%), thickener gum 0.8%, sandalwood essence 0.1%, specific adsorbent mesoporous silica 0.1%.

[0065] Polytetrafluoroethylene polymer is used as the air-permeable and liquid-proof polymer membrane, the thickness of the polymer membrane is 25 μm, and the pore diameter is 600±35 nm. The polymer film is wrapped with an adsorption layer of an adsorption paper material (cellulose, hemicellulose, and lignin as the main components) with a thickness of 80 μm. The polymer film wrapped with the adsorption layer is made into a sealed bag with the same size as the cigarette. Fill the conditioner into it, mix well, and paste a layer of polyethylene material air-tight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com