Core-shell heterogeneous lithium-ion battery composite positive electrode material composed of layered lithium-rich manganese-based and spinel-type lithium manganate and preparation method thereof

A technology for compounding cathode materials and lithium ion batteries, which is applied to battery electrodes, circuits, structural parts, etc., can solve problems such as difficulty in controlling the uniformity of slurry mixing, affecting the electrochemical performance of electrode pieces and batteries, and uneven distribution of cathode active materials. , to achieve the effect of easy industrial large-scale promotion and application, eliminating the production process and excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

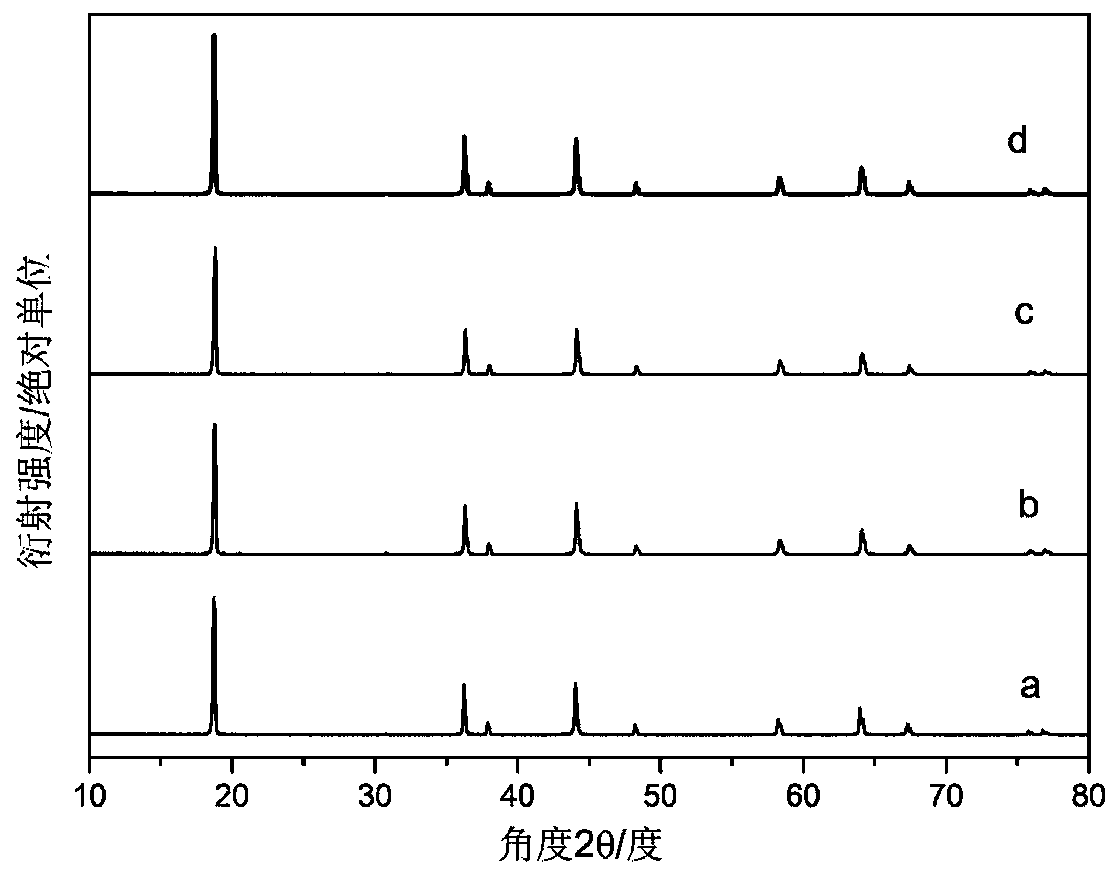

Embodiment 1

[0049] According to Li 2 MnO 3 Weigh 0.3463g of anhydrous lithium acetate and 0.6305g of manganese acetate, add deionized water to make 100mL solution, add 10g of spinel lithium manganate to the above mixed solution in a water bath at 80°C at 600 rpm Stir evenly and dry; the obtained product is calcined at 700° C. for 6 hours, ground and sieved to obtain a composite material.

[0050] The charging and discharging performance tests of the composite materials obtained in the following examples and comparative examples are carried out according to the following method: mix the obtained composite materials, acetylene black, and PVDF in a mass ratio of 8:1:1, add NMP and grind them into a uniform slurry Then coated on aluminum foil, dried at 120°C for 12h, with metal lithium sheet as the negative electrode, 1M LiPF 6 A CR2023 button cell was made for the electrolyte. The electrochemical performance test voltage is 3-4.3V, 0.2C (1C=148mAh / g) cycle for 2 cycles and then 1C cycle, ...

Embodiment 2

[0052] Weigh 10g of spinel-type lithium manganate and 0.5g of polyvinylpyrrolidone, add deionized water and sonicate for 2 hours; place the sonicated solution in a water bath at 80°C at 600 rpm and continue to stir; according to 0.5Li 2 MnO 3 0.5LiMn 0.5 Ni 0.5 o 2 Weigh 0.2963g of anhydrous lithium acetate, 0.5241g of manganese acetate, and 0.1774g of nickel acetate into the above-mentioned continuously stirring solution, and dry; the obtained product is calcined at 750°C for 6h, ground and sieved to obtain a composite material.

[0053] The electrochemical test method of the composite material obtained in this embodiment is the same as that in embodiment 1.

Embodiment 3

[0055] Weigh 10g of spinel lithium manganate and 0.5g of polyvinylpyrrolidone, add deionized water and sonicate for 1h; place the sonicated solution in a water bath at 80°C at 600 rpm and continue to stir; according to 0.5Li 2 MnO 3 0.5LiMn 0.5 Ni 0.5 o 2 Weigh 0.2963g of anhydrous lithium acetate, 0.5241g of manganese acetate, and 0.1774g of nickel acetate into the above-mentioned continuously stirring solution, and dry; the obtained product is calcined at 850°C for 6h, ground and sieved to obtain a composite material.

[0056] The electrochemical test method of the composite material obtained in this embodiment is the same as that in embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com