Desulfurization waste water recycling device

A technology for desulfurization wastewater and wastewater pools, which is applied in water conservancy projects, gaseous effluent wastewater treatment, transportation and packaging, etc. It can solve the problems of sprinkler head blockage, secondary pollution, high salt content, etc., and achieve reduced water replenishment and operation Convenience and water saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

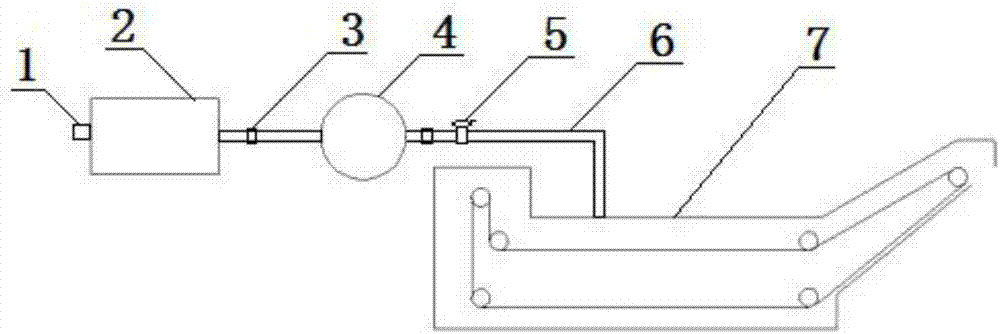

[0018] A desulfurization waste water recycling device, such as figure 1 As shown, it includes waste water tank 2, pipeline 6, flange 3, valve 5, water pump 4 and slag removal machine 7, waste water tank 2, water pump 4 and slag removal machine 7 are connected through pipeline 6 in turn, and pipeline 6 is connected through flange 3 , by using flanges to connect the pipelines 6, it is easy to disassemble when the pipelines 6 need to be overhauled or replaced. The pipelines 6 are provided with valves 5, and the amount of water passing through the pipelines 6 is controlled by the valves 5. The waste water pool 2 is provided with a water inlet.

[0019] Before all the desulfurization wastewater is introduced into the zero-overflow wet slag discharge system, the amount of desulfurization wastewater must be less than or equal to the sum of the water taken away by boiler radiation evaporation and the water taken away by wet slag discharge, and the wet slag discharge water treatment sy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com