Preparation method of modified polyurethane-organosilicon double layer pervaporation membrane

A technology of pervaporation membrane and polyurethane membrane, applied in the field of pervaporation dephenolization membrane and its preparation, can solve problems such as complex process, achieve improved permeability and selectivity, ensure operation stability, strong innovation and application prospect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

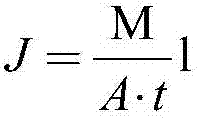

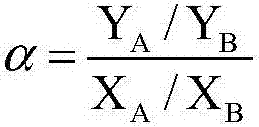

[0018] (1) Preparation of polyurethane film layer. Put the PU particles into the solvent DMAc, and the mass of the PU particles accounts for 10% of the total mass of the solution. After being uniformly dissolved, add DCTB with 0.5% of the mass of the PU, and stir mechanically until dissolved. Cast to form a film, put it into a normal pressure oven and dry it at 80°C for 5 hours, then put it into a vacuum oven and dry it at 80°C for 12 hours. (2) Composite of silicone layer. Add polydimethylsiloxane (PDMS) to the solvent n-heptane, stir magnetically at 30°C for 15 minutes until dissolved, then add tetraethyl orthosilicate (crosslinking agent) and catalyst (dibutyl dilauric acid tin), and continue to stir at 30°C for 10 min until it dissolves and becomes viscous. Then scrape the casting solution on the modified PU film prepared in (1) (one side, the side exposed to the air), let it stand at room temperature for 10 h, then put it in a vacuum drying oven, and dry it at 80 ° C fo...

Embodiment 2

[0020] (1) Preparation of polyurethane film layer. The PU particles are put into the solvent DMAc, and the mass of the PU particles accounts for 10% of the total mass of the solution. After dissolving evenly, DCTB with 1% of the PU mass is added, and mechanically stirred until dissolved. Cast to form a film, put it into a normal pressure oven and dry it at 80°C for 5h, then put it into a vacuum drying oven and dry it at 150°C for 5h. (2) Composite of silicone layer. Add polydimethylsiloxane (PDMS) to the solvent n-heptane, stir magnetically at 30°C for 15 minutes until dissolved, then add tetraethyl orthosilicate (crosslinking agent) and catalyst (dibutyl dilauric acid tin), continue to heat and continue to stir at 30°C for 5 minutes until it dissolves and becomes viscous. Then scrape the casting liquid on the modified PU film prepared in (1) (one side, the side exposed to air), let it stand at room temperature for 10 h, then put it into a vacuum drying oven, and dry it at 1...

Embodiment 3

[0022] (1) Preparation of polyurethane film layer. Put the PU particles into the solvent DMAc, and the mass of the PU particles accounts for 10% of the total mass of the solution. After being uniformly dissolved, add DCTB with 0.5% of the mass of the PU, and stir mechanically until dissolved. Cast to form a film, put it into a normal pressure oven and dry it at 80°C for 5h, then put it into a vacuum drying oven and dry it at 150°C for 5h. (2) Composite of silicone layer. Add polydimethylsiloxane (PDMS) to the solvent n-heptane, stir magnetically at 30°C for 15 minutes until dissolved, then add tetraethyl orthosilicate (crosslinking agent) and catalyst (dibutyl dilauric acid tin), continue to stir at 30°C for 10 min until it dissolves and becomes viscous. Then scrape the casting solution on the modified PU film prepared in (1) (one side, the side exposed to the air), let it stand at room temperature for 10 h, then put it in a vacuum drying oven, and dry it at 80 ° C for 12 h....

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation factor | aaaaa | aaaaa |

| separation factor | aaaaa | aaaaa |

| separation factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com