Production process of imitated silicified wood crystal wood grain powder coating product

A powder coating and production process technology, applied in powder coating, coating, etc., can solve the problems of lack of imitation siliconized wood crystal wood grain decoration materials, high cost, high price, etc., and achieve excellent storage stability, low cost, and applicable good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

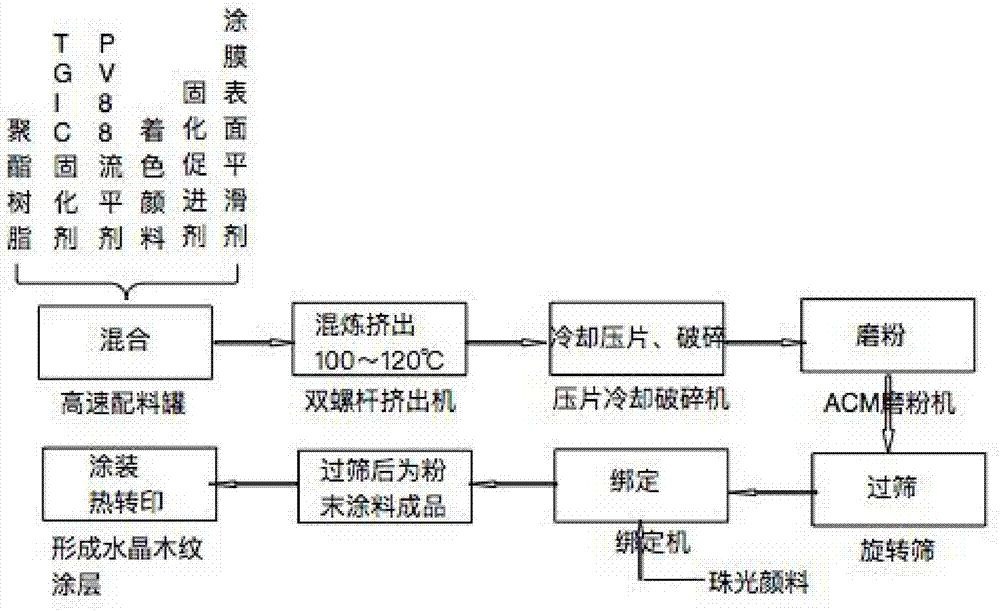

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in combination with specific embodiments.

[0012] A production process for imitating petrified wood crystal wood grain powder coating products, preferably, comprises the following steps, after mixing the raw materials, put them into a high-speed batching tank, put the materials into the high-speed mixing batching tank and mix for 5 minutes, and transfer the mixed materials into The hopper of the twin-screw extruder is hot-kneaded and extruded at a temperature of 100-120 °C, cooled and crushed by a tablet cooling crusher, and then transferred to an ACM mill for grinding and sieving to make a powder with an average particle size of 35 microns , transfer the powder into a binding machine and add pearlescent pigments in the formula for binding, and make powder coating after sieving.

[0013] The ACM mill includes high-speed crushing, air classification, cyclone separation, screening, and ultrafine powder separation an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com