Method and system for producing ethanol through fermentation of industrial tail gas

A technology of industrial tail gas and fermentation method, which is applied in the direction of fermentation, biochemical equipment and methods, bioreactor/fermentation tank combination, etc. It can solve the problems of low ethanol concentration, high COD and BOD content, and cannot be directly discharged, so as to achieve purification Emissions, effects of improving purity and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

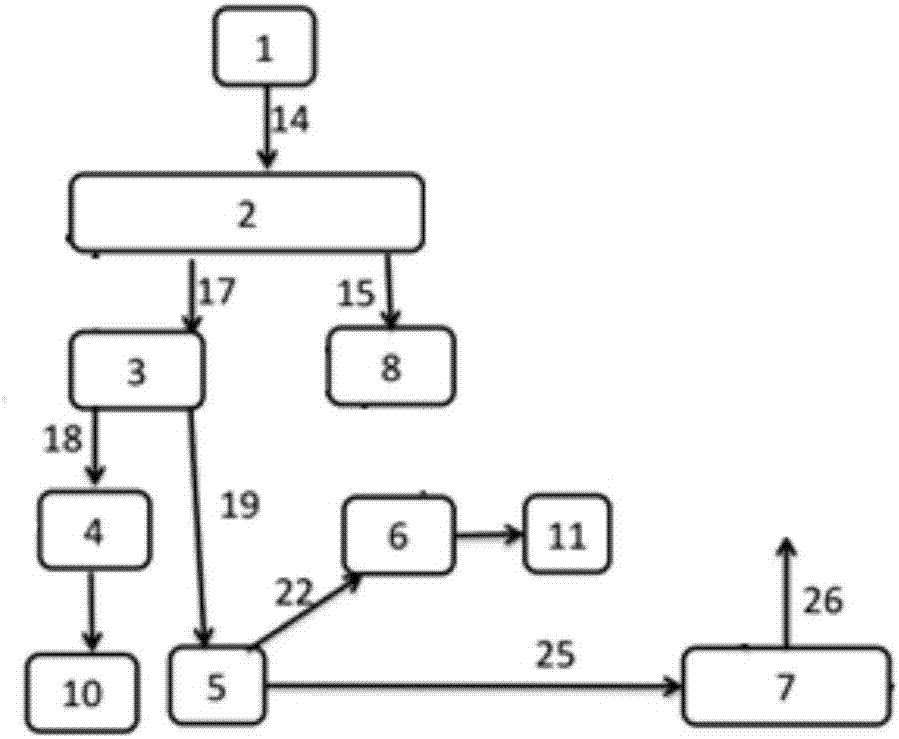

[0057] Such as figure 1 As shown, the system for producing ethanol by industrial tail gas fermentation method in Example 1 of the present invention includes a gas pretreatment device 1, a fermentation device 2, a distillation device 3, a dehydration device 4, a cell protein separation device 5, a drying device 6, and a sewage treatment device 7. Tail gas treatment device 8; the method for preparing ethanol by using the above-mentioned system as raw material with industrial tail gas comprises the following steps:

[0058] The raw material industrial tail gas is pressurized by a compressor in the gas pretreatment system, and then purified industrial tail gas 14 is obtained after desulfurization, deoxidation, and cooling, and sent to the fermentation device 2 . In the fermentation device 2, the bacteria continuously proliferate with industrial tail gas as raw material, and produce ethanol and other chemicals through metabolism. The mature mash 17 with an ethanol concentration of...

Embodiment 2

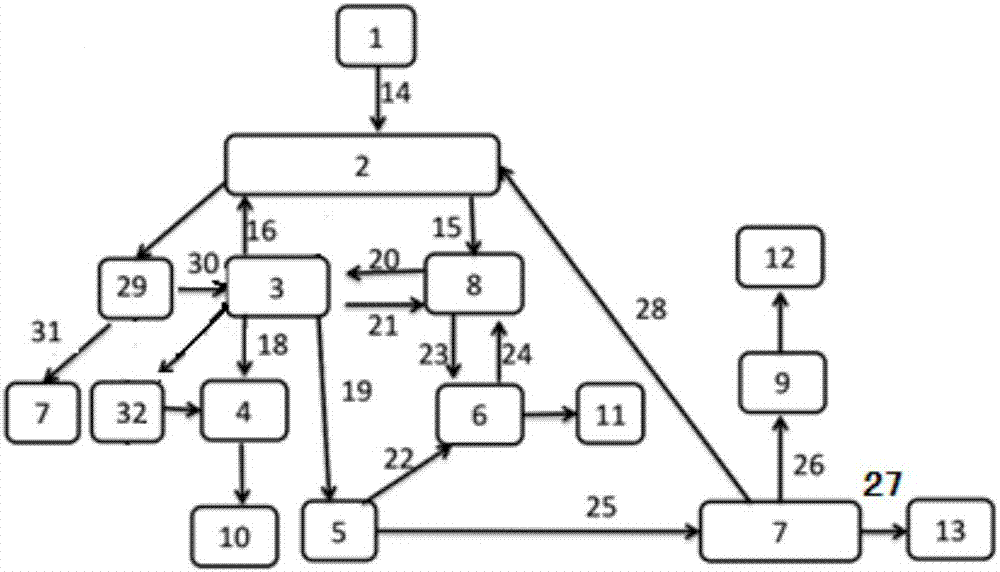

[0065] Such as figure 2 As shown, the system for preparing ethanol from industrial tail gas in Example 2 of the present invention includes a gas pretreatment device 1, a fermentation device 2, a distillation device 3, a dehydration device 4, a cell protein separation device 5, a drying device 6, and a sewage treatment device 7. Tail gas treatment device 8, compressed natural gas CNG device 9 and BDO separation device 29; the method for preparing ethanol by using the above-mentioned system with industrial tail gas as raw material includes the following steps:

[0066] The raw material industrial tail gas is pressurized by a compressor in the gas pretreatment device 1, and then desulfurized, deoxidized, and cooled to obtain a purified industrial tail gas 14, which is sent to the fermentation device 2. In the fermentation device 2, the bacteria continuously proliferate with industrial tail gas as raw material, and produce ethanol and other chemicals through metabolism. The ferm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com