Process for treating acetone-containing and ammonia-containing tail gas produced in production process of triacetoneamine

A production process and technology of triacetone amine, which is applied to the process field containing acetone and ammonia tail gas, can solve problems such as poor applicability, waste, and single technology, and achieve the effects of reducing unit consumption, purifying emissions, and green production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

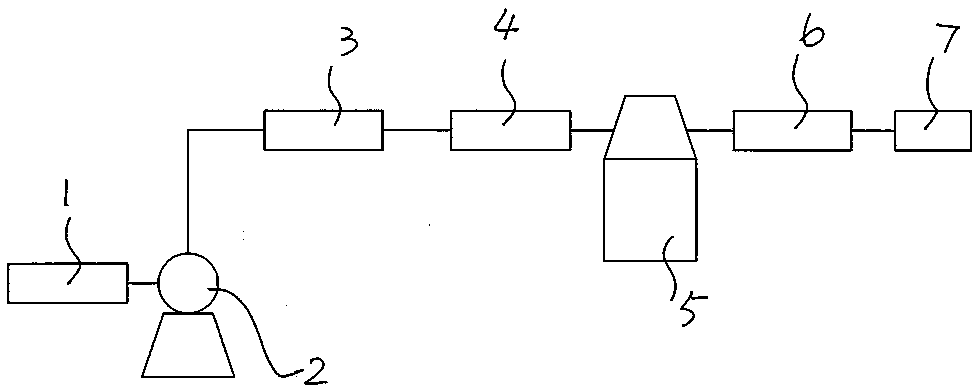

Image

Examples

Embodiment 1

[0028] In the first step, the tail gas containing acetone and ammonia generated during the production of triacetone amine enters the -60 through the pump mechanism o C condenser;

[0029] In the second step, the cryogenically cooled tail gas passes through the air / gas heat exchanger to recover the cooling capacity, and the tail gas can reach 20 o C, non-methane total hydrocarbon concentration 2000 mg / m 3 ;

[0030] In the third step, water is sprayed from the tower and the temperature is controlled at 20 o The top of the packed tower of C enters and contacts with the exhaust gas countercurrently;

[0031] In the fourth step, the tail gas absorbed by water is dehydrated by cooling and drying in ice water, and the water content of the tail gas is less than 0.1%;

[0032] In the fifth step, the tail gas after dehydration is monitored online and the concentration of non-methane total hydrocarbons is 35 mg / m 3 .

Embodiment 2

[0034] In the first step, the tail gas containing acetone and ammonia produced in the production process of triacetone amine enters the -60 o C condenser;

[0035] In the second step, the cryogenically cooled tail gas passes through the air / gas heat exchanger to recover the cooling capacity, and the tail gas can reach 20 o C, non-methane total hydrocarbon concentration 5000mg / m 3 ;

[0036] In the third step, 5% acidic potassium permanganate solution is sprayed from the tower and the temperature is controlled at 60 o C enters from the top of the packed tower and contacts with the tail gas countercurrently;

[0037] In the fourth step, the tail gas absorbed by water is dehydrated by cooling and drying in ice water, and the water content of the tail gas is less than 0.1%;

[0038] In the fifth step, the tail gas after dehydration is monitored online and the concentration of non-methane total hydrocarbons is 50 mg / m 3 .

Embodiment 3

[0040] In the first step, the tail gas containing acetone and ammonia produced in the production process of triacetone amine enters the -60 o C condenser;

[0041] In the second step, the cryogenically cooled tail gas passes through the air / gas heat exchanger to recover the cooling capacity, and the tail gas can reach 20 o C, non-methane total hydrocarbon concentration 4000 mg / m 3 ;

[0042] In the third step, 3% hydrogen peroxide solution is sprayed to control the temperature in the tower at 40 o C enters from the top of the packed tower and contacts with the tail gas countercurrently;

[0043] In the fourth step, the tail gas absorbed by water is dehydrated by cooling and drying in ice water, and the water content of the tail gas is less than 0.1%;

[0044] In the fifth step, the tail gas after dehydration is monitored online and the concentration of non-methane total hydrocarbons is 43 mg / m 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com