Metal powder for powder metallurgy, compound, granulated powder, sintered body

A technology of metal powder and powder metallurgy, which is applied in the field of composites, granulated powder and sintered body, and metal powder for powder metallurgy, which can solve the problems of unavoidable high cost and increased working hours.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

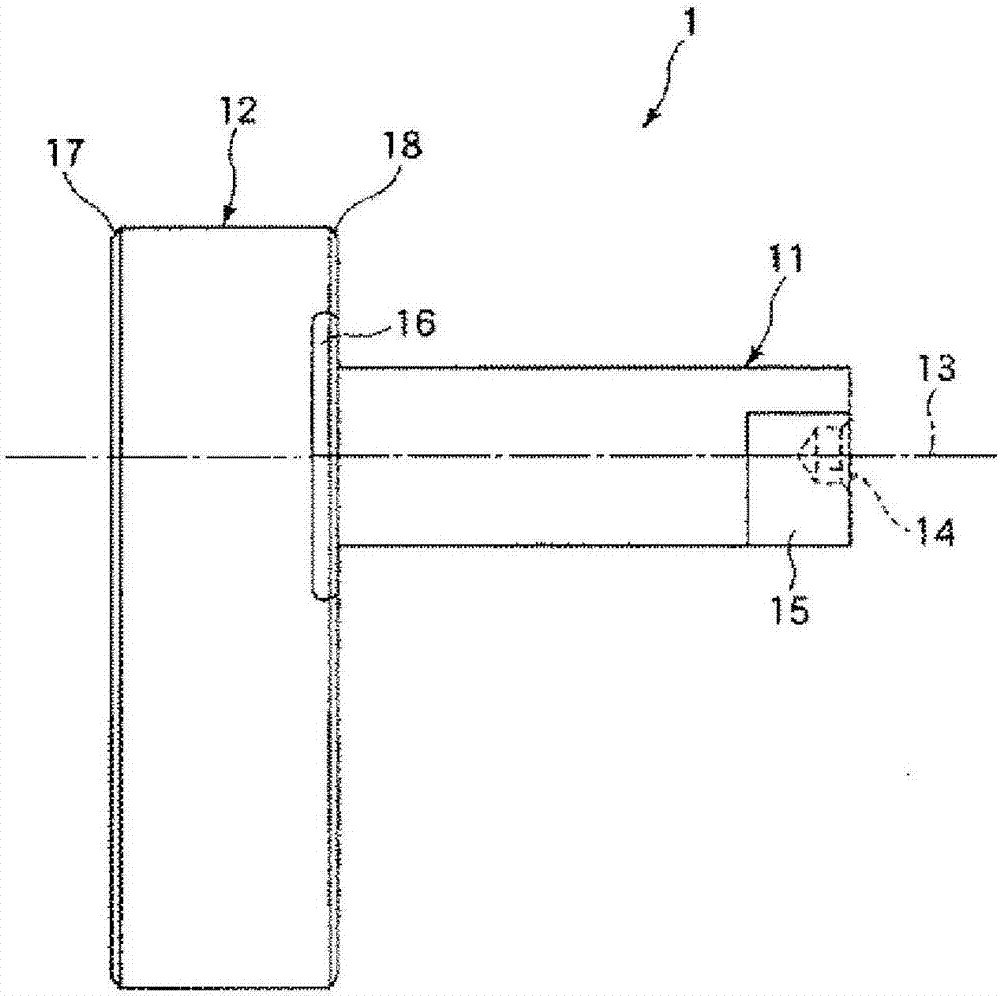

[0226] The heat-resistant member of the present invention can be applied to, for example, a supercharger member. A component for a supercharger to be described later is configured using the first embodiment of the heat-resistant component of the present invention, that is, an embodiment in which at least a part thereof is the sintered body of the present invention.

[0227] Examples of such supercharger components include a nozzle vane for a turbocharger, a turbine wheel for a turbocharger, a wastegate, a turbine housing, and the like. These supercharger components are required to have wear resistance because they are exposed to high temperatures for a long period of time and slide between other components in some cases. As described above, the sintered body of the present invention has excellent heat resistance and mechanical properties due to its high density. Therefore, a component for a supercharger that maintains excellent durability over a long period of time is obtaine...

no. 2 approach

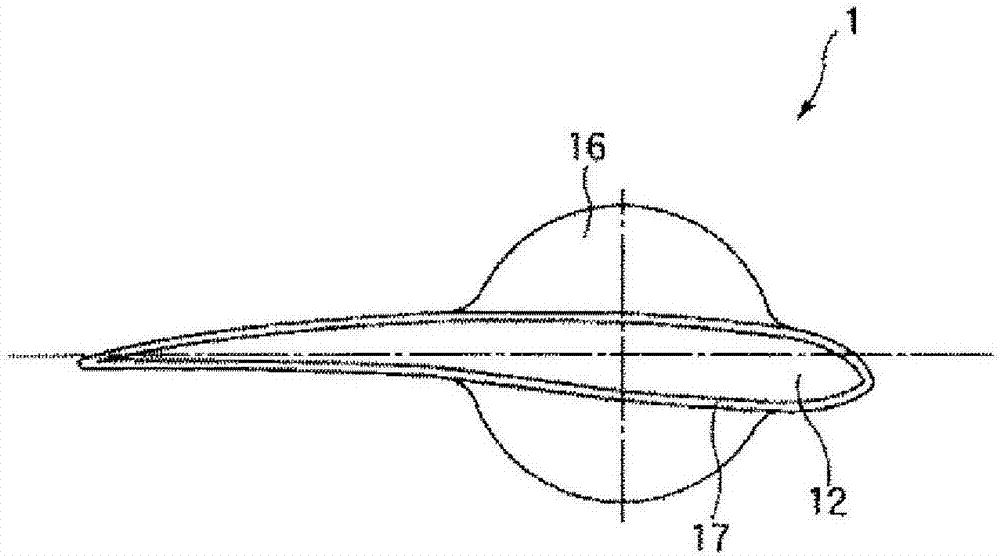

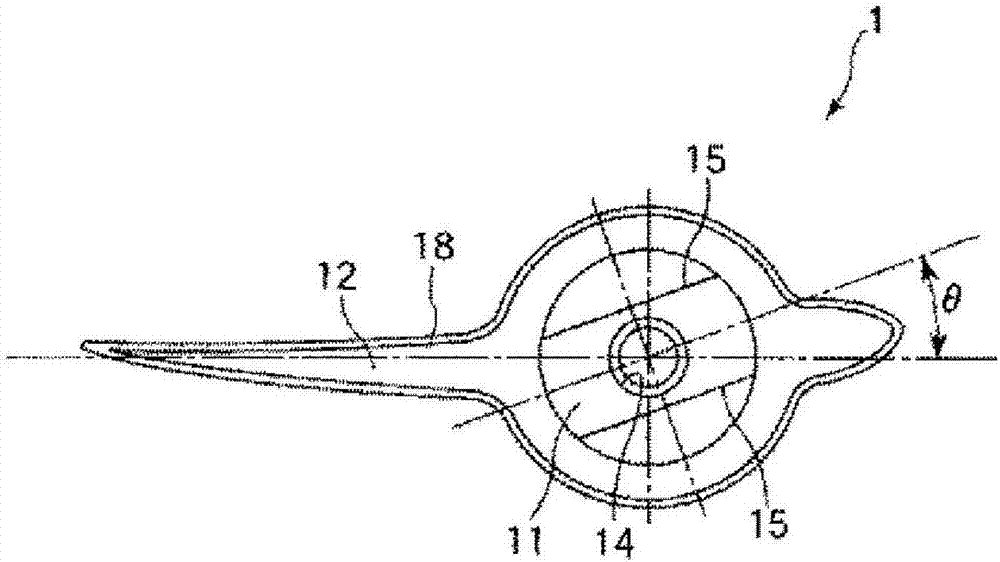

[0242] The heat-resistant member of the present invention can be applied to, for example, a compressor blade as a member for a jet engine or a member for a power generating pulley. Such a compressor blade is constructed using the second embodiment of the heat-resistant component of the present invention, that is, an embodiment in which at least a part thereof is the sintered body of the present invention.

[0243] Figure 4 It is a perspective view which shows the compressor blade to which 2nd Embodiment of the heat-resistant member of this invention was applied. Figure 4 The illustrated compressor blade 2 includes an inner rim 21 and an outer rim 22 arranged concentrically with each other, and wing portions 23 arranged between these rims and arranged along the circumferential direction of the inner rim 21 . The inner rim 21 and the outer rim 22 each form a ring shape. Furthermore, the wing portion 23 is formed in a flat plate shape including a curved surface. Then, the wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com