Composite oil pipe with wear-resisting lining and externally-wrapping heat-insulation and heat-preservation layer

A technology of thermal insulation and composite oil pipes, which is applied in the direction of thermal insulation protection of pipelines, thermal insulation, drilling pipes, etc., can solve the problems of increasing production costs of oil production, wasting electric energy heating furnace heat, large friction resistance of rods and pipes, etc., and reducing oil production. The effect of extraction cost, reduction of pumping unit load, and simplified process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

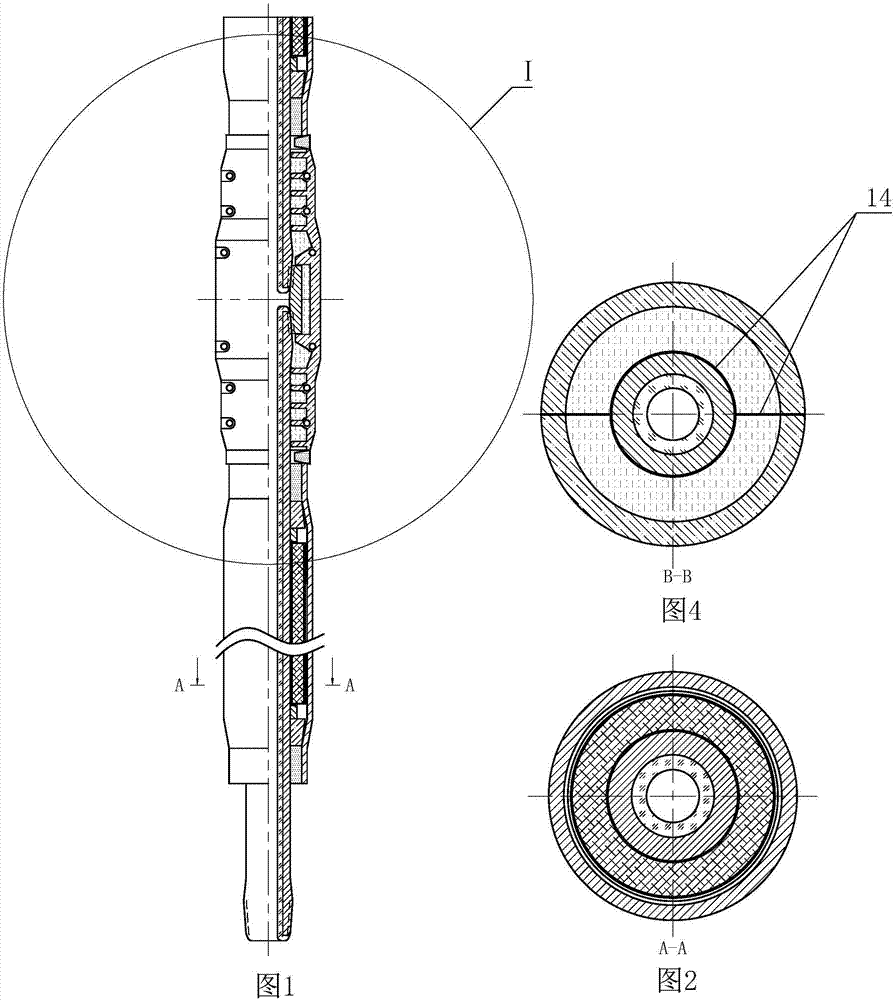

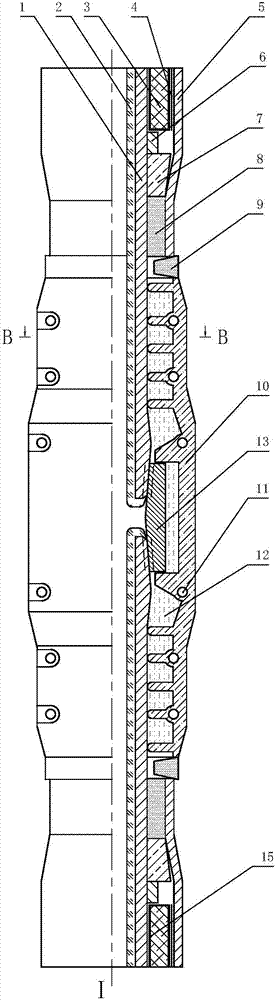

[0020] The structure of a wear-resistant inner lining and outer heat insulation composite oil pipe according to the present invention is as follows: figure 1 , figure 2 , image 3 , Figure 4 Shown: a wear-resistant inner lining, outer wrapped heat insulation oil pipe, the two ends of the oil pipe are threaded sections processed with external threads, the parts close to the threaded sections at both ends are two operating sections, and the part between the two operating sections The part is the middle section, and the oil pipe is connected by the oil pipe coupling between the oil pipe and the oil pipe for downhole use; an inner pipe (2) is fixedly embedded in the oil pipe (1) as the anti-corrosion and wear-resistant layer inside the oil pipe, and the inner pipe (2 ) is longer than the oil pipe (1), and the two end faces of the inner pipe protrude beyond the end face of the oil pipe end; the outer wall of the oil pipe in the middle section of the oil pipe (1) is evenly wrapp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com