Manufacture method of Schottky photovoltaic cell based on graphene and silicon reverse pyramid array

An inverted pyramid, photovoltaic cell technology, applied in the field of solar cells, can solve the problems of light energy loss, inability to effectively utilize incident light energy, etc., and achieve the effects of reducing preparation costs, improving photoelectric conversion efficiency, and small reflection coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

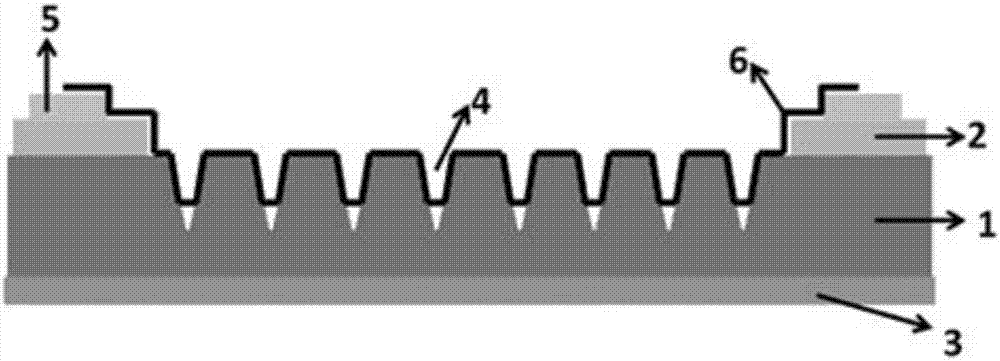

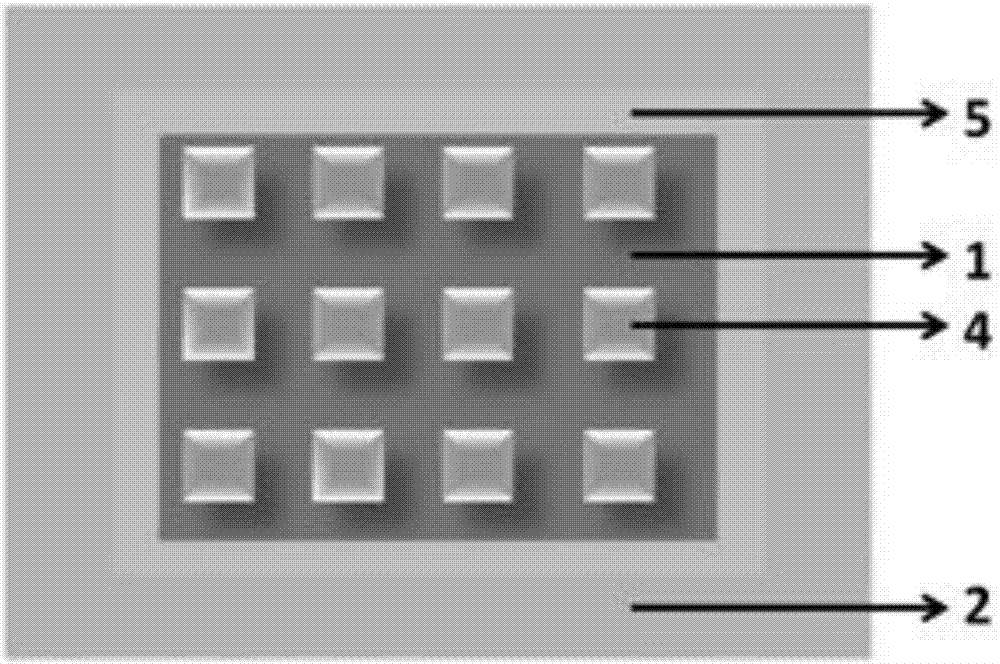

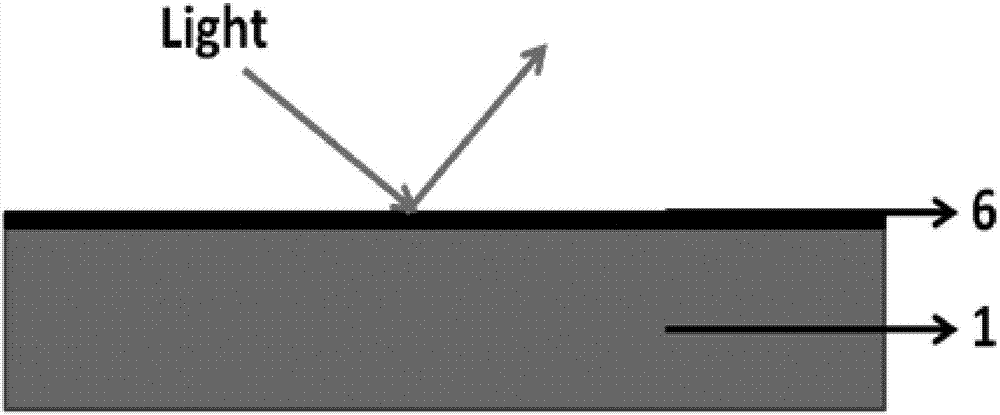

[0032] In this embodiment, when fabricating a graphene-silicon inverted pyramid array Schottky junction photovoltaic cell, first thermally oxidize a single crystal silicon substrate 1 with an n-type (100) resistivity of 1-10 Ω cm, and thermally oxidize and grow SiO with a thickness of 300 nm. 2 as SiO 2 For the isolation layer 2, the oxide layer on the back of the silicon substrate 1 is removed by wet etching, and then the metal In / Ga alloy is applied on the back of the single crystal silicon substrate 1 as the back electrode 3, and SiO is wet etched. 2 The isolation layer 2 forms a window to expose the original silicon surface. The silicon surface is etched by MACE to form a silicon inverted pyramid array 4. The etching time is 15 minutes. The depth of the silicon inverted pyramid hole is about 2 microns, and the diameter is 1 micron. The method of electron beam evaporation prepares the metal front electrode 5 around the isolation layer window, the metal material is Au, and t...

Embodiment 2

[0034] This example makes a graphene silicon inverted pyramid array Schottky photovoltaic cell, similar to Example 1, the difference is that cyclododecane is used to transfer graphene, the process of transferring graphene is simpler, the surface is cleaner, and the prepared device The photoelectric conversion efficiency is 3.50%.

Embodiment 3

[0036] This example makes a graphene silicon inverted pyramid array Schottky photovoltaic cell, similar to Example 1, the difference is that the graphene transparent electrode is p-doped with nitric acid to improve the work function and conductivity of graphene, and then transfer and prepare The photoelectric conversion efficiency of the prepared device is 5.63%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| crystal orientation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com