A kind of method that glucose and castor oil mixture prepares aqueous polyurethane film former

A water-based polyurethane, castor oil technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of generating three wastes, high cost of polyols, large energy consumption, etc., and achieves simple implementation, improved water resistance, and high profits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Prepare a mixture of glucose and castor oil as follows to prepare water-based polyurethane:

[0013] First prepare the mixture of glucose and castor oil, first dissolve 25g of glucose in 200ml of absolute ethanol, stir to make it fully dissolved, slowly add it dropwise to 300ml of castor oil for esterification reaction, react at 85°C for 2h, adjust glucose and castor oil The molar ratio of sesame oil is 0.8:5; after the reaction, vacuumize with a rotary evaporator to remove anhydrous ethanol, and vacuum-dry at 35°C to obtain a mixture of carboxyl-containing glucose and castor oil. Then dissolve 20g of 2,4-toluene diisocyanate (TDI) in 100ml of cyclohexanone, heat the oil bath to 80°C and stir it with a magnetic force, add the mixture of glucose and castor oil, TDI in the ratio of 1:3, dropwise add The total mass of the catalyst is about 0.02%, and the reaction is continued under nitrogen protection; 1% acetic acid is added, and the reaction is continued for 1.5h; the te...

Embodiment 2

[0021] Prepare a mixture of glucose and castor oil as follows to prepare water-based polyurethane:

[0022] First prepare the mixture of glucose and castor oil, first dissolve 30g of glucose in 200ml of absolute ethanol, stir to make it fully dissolved, slowly add it dropwise to 400ml of castor oil for esterification reaction, react at 85°C for 2h, adjust glucose and castor oil The molar ratio of sesame oil is 1:5; after the reaction, vacuumize with a rotary evaporator to remove absolute ethanol, and then vacuum-dry at 35°C to obtain a mixture of carboxyl-containing glucose and castor oil. Then dissolve 15g of 2,4-toluene diisocyanate (TDI) in 100ml of cyclohexanone, heat the oil bath to 80°C and stir it with a magnetic force, add the mixture of glucose and castor oil and TDI in the ratio of 2:3, add the The total mass of the catalyst is about 0.03%, and the reaction is continued under nitrogen protection; 1% acetic acid is added, and the reaction is continued for 2 hours; the...

Embodiment 3

[0030] Prepare a mixture of glucose and castor oil as follows to prepare water-based polyurethane:

[0031] First prepare the mixture of glucose and castor oil, first dissolve 20g of glucose in 200ml of absolute ethanol, stir to make it fully dissolved, slowly add it dropwise to 400ml of castor oil for esterification reaction, react at 85°C for 2h, adjust glucose and castor oil The molar ratio of sesame oil is 2:5; after the reaction, vacuumize with a rotary evaporator to remove anhydrous ethanol, and vacuum-dry at 35°C to obtain a mixture of carboxyl-containing glucose and castor oil. Then dissolve 40g of 2,4-toluene diisocyanate (TDI) in 100ml of cyclohexanone, heat the oil bath to 80°C and stir it with a magnetic force, add the mixture of glucose and castor oil and TDI in a ratio of 1:3, add the The total mass of the catalyst is about 0.02%, and the reaction is continued under nitrogen protection; 1% acetic acid is added, and the reaction is continued for 1.5h; the temperat...

PUM

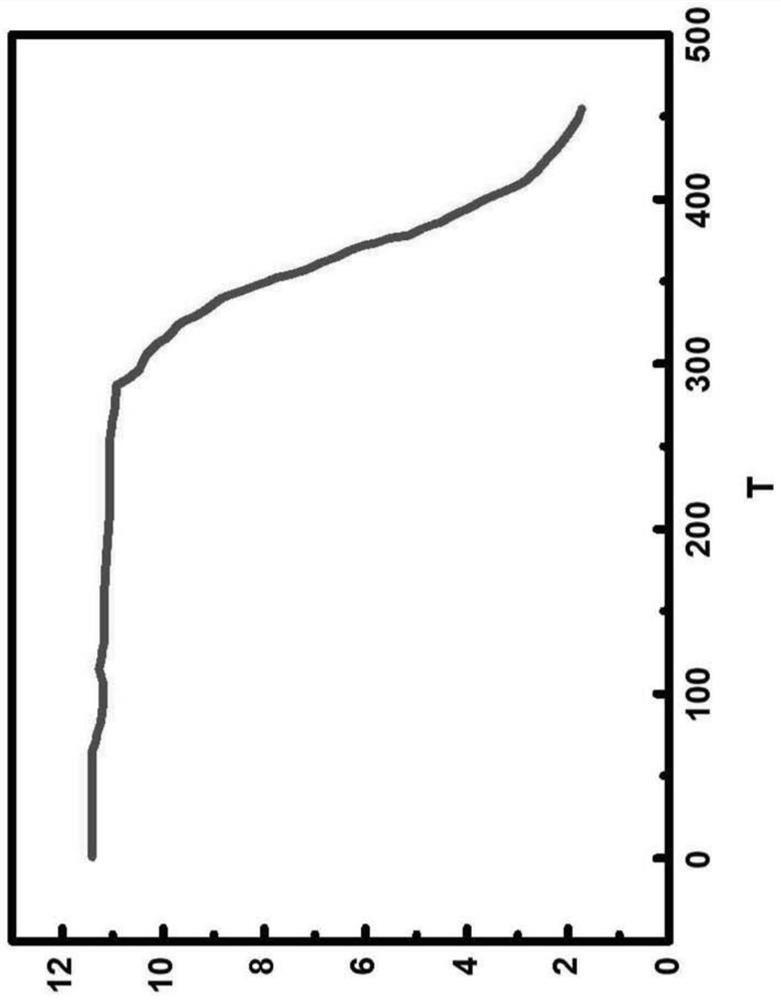

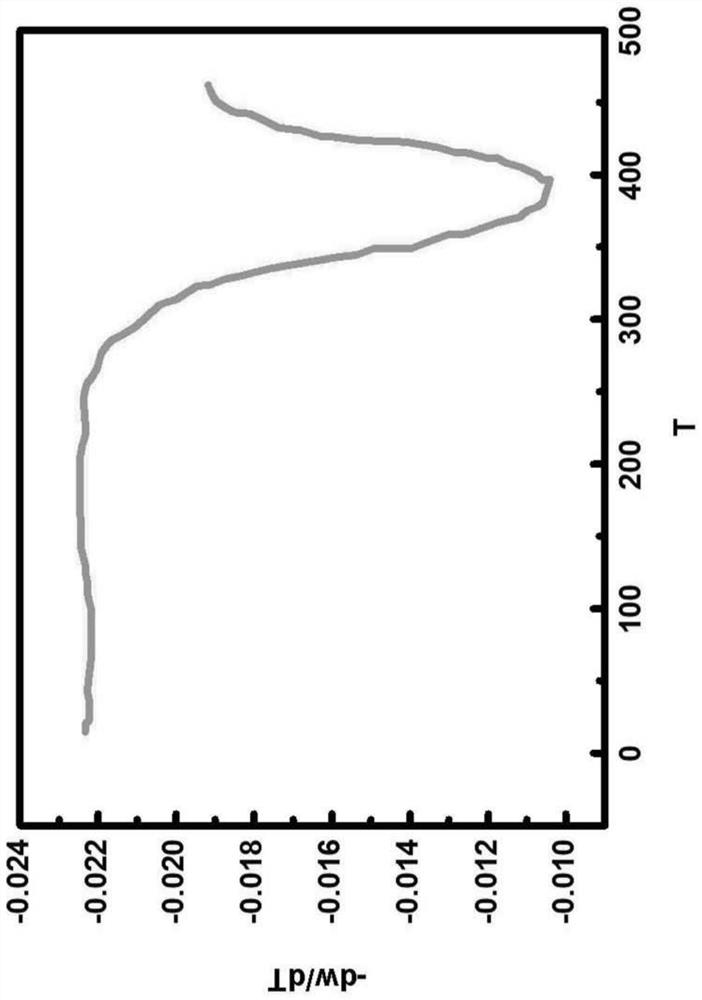

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com