Single white light polymer and organic light-emitting material, and organic light-emitting device and preparation method of organic light-emitting device

A polymer and luminescent technology, applied in the direction of luminescent materials, electrical solid devices, chemical instruments and methods, etc., can solve immature problems, achieve simple preparation procedures, improve device efficiency, and reduce triplet exciton quenching Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

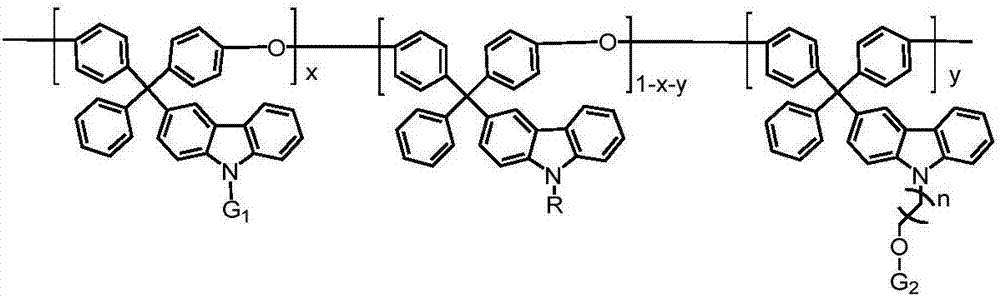

[0064] A single white light polymer (SWPB0.2R0.05) provided in this embodiment has a structural formula as shown below.

[0065]

[0066] The embodiment of the present invention also provides a method for preparing the above-mentioned single white photopolymer (SWPB0.2R0.05):

[0067] S1: Under the protection of nitrogen gas, add carbazole (10.0g, 59.8mmol) and sodium hydride (1.72g, 72.0mmol) to dry dimethylformamide, stir at room temperature for 30 minutes, then add 4,4'- Difluorophenylsulfoxide (15.2g, 60mmol) was stirred for 3h, the solvent was removed, and the residue was washed with deionized water and ethanol to obtain intermediate product 1 (18.2g, yield 76%). The intermediate product 1 is identified and analyzed by a mass spectrometer, and the result is: mass spectrum (EI): m / z C 24 h 16 FNO 2 S theoretical value: 401.4; measured value: 401(M) + , which proves that the intermediate product 1 is C 24 h 16 FNO 2 S.

[0068] S2: Under nitrogen protection, add ...

Embodiment 2

[0088] A single white light polymer (SWPB0.3R0.05) provided in this embodiment has a structural formula as shown below.

[0089]

[0090]This embodiment also provides a method for preparing the above-mentioned single white photopolymer (SWPB0.3R0.05), the operation of which is the same as the preparation method provided in Example 1, and only the operating conditions are changed.

[0091] When preparing intermediate product 1, the molar ratio of carbazole to sodium hydride and 4,4'-difluorophenyl sulfoxide was 1:1:1, and the stirring time was 28 minutes and 3.2 hours, respectively.

[0092] When preparing intermediate product 2, the molar ratio of 3,6-di-tert-butylcarbazole and sodium hydride to intermediate product 1 is 1:1.1:1. The stirring time was 32 minutes.

[0093] When preparing intermediate product 3, the molar ratio of 5,10-dihydrophenazine and palladium acetate is 9:1, and the consumption of degassed toluene is 18mL, K 2 CO 3 The consumption amount of the aque...

Embodiment 3

[0111] A single white photopolymer (SWPV0.4R0.1) provided in this embodiment has a structural formula as shown below.

[0112]

[0113] This embodiment also provides an organic electroluminescent material, which is mainly prepared from the single white photopolymer (SWPV0.4R0.1) in this embodiment and the single white photopolymer (SWPB0.3R0.05) in Example 2.

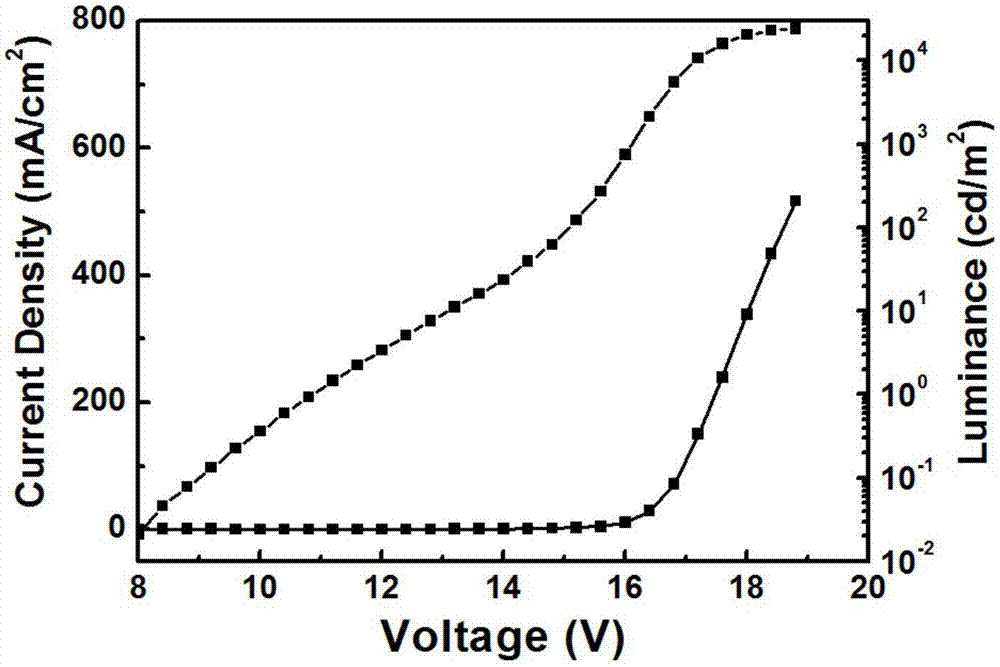

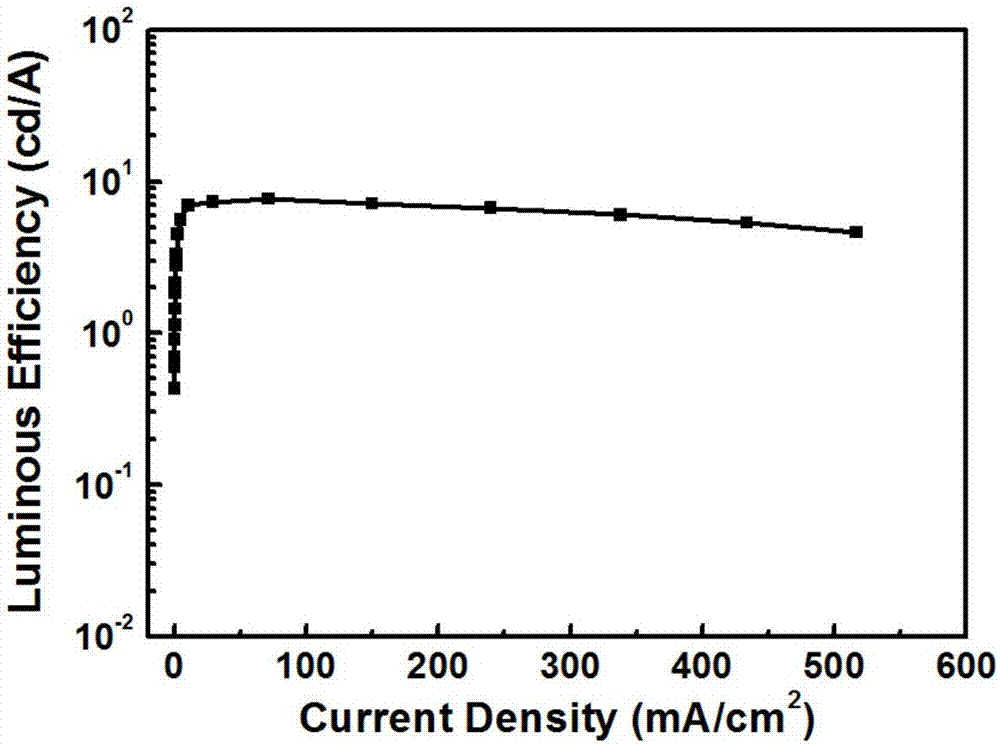

[0114] This embodiment also provides an organic electroluminescent device, the light emitting layer of which is mainly prepared from the above electroluminescent material. Specifically, its structure is ITO / PEDOT:PSS(40nm) / SWPV0.4R0.1, SWPB0.3R0.05(60nm) / TPBi(20nm) / Ca(10nm) / Al(100nm).

[0115] This embodiment also provides a method for preparing an organic electroluminescence device, the preparation method is the same as the preparation method provided in Example 1, the only difference is that the operating conditions are changed.

[0116] The mass concentration of the organic electroluminescent material in the chlo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brightness | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com