Environment-friendly micro-cutting fluid and preparation method thereof

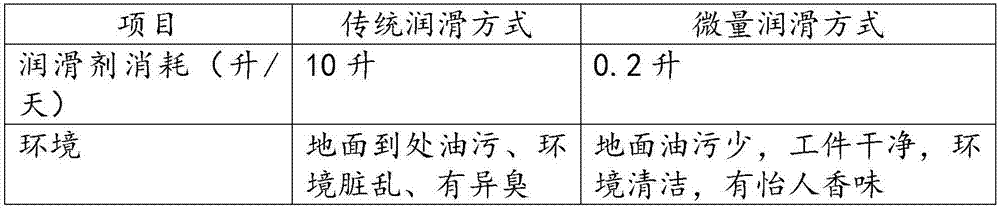

A cutting fluid and environment-friendly technology, applied in the field of environment-friendly micro-cutting fluid and its preparation, can solve the problems of large fluid usage, wasteful leakage, etc., and achieve excellent lubricity, keep the environment fresh, and have remarkable environmental protection effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

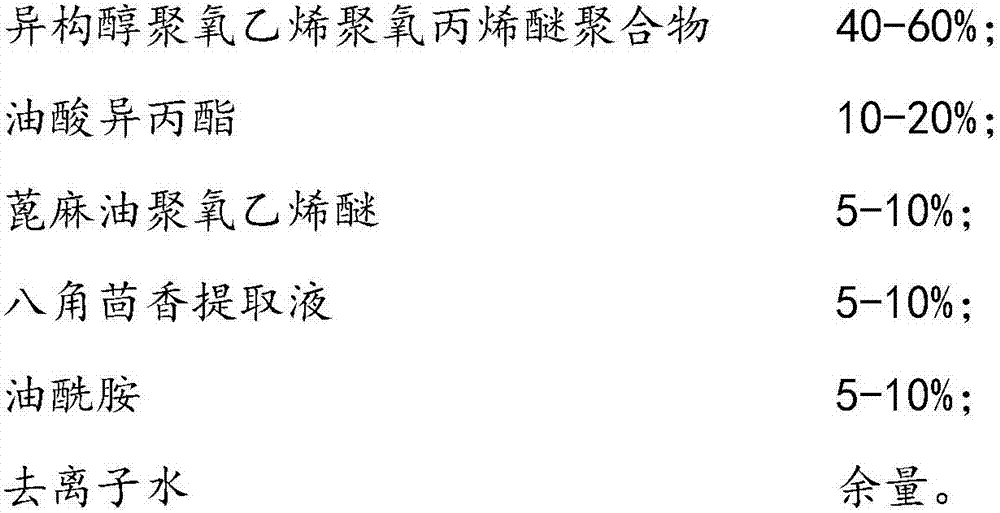

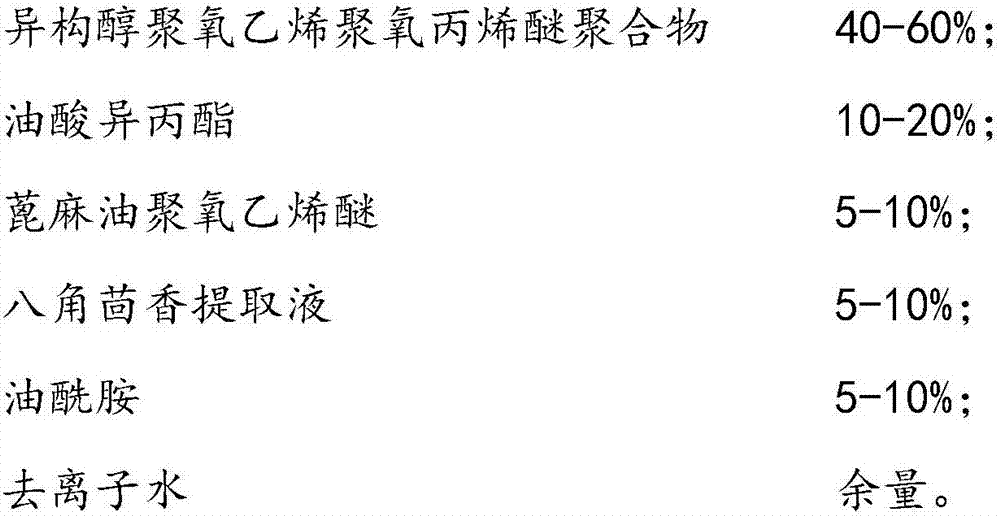

[0033] Add 600g of isomeric alcohol polyoxyethylene polyoxypropylene ether polymer, 100g of isopropyl oleate, 100g of castor oil polyoxyethylene ether (EL-12), 50g of oleamide, and 50g of star anise extract into 100g of deionized water and stir Until the solution is completely transparent or translucent; it is an environmentally friendly micro cutting fluid mother solution.

[0034] The preparation method of the above isomerized alcohol polyoxyethylene polyoxypropylene ether polymer is as follows: 1000g of ISALCHEM145 isomerized alcohol (produced by Sasol Company, the main component is C14 / 15 isomerized alcohol, containing a small amount of C13 and below, C16 and above isomers Alcohol), 150g of potassium hydroxide solution (concentration 20%) was added into the polymerization kettle, cooled with ice-salt water circulation at about 0°C, and at the same time, nitrogen gas was passed into the polymerization kettle to replace the air in the kettle. When the nitrogen in the kettle m...

Embodiment 2

[0039] Add 400g of isomeric alcohol polyoxyethylene polyoxypropylene ether polymer, 200g of isopropyl oleate, 100g of castor oil polyoxyethylene ether (EL-10), 100g of oleamide, and 100g of star anise extract into 100g of deionized water and stir Until the solution is completely transparent or translucent; it is an environmentally friendly micro cutting fluid mother solution.

[0040] The preparation method of the above-mentioned isomerized alcohol polyoxyethylene polyoxypropylene ether polymer is:

[0041] Add 1000g SynativeALG16 isomeric alcohol (manufactured by BASF, the main component is C16 isomeric alcohol), 150g sodium hydroxide solution (concentration 10%) into the polymerization kettle, and circulate and cool with ice-salt water at about 0°C. Enter nitrogen to replace the air in the kettle. When the nitrogen in the kettle maintains a positive pressure, feed 1500g of ethylene oxide and 500g of propylene oxide mixture into the kettle with nitrogen feed tank, and stir at...

Embodiment 3

[0044] Add 500g of isomeric alcohol polyoxyethylene polyoxypropylene ether polymer, 150g of isopropyl oleate, 70g of castor oil polyoxyethylene ether (EL-20), 80g of oleamide, and 80g of star anise extract into 120g of deionized water and stir Until the solution is completely transparent or translucent; it is an environmentally friendly micro cutting fluid mother solution. It can be directly used as a micro-quantity cutting fluid in a micro-quantity lubrication device.

[0045] The preparation method of above-mentioned isomerized alcohol polyoxyethylene polyoxypropylene ether polymer:

[0046]Add 1000g of SAFOL23 isomeric alcohol (produced by Sasol Company, the main component is C12 / C13 isomeric alcohol, containing a small amount of C11 and C14 isomeric alcohol), 120g potassium hydroxide solution (concentration 15%) in the polymerization kettle, and use 0 ℃ The left and right ice salt water is circulated and cooled, and at the same time, nitrogen is introduced into the polyme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com