No-crack photonic crystal having low angle dependence in color generation, and preparation method thereof

A photonic crystal, dependent technology, used in optics, optical components, instruments, etc., can solve the problems of dim color, reduce the effective refractive index of photonic crystals, and affect optical performance, and achieve the effect of eliminating tensile stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

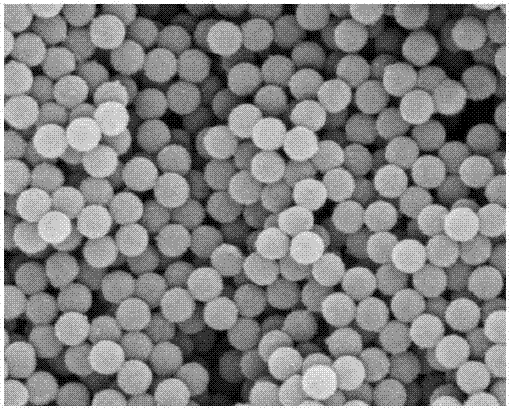

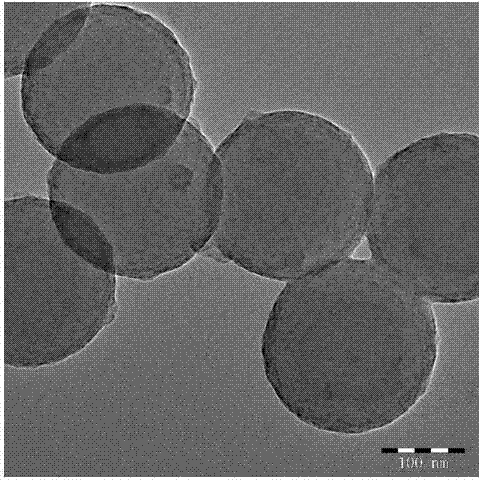

[0032] (1) The polystyrene emulsion with an average particle size of microspheres of 200 nm and good monodispersity was synthesized by soap-free emulsion polymerization. The dispersion index of the polymer in the emulsion was 0.018; the prepared polystyrene emulsion was prepared at 4000 Centrifuge at r / min for 30 min, pour off the supernatant, dry in a vacuum oven at 50°C, and grind to obtain polystyrene microsphere powder;

[0033] (2) Prepare 50ml of tris-hydrochloric acid buffer solution (pH = 8.3) with a concentration of 10 mmol / L; add 0.05g of polystyrene microsphere powder into the buffer solution, and ultrasonically disperse it for 15 minutes. Immediately add 0.025g of dopamine hydrochloride, and stir magnetically for 20 h at room temperature to prepare a polystyrene@polydopamine core-shell microsphere emulsion; Centrifuge for 30 minutes, pour off the supernatant, dry in a vacuum oven at 50°C, and grind to obtain polystyrene@polydopamine microsphere powder;

[0034] Th...

Embodiment 2

[0040] (1) A polystyrene emulsion with an average particle size of microspheres of 220 nm and good monodispersity was synthesized by soap-free emulsion polymerization. The dispersion index of the polymer in the emulsion was 0.024; the prepared polystyrene emulsion was prepared at 4000 Centrifuge at r / min for 30 min, pour off the supernatant, dry in a vacuum oven at 50°C, and grind to obtain polystyrene microsphere powder;

[0041] (2) Prepare 50ml of tris-hydrochloric acid buffer solution (pH = 8.5) with a concentration of 10 mmol / L; add 0.1g of polystyrene microsphere powder into the buffer solution, and ultrasonically disperse it for 15 minutes. Immediately add 0.05 g of dopamine hydrochloride, and stir magnetically for 22 h at room temperature to prepare polystyrene@polydopamine core-shell microsphere emulsion; Centrifuge for 30 minutes, pour off the supernatant, dry in a vacuum oven at 50°C, and grind to obtain polystyrene@polydopamine microsphere powder;

[0042] The enl...

Embodiment 3

[0046] (1) A polystyrene emulsion with an average particle size of microspheres of 350 nm and good monodispersity was synthesized by soap-free emulsion polymerization. The dispersion index of the polymer in the emulsion was 0.046; the prepared polystyrene emulsion was prepared at 4000 Centrifuge at r / min for 30 min, pour off the supernatant, dry in a vacuum oven at 50°C, and grind to obtain polystyrene microsphere powder;

[0047] (2) Prepare 50 ml of tris-hydrochloric acid buffer solution (pH = 8.7) with a concentration of 10 mmol / L; add 0.15 g of polystyrene microsphere powder into the above buffer solution, and ultrasonically disperse it for 15 min. Immediately add 0.075 g of dopamine hydrochloride and stir magnetically at room temperature for 24 h to prepare polystyrene@polydopamine core-shell microsphere emulsion; Centrifuge for 30 minutes, pour off the supernatant, dry in a vacuum oven at 50°C, and grind to obtain polystyrene@polydopamine microsphere powder;

[0048] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com