Two-dimensional layered material-based device and preparation method therefor

A two-dimensional layered and device technology, which is applied in the manufacture of electrode components, the manufacture of discharge tubes/lamps, and parts of discharge tubes/lamps, etc., can solve problems such as poor electron emission characteristics and difficult application of micro-nano devices, and achieve The effect of simple device structure and improved field electron emission characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

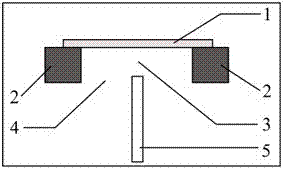

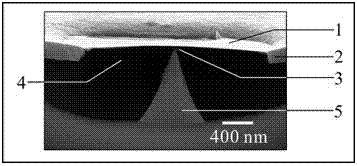

[0045] Such as figure 1 , figure 2 with image 3 (Ix) A device based on a two-dimensional layered material is shown, including electrode one 1 and electrode two 5; the electrode one is a two-dimensional layered material molybdenum disulfide; the electrode one is supported by an auxiliary component 2. , Placed in the air, the auxiliary component 2 is made of chromium material; the auxiliary component 2 is supported by the insulating layer 6; the electrode two 5 is a silicon cone, integrated with the silicon conductive substrate 7, and its top curvature radius It is 1-25 nm, which is specifically 10 nm in this embodiment; the area of the suspended part of the electrode-1 is more than 3 times the area of the tip of the electrode-2, which is specifically 10 in this embodiment. 4 Times; the width of the gap formed between the side of the electrode two 5 and the side of the auxiliary component 2 is 10-5000 nm, specifically 1000 nm in this embodiment; between the electrode one 1 an...

Embodiment 2

[0062] Except that the method for preparing the vacuum electronic device is different, other conditions are the same as in Example 1;

[0063] The vacuum electronic device is prepared by the following method:

[0064] S1. Using a micro-nano processing technology to prepare a silicon tip as electrode two 5 on a silicon conductive substrate 7; the height of the silicon tip is 100-1000nm, and the tip radius of curvature is 1-25nm; in this embodiment, the The height of the silicon cone is specifically 1000 nm, and the radius of curvature of the tip is specifically 10 nm;

[0065] S2. Prepare an insulating layer 6 on the silicon conductive substrate 7 outside the electrode two 5 by using a micro-nano processing technology, and prepare an auxiliary component 2 on the top of the insulating layer 6 to obtain a first combination; the upper surface of the auxiliary component 2 and the electrode The height difference of the top of the second 5 is 1-100 nm; in this embodiment, the height differ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com