Gnaphalium affine extract and preparation method and application thereof

A technology of koji grass and extract, applied in the field of koji grass extract, can solve the problem of low xanthine oxidase inhibitory activity, and achieve the effects of low cost of medicinal materials, huge development potential and abundant wild resources

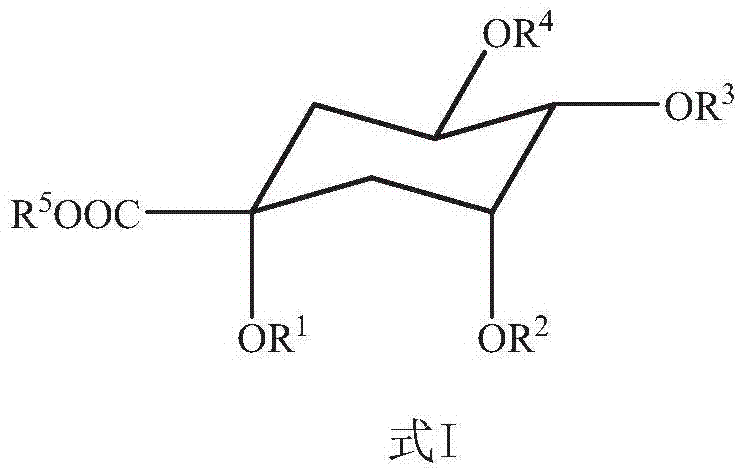

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

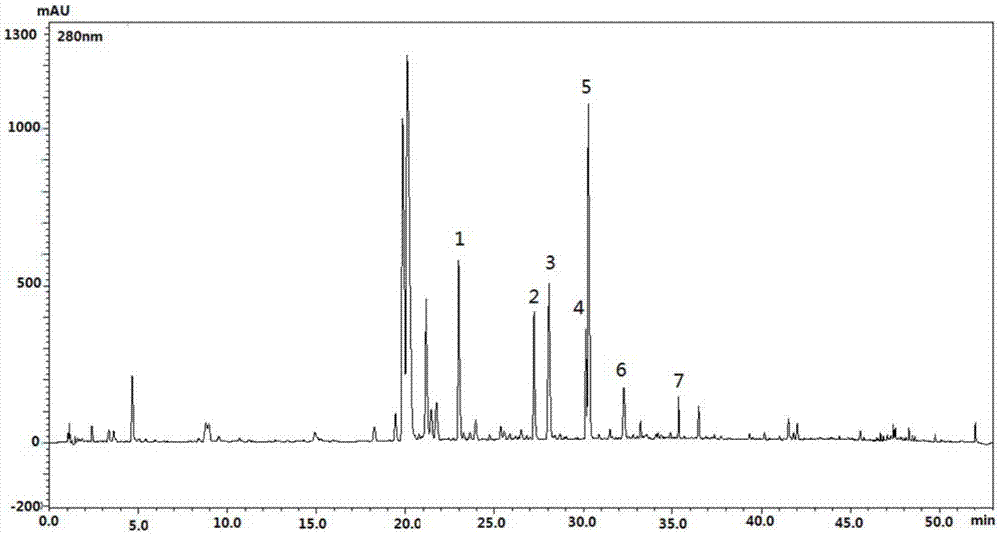

Image

Examples

Embodiment 1

[0031] After drying in the shade, cut Sagegrass into sections, weigh 5kg, mix with 75L (1:15, kg / L) of 60% (v / v) ethanol aqueous solution, heat and reflux for extraction 4 times, each time for 2h, and combine the extracts. The extract was concentrated under reduced pressure (60°C) to 5 L (Sagemus : Concentrate volume 1:1, kg / L) to obtain the extract concentrate.

[0032] Extract the concentrated solution by adding 60-90°C petroleum ether for extraction three times, each time the volume ratio of the concentrated solution to petroleum ether is 1:1 (v / v), discard the petroleum ether phase to obtain the aqueous phase. Ethyl acetate was added to the aqueous phase, and extracted three times, each time the volume ratio of the aqueous phase to ethyl acetate was 1:1 (v / v). After extraction, the ethyl acetate phase was combined, and reduced to dryness to obtain 102.3 g.

[0033] The prepared sage extract (96g) was separated by 200-300 mesh silica gel column chromatography (specificatio...

Embodiment 2

[0046] After drying in the shade, cut Sageweed into sections, weigh 0.6kg, mix with 50% (v / v) ethanol aqueous solution 6L (1:10, kg / L), heat and reflux for extraction three times, each time for 2 hours, and combine the extracts. The extract was concentrated under reduced pressure (60°C) to 1.2L (Sagemusia : Concentrate volume 1:2, kg / L) to obtain the extract concentrate.

[0047] Extract the concentrated solution by adding petroleum ether at 60-90°C to extract twice, each time the volume ratio of the concentrated solution to petroleum ether is 1:2 (v / v), discard the petroleum ether phase, and obtain the aqueous phase. Ethyl acetate was added to the aqueous phase, and extracted twice, each time the volume ratio of the aqueous phase to ethyl acetate was 1:2 (v / v). After extraction, the ethyl acetate phase was combined, and reduced to dryness to obtain 11.7 g.

Embodiment 3

[0049] After drying in the shade, cut Sageweed into sections, weigh 2kg, mix with 40L (1:20, kg / L) of 80% (v / v) ethanol aqueous solution, heat and reflux for extraction twice, each time for 2h, and combine the extracts. The extract was concentrated under reduced pressure (60°C) to 1 L (Sagemus : concentrate volume 1:0.5, kg / L) to obtain the extract concentrate.

[0050] Extract the concentrated solution by adding petroleum ether at 60-90°C to extract 4 times, each time the volume ratio of the concentrated solution to petroleum ether is 1:1 (v / v), discard the petroleum ether phase, and obtain the aqueous phase. Ethyl acetate was added to the aqueous phase, and extracted 4 times, each time the volume ratio of the aqueous phase to ethyl acetate was 1:1 (v / v). After extraction, the ethyl acetate phase was combined, and reduced to dryness to obtain 42.3 g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com