Concentration method of arsenic in arsenic-containing wastewater

A waste water and arsenic precipitation technology, applied in chemical instruments and methods, water pollutants, multi-stage water treatment, etc., can solve problems such as unstable arsenic-containing waste residue, high arsenic concentration requirements, unstable arsenic sulfide residue, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

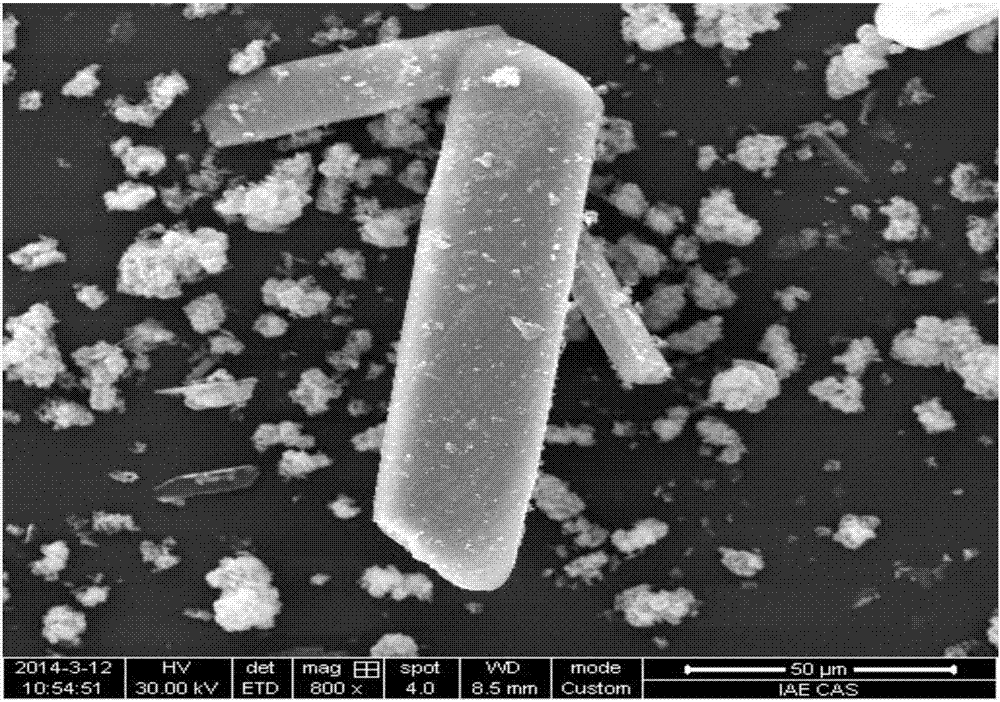

Image

Examples

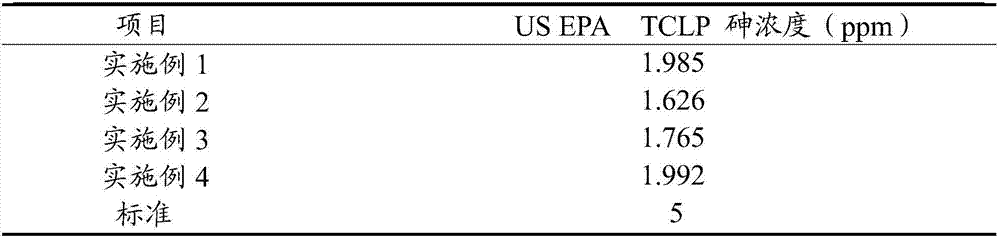

Embodiment 1

[0046] Arsenic-containing wastewater, which contains sulfuric acid 50g / L, As(III): 1.5g / L, at room temperature, use a peristaltic pump to drive into calcium oxide and neutralize the sulfuric acid in it, and separate and remove calcium sulfate precipitation through solid-liquid separation, using a peristaltic pump Add H dropwise to wastewater 2 o 2 , control H 2 o 2 The molar ratio to trivalent arsenic is 1.2. After the oxidation reaction for 1 hour, adjust the pH of the wastewater to 5.0 with calcium oxide, and use a peristaltic pump to add ferrous chloride solution to the arsenic-containing wastewater to control the molar ratio of Fe(II) / As After the dropwise addition, continue to react for 30 minutes, control the pH of the whole reaction process to be 5.0, and obtain a mixed system; separate the solid and liquid of the mixed system to obtain a solid product and a filtrate; return the solid product to a concentrated sulfuric acid solution to control The volume and the mass...

Embodiment 2

[0050] Arsenic-containing wastewater, which contains sulfuric acid 50g / L, As(III): 6.5g / L, at room temperature, use a peristaltic pump to inject calcium oxide and neutralize the sulfuric acid in it, and separate and remove the calcium sulfate precipitate through solid-liquid separation, using a peristaltic pump Add H dropwise to wastewater 2 o 2 , control H 2 o 2 The molar ratio to trivalent arsenic is 1.5. After the oxidation reaction for 1 hour, adjust the pH of the wastewater to 5.5 with calcium oxide, and use a peristaltic pump to feed the ferrous nitrate solution in the arsenic-containing wastewater to control the molar ratio of Fe(II) / As to 1.7. , after the dropwise addition, continue to react for 30 minutes, control the pH of the whole reaction process to be 5.5, and obtain a mixed system; separate the solid and liquid of the mixed system to obtain a solid product and a filtrate; return the solid product to a concentrated sulfuric acid solution to control the volume o...

Embodiment 3

[0053] Arsenic-containing wastewater, which contains sulfuric acid 45g / L, As(III): 20mg / L, at room temperature, use a peristaltic pump to drive into calcium oxide to neutralize the sulfuric acid in it, separate and remove calcium sulfate precipitation through solid-liquid separation, and pour into the remaining liquid Feed oxygen into the phase, control the mol ratio of oxygen and trivalent arsenic to be 1.5, after oxidation reaction 2h, adjust the pH of waste water with sodium hydroxide to be 7, use peristaltic pump to ferrous sulfate solution in the waste water containing arsenic, control Fe( II) The molar ratio of As / As is 3.0:1. After the dropwise addition, continue to react for 1h, control the pH of the whole reaction process to be 6, and obtain a mixed system; separate the solid and liquid of the mixed system to obtain a solid product and a filtrate; Redissolve with concentrated hydrochloric acid solution, control the mass ratio of hydrochloric acid volume and solid produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com