Synthesis method of porous organic covalent framework material having triazine structure

A framework material and synthesis method technology, applied in the synthesis field of organic porous framework materials, can solve the problems of complex experimental process, high cost and high technical requirements, and achieve the effects of simple synthesis process, low synthesis cost and good application prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

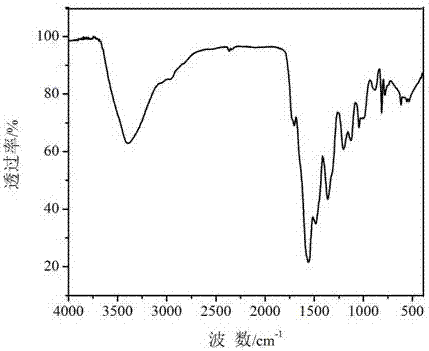

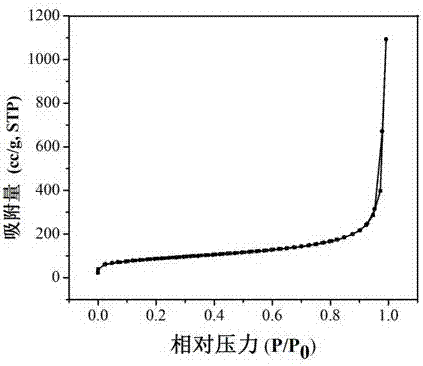

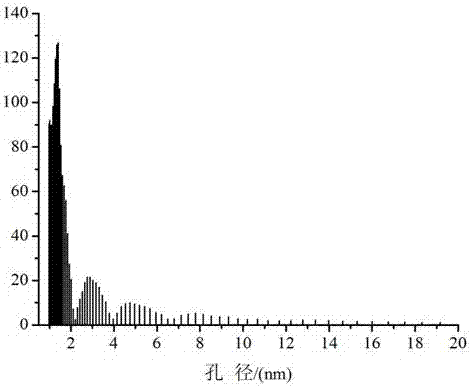

[0026] Dissolve 0.6036g melamine and 0.9225g cyanuric chloride (mass ratio: 1:1) in 20ml of freshly steamed dimethyl sulfoxide (DMSO), then mix the two solutions and place in an oil bath at 150°C Stir the reaction in medium temperature, stop the reaction after four days, and carry out suction filtration after standing and aging overnight (10~12h). Wash with methanol. After washing, vacuum-dry at 60°C for 24 hours, and fully grind to obtain a white powder, which is the product COF product. The yield is about 70%, and the specific surface area of the product is about 301.149 m 2 / g, the pore diameter is about 1.41 nm.

Embodiment 2

[0028] Keeping other conditions constant in Example 1, and increasing the ratio of melamine (the ratio of the amount of substance is 1:1.1), the specific surface area of the product will be reduced, and this is because unreacted melamine is more difficult to obtain from the reaction product Separation in the medium, attached to the surface of the product or its pores, so that the specific surface area is reduced. Therefore, the ratio of the amount of melamine to cyanuric chloride should be strictly controlled at 1:1~1:1.1.

Embodiment 3

[0030] Keeping other conditions unchanged in Example 1, and increasing the reaction temperature to 180° C., it was found that the reaction was completed more rapidly, but as the reaction progressed further, the product would appear yellow and larger particles of precipitates would appear. It has been determined that the specific surface area decreases. This is because the reaction at a higher temperature for a long time will change or even destroy the formed microporous particle structure, which is not conducive to the production of qualified products. Therefore, the reaction temperature should be controlled at 130-150°C.

[0031] In each of the above examples, white gas will be emitted when the reaction is carried out for nearly two hours, and it is recommended to lower the reaction temperature to 130°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com