Intumescent flame retardant polypropylene composite material and preparation method thereof

A technology of flame-retardant polypropylene and intumescent flame retardant, which is applied in the field of flame-retardant polypropylene materials, can solve the problems of damage to the mechanical properties of the base material, narrowing of the application range, poor compatibility of the base material, etc., and achieve improved impact and bending properties , low water solubility, not easy to migrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

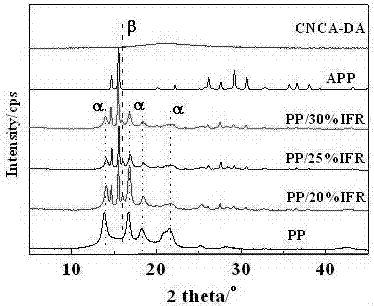

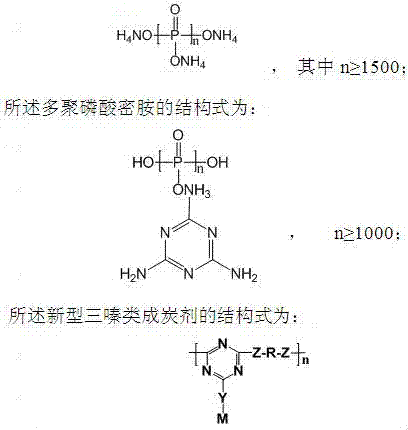

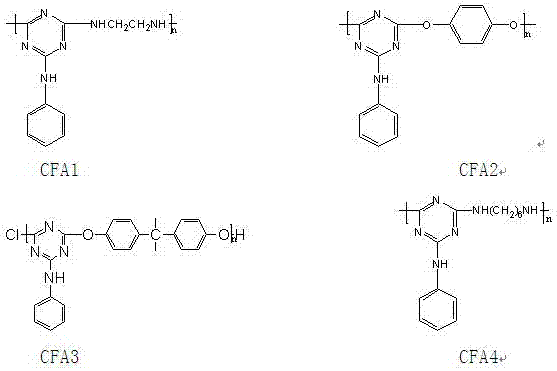

[0024] Add 3.345Kg of polypropylene pellets and 0.15kg of polypropylene wax into the high-speed dispersant and pre-mix for 2 minutes, then accurately weigh 1.0kg of ammonium polyphosphate (APP) and 0.5kg of triazine charcoal agent (CFA1) and 0.005kg of antioxidant (1010) were added to the above mixer and mixed for 15 minutes to obtain an intumescent flame retardant mixture, and finally the obtained intumescent flame retardant mixture was extruded in a twin-screw extruder , cooling, and granulation to obtain intumescent flame-retardant polypropylene composite materials. Wherein, the temperature of each zone of the twin-screw extruder is set between 150-200°C. The oxygen index of the obtained intumescent flame-retardant polypropylene composite material is 35.6%, and the UL-94 test reaches the V-0 level (3.2mm). After adding the carbon forming agent, the composite material formed a certain β crystal, and after the XRD test, there was an obvious β crystal, K β The value is 0.12....

Embodiment 2

[0026] First add 3.39Kg of polypropylene pellets and 0.10k of N,N-ethylene bisstearic acid amide (EBS) into the high-speed mixer and pre-mix for 5 minutes, and then accurately weigh 1.0kg of ammonium polyphosphate ( APP), 0.5kg of triazine char-forming agent (CFA2) and 0.010kg of antioxidant (168), added to a high-speed mixer and pre-mixed for 10 minutes to obtain an intumescent flame retardant mixture, and finally the intumescent flame retardant The mixture is extruded through a twin-screw extruder, cooled and granulated to obtain an expanded flame-retardant polypropylene composite material. Wherein, the temperature of each zone of the twin-screw extruder is between 150-200°C. The oxygen index of the polypropylene composite material is 33.6%, and the UL-94 test reaches the V-0 level. After adding the carbon forming agent, the composite material formed a certain β crystal, and after the XRD test, there was an obvious β crystal, K β The value is 0.08, such as figure 1 shown....

Embodiment 3

[0028] First add 3.44Kg of polypropylene powder and 0.05kg of calcium stearate into the high-speed disperser and pre-mix for 4 minutes; then accurately weigh 0.75kg of ammonium polyphosphate (APP) and 0.75kg of triazine compounds Charcoal (CFA3) and 0.01kg of antioxidant 264 were added to the above-mentioned high-speed mixer and pre-mixed for 8 minutes to obtain an intumescent flame-retardant mixture, which was finally extruded, cooled, and granulated in a twin-screw extruder, namely Intumescent flame retardant polypropylene composites are available. Wherein, the temperature of each zone of the twin-screw extruder is set between 150-200°C. The oxygen index of the polypropylene composite material is 31.1%, and the UL-94 test reaches the V-0 level. After adding the carbon forming agent, the composite material formed a certain β crystal, and after the XRD test, there was an obvious β crystal, K β The value is 0.05, such as figure 1 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com