Nanomaterial compound unsaturated polyester antirust paint and preparation method thereof

A nano-material, unsaturated technology, applied in polyester coatings, anti-corrosion coatings, coatings, etc., can solve the problems of high surface free energy, easy aggregation of nanoparticles, weak bonding, etc., to achieve excellent comprehensive performance of coating films, preparation The effect of simple process and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

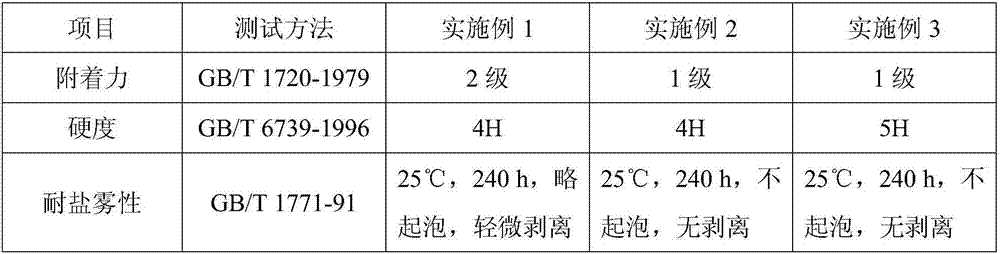

Examples

Embodiment 1

[0038] This embodiment discloses a preparation process of a nanomaterial composite unsaturated polyester antirust paint, which has the following steps in turn:

[0039] (1) Preparation of modified montmorillonite: in parts by mass, add 1 part of nano-montmorillonite (average particle size 50-80 nm) to 100 parts of deionized water, add 1 part of dodecyl after swelling for 24 hours Trimethylammonium bromide, sonicated for 3 hours, centrifuged and dried under 0.05MPa vacuum for 24 hours to obtain modified montmorillonite;

[0040](2) Synthesis of nanomaterial composite polyester resin: in parts by mass, add 28.5 parts of isophthalic acid, 12 parts of polyether glycol, 25 parts of ethylene glycol, and 3 parts of methacrylic acid in a four-necked flask and 0.2 parts of dibutyltin dilaurate, heated to 180°C in an oil bath, and after stirring for 2.5 hours at a stirring rate of 600r / min, add 1.5 parts of the modified montmorillonite prepared in step (1), and heat up to 210°C , and k...

Embodiment 2

[0043] This embodiment discloses a preparation process of a nanomaterial composite unsaturated polyester antirust paint, which has the following steps in turn:

[0044] (1) Preparation of modified montmorillonite: in parts by mass, add 1 part of nano-montmorillonite (average particle size 50-80 nm) to 100 parts of deionized water, add 1.5 parts of dodecyl after swelling for 24 hours Trimethylammonium bromide, sonicated for 3 hours, centrifuged and dried under 0.05MPa vacuum for 24 hours to obtain modified montmorillonite;

[0045] (2) Synthesis of nanomaterial composite polyester resin: in parts by mass, add 30 parts of isophthalic acid, 12 parts of polyether glycol, 24 parts of ethylene glycol, 5 parts of methacrylic acid in a four-necked flask and 0.2 parts of dibutyltin dilaurate, heated to 180°C in an oil bath, kept stirring at a stirring rate of 800r / min for 2.5h, then added 2 parts of modified montmorillonite, raised the temperature to 210°C, and stirred at 1200r / min Ke...

Embodiment 3

[0048] This embodiment discloses a preparation process of a nanomaterial composite unsaturated polyester antirust paint, which has the following steps in turn:

[0049] (1) Preparation of modified montmorillonite: in parts by mass, add 1 part of nano-montmorillonite (average particle size 50-80 nm) to 100 parts of deionized water, add 1.5 parts of dodecyl after swelling for 24 hours Trimethylammonium bromide, sonicated for 3 hours, centrifuged and dried under 0.05MPa vacuum for 24 hours to obtain modified montmorillonite;

[0050] (2) Synthesis of nanomaterial composite polyester resin: in parts by mass, add 32 parts of isophthalic acid, 12 parts of polyether glycol, 24 parts of ethylene glycol, and 3 parts of methacrylic acid in a four-necked flask and 0.3 parts of dibutyltin dilaurate, heated to 180°C in an oil bath, kept stirring at a stirring rate of 900r / min for 2.5h, then added 2.5 parts of modified montmorillonite, raised the temperature to 210°C, and stirred at 1200r / m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com