Fruity high-fiber cereal powder and processing method thereof

A cereal powder, high-fiber technology, applied in food science, function of food ingredients, dairy products, etc., can solve the problems of flavor, decreased effective nutrients, decreased regulation, easy inactivation of probiotics, etc. Glycemic index, good dispersibility, good flavor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

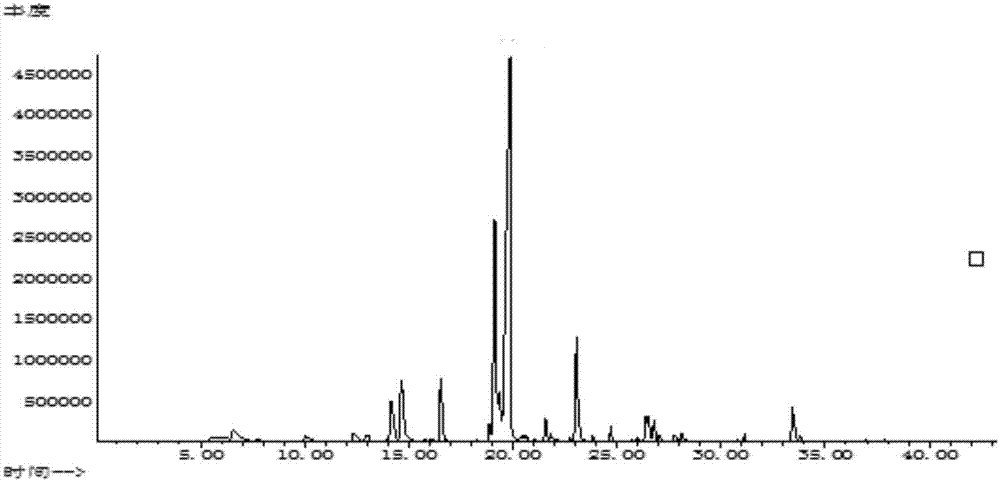

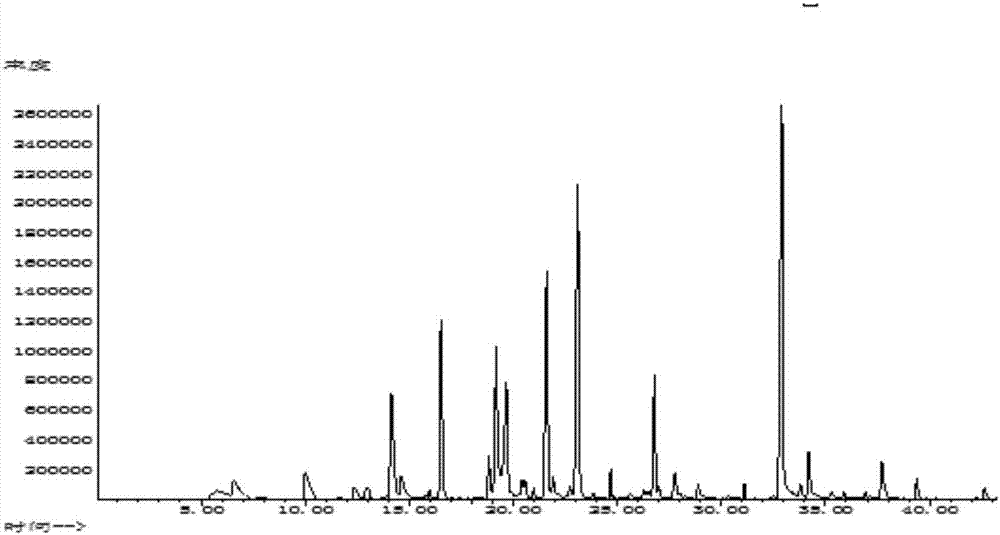

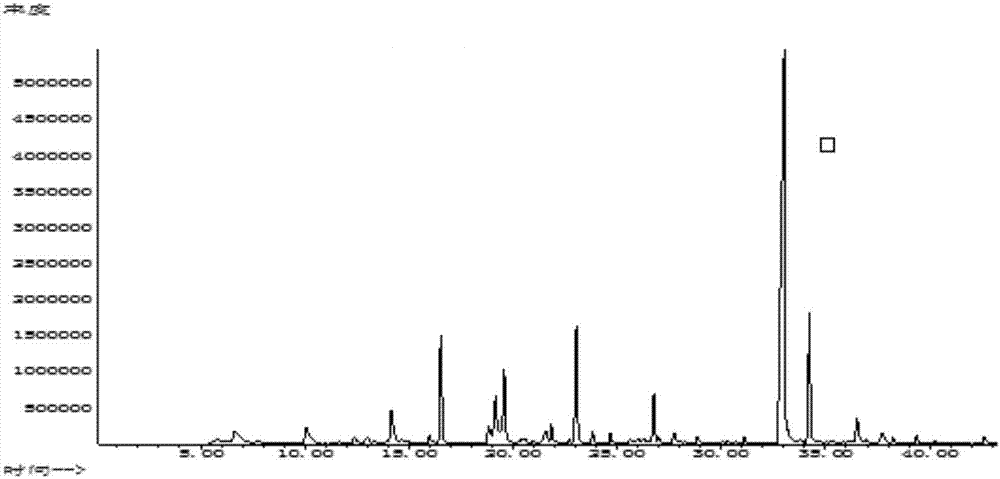

Image

Examples

Embodiment 1

[0041] (1) Cold-pressed juice: select strawberries (3-5) with a suitable sugar-acid ratio for processing, and use a concentration of 0.005g / kg of stable chlorine dioxide to clean the fruit, drain after cleaning, and use a beater to crush and beat the juice. Add 0.75% pectinase to hydrolyze for 45 minutes, filter and set aside;

[0042] (2) Fermented milk: select high-quality milk (protein content > 3.5g / L) for fermentation, use Streptococcus thermophilus: Lactobacillus bulgaricus: Bifidobacterium to ferment at a ratio of 1:1:1, and add 10 5 cfu / g was fermented at 38-42°C until the pH reached 4.0, and the fermentation was stopped for later use;

[0043] (3) Oat processing: crush the oats and pass through a 40-mesh sieve, add 10 times the mass of water, heat at 100°C for 120 minutes, use a three-legged centrifuge to obtain the supernatant, freeze at -18°C for 22 hours, and thaw for 2 hours. After repeated freezing and thawing 3 times, centrifuge to take the solids for later use...

Embodiment 2

[0049] (1) Cold-pressed juice: select mulberries with a suitable sugar-acid ratio (sugar-acid ratio 20-30) for processing, use a concentration of 0.01g / kg stable chlorine dioxide to clean the fruit, drain after cleaning, and use a beater Crushing and beating, adding 0.5% pectinase for enzymatic hydrolysis for 30 minutes, filtering for later use;

[0050] (2) Fermented milk: select high-quality milk (protein content > 3.5g / L) for fermentation, use Streptococcus thermophilus: Lactobacillus bulgaricus: Bifidobacterium to ferment at a ratio of 1:1:1, and the addition amount is 10 5 cfu / g is fermented at 38-42°C until the pH reaches 4.5, and the fermentation is stopped for later use;

[0051] (3) Oat processing: crush the oats and pass through a 40-mesh sieve, add 15 times the mass of water, heat at 100°C for 90 minutes, use a three-legged centrifuge to obtain the supernatant, freeze at -18°C for 22 hours, and thaw for 2 hours. After repeated freezing and thawing for 5 times, cent...

Embodiment 3

[0057] (1) Cold-pressed juice: select blackberries (2-4) with suitable sugar-acid ratio for processing, and use a concentration of 0.005g / kg stable chlorine dioxide to clean the fruit, drain after cleaning, and use a beater to crush and beat the juice. Add 1% pectinase for enzymatic hydrolysis for 60 minutes, filter and set aside;

[0058] (2) Fermented milk: select high-quality milk (protein content > 3.5g / L) for fermentation, use Streptococcus thermophilus: Lactobacillus bulgaricus: Bifidobacterium to ferment at a ratio of 1:1:1, and the addition amount is 10 5 cfu / g was fermented at 38-42°C until the pH reached 4.2, and the fermentation was stopped for later use;

[0059] (3) Oat processing: crush the oats and pass through a 40-mesh sieve, add 12 times the mass of water, heat at 100°C for 60 minutes, use a three-legged centrifuge to obtain the supernatant, freeze at -18°C for 22 hours, and thaw for 2 hours. After repeated freezing and thawing 4 times, centrifuge to take th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com