Novel and intelligent dedicated equipment of thermal spraying wear-resistant workpiece

A special equipment and thermal spraying technology, applied in the direction of spraying devices, liquid spraying devices, etc., can solve the problems of inaccurate control of coating thickness, environmental pollution of manual operation, and wear resistance of workpieces, and achieve shortened debugging time and accurate trajectory , Improve the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

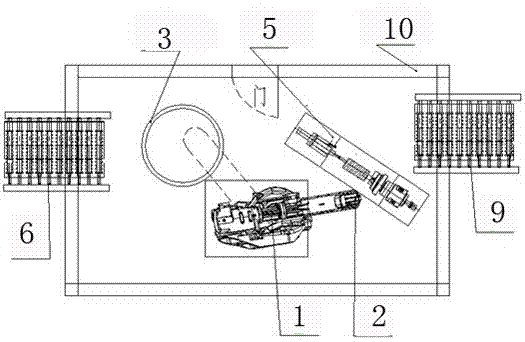

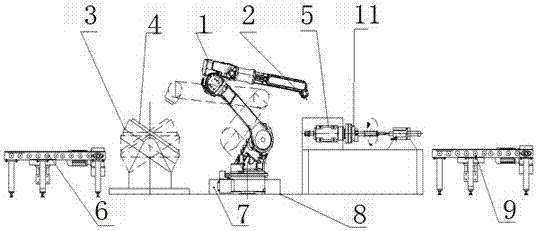

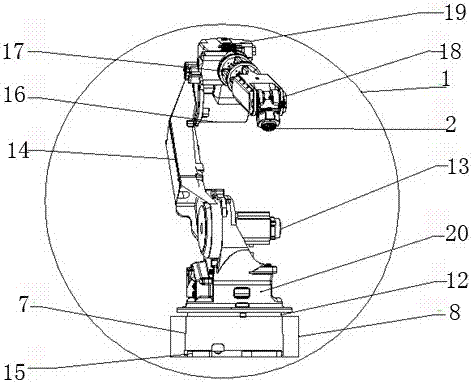

[0019] In order to better understand and implement, the present invention will be further described below in conjunction with the accompanying drawings: the special equipment for novel intelligent thermal spraying wear-resistant workpieces includes intelligent six-axis robot 1 and PLC automatic control system, and the left front of intelligent six-axis robot 1 is set There is a turntable fixture tooling 3, a turntable fixture tooling 5 is installed in the front right, a preheating crawler transmission device 6 is installed on the left side of the turntable fixture tooling 3, a cooling crawler belt transmission device 9 is installed on the right side of the turntable fixture tooling 5, and a turntable fixture tooling 3 Pneumatic clamp 4 is provided on the top, pneumatic clamp 11 is provided on the turntable fixture tooling 5, spray gun 2 is provided on the intelligent six-axis robot 1, alloy powder storage barrel 7 is provided under the intelligent six-axis robot 1, the alloy pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com