Appearance-controllable indium oxide powder and low-temperature hydrothermal synthesis method thereof

A hydrothermal synthesis and indium oxide technology, applied in chemical instruments and methods, gallium/indium/thallium compounds, inorganic chemistry, etc., can solve the problems of difficult distribution control, material structure easy to collapse, and limited effective sites of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

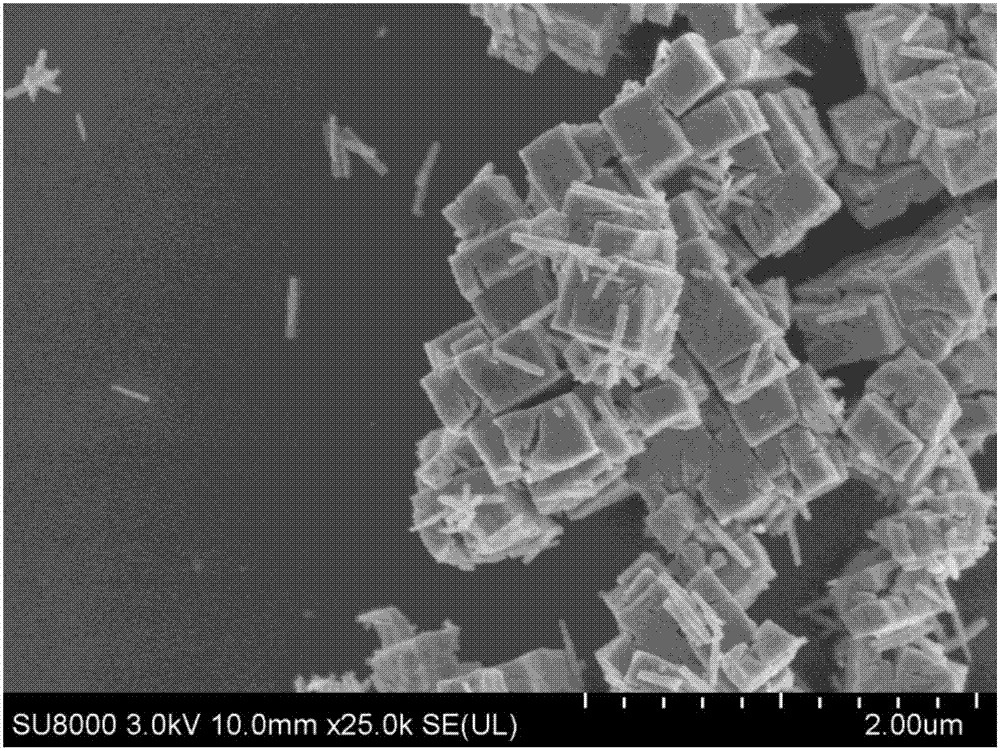

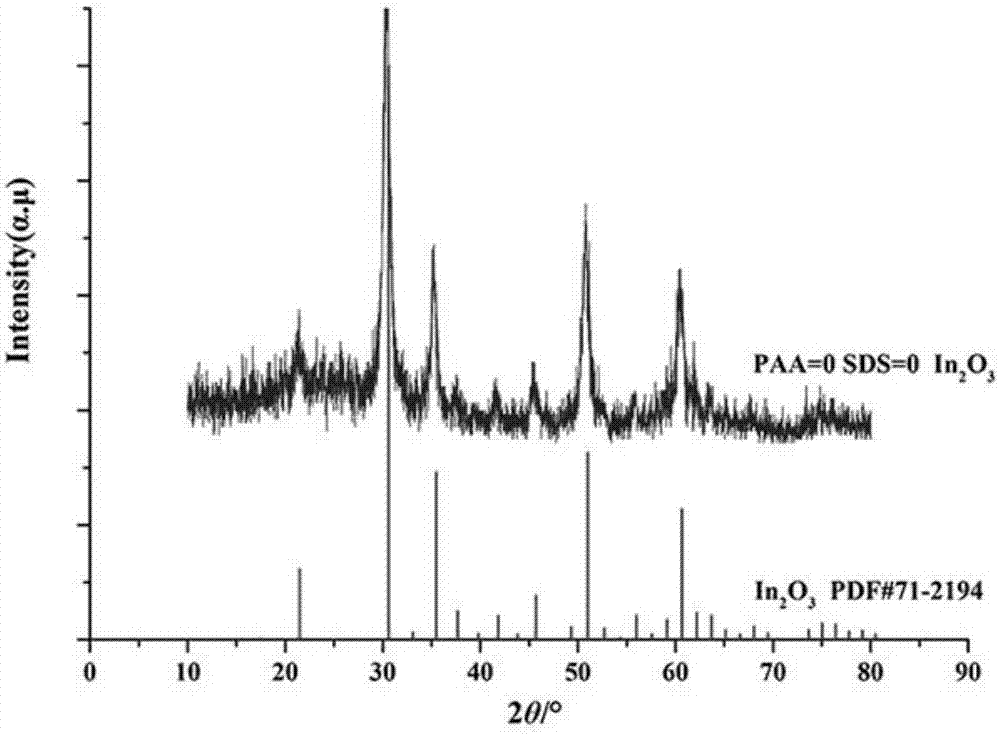

Embodiment 1

[0068] (1) Preparation of indium source prepolymer solution

[0069] 3.06g of In(NO 3 ) 3 4.5H 2 O was dissolved in distilled water and adjusted to 100 mL to obtain a 0.08 mol / L indium source aqueous solution. Take 25mL of 0.08mol / L indium source aqueous solution, add 25mL of distilled water, and then add + Nitric acid aqueous solution with a concentration of 2.0 mol / L was used to adjust the pH value of the solution to =1, and magnetically stirred at 80° C. for 30 minutes to obtain an indium source prepolymer solution A.

[0070] (2) Preparation of alkali source prepolymer solution

[0071] Dissolve 1.8g of urea granules in distilled water to a volume of 50mL, add + Aqueous nitric acid solution with a concentration of 2.0 mol / L was used to adjust the pH of the solution to 1, and magnetically stirred at 80° C. for 30 minutes to obtain alkali source prepolymer solution B.

[0072] (3) Preparation of indium hydroxide precursor

[0073] Mix the indium source prepolymer solu...

Embodiment 2

[0077] (1) Preparation of indium source prepolymer solution

[0078] Take 1.33g of PAA original solution (mass fraction 30%) and dissolve it in distilled water to make up to 1L, and prepare PAA aqueous solution 1 with a concentration of 0.4g / L. 3.06g of In(NO 3 ) 3 4.5H 2 O was dissolved in distilled water to 100 mL to obtain 0.08 mol / L indium source aqueous solution 2. Take 25mL of 0.08mol / L indium source aqueous solution and add it to 25mL PAA aqueous solution 1, add + Nitric acid aqueous solution with a concentration of 2.0 mol / L was used to adjust the pH value of the solution to =1, and magnetically stirred at 80° C. for 30 minutes to obtain an indium source prepolymer solution A.

[0079] (2) Preparation of alkali source prepolymer solution

[0080]1.33 g of the PAA original solution (30% by mass) was dissolved in distilled water to make up to 1 L, and PAA aqueous solution 3 with a concentration of 0.4 g / L was prepared. Dissolve 1.1 g of SDS in distilled water and m...

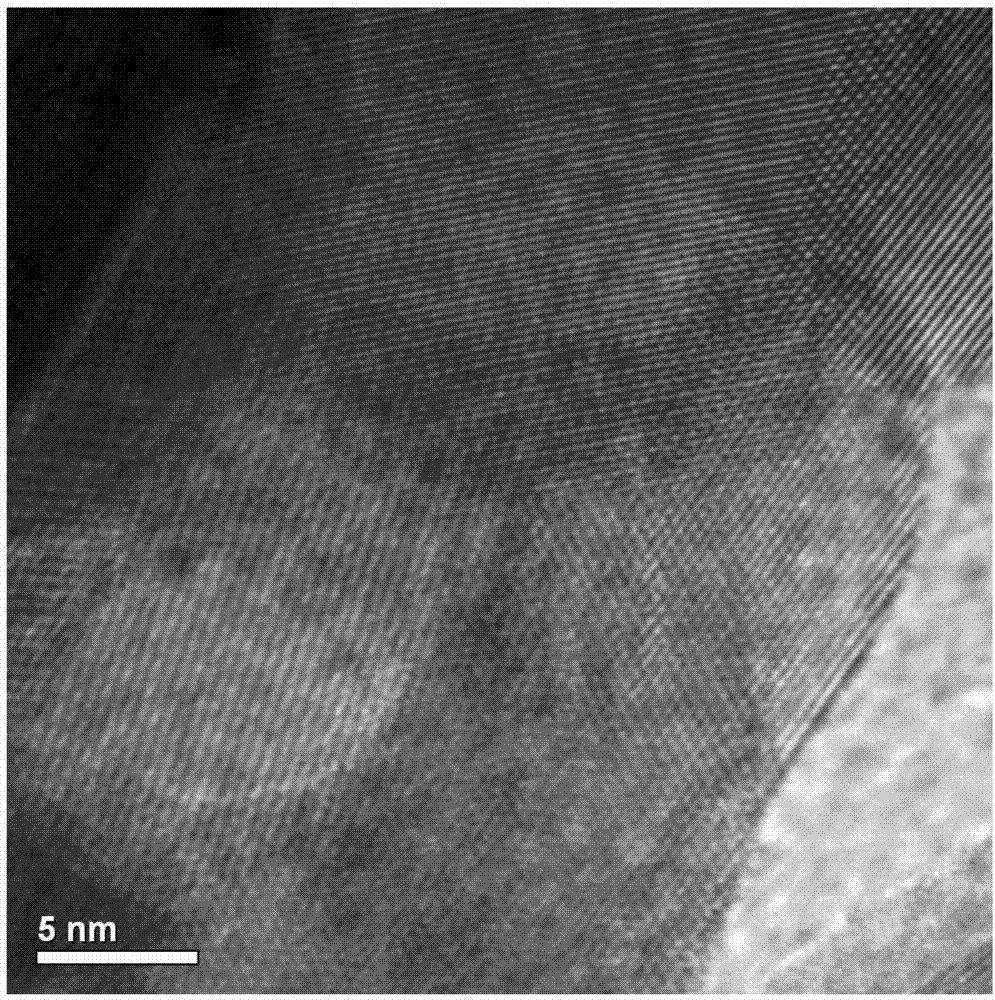

Embodiment 3

[0086] (1) Preparation of indium source prepolymer solution

[0087] Take 3.33 g of PAA original solution (mass fraction 30%), add distilled water to make up to 1 L, and prepare water PAA solution 1 with a concentration of 1.0 g / L. 3.06g of In(NO 3 ) 3 4.5H 2 O was dissolved in distilled water to 100 mL to obtain 0.08 mol / L indium source aqueous solution 2. Add 25mL indium source aqueous solution 2 into the 25mL PAA aqueous solution 1, add H + Nitric acid aqueous solution with a concentration of 2.0 mol / L was used to adjust the pH value of the solution to =1, and magnetically stirred at 80° C. for 30 minutes to obtain an indium source prepolymer solution A.

[0088] (2) Preparation of alkali source prepolymer solution

[0089] Take 3.33 g of PAA original solution (mass fraction 30%), add distilled water to make up to 1 L, and prepare PAA aqueous solution 3 with a concentration of 1.0 g / L. Dissolve 1.1 g of SDS in distilled water and make up to 1 L to prepare water SDS so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com