Method of using nitrogen-doped titanium dioxide to enhance algae coagulation while degrading algae-containing sediment under visible light

A sediment and algae technology, applied in chemical instruments and methods, sludge treatment, water/sludge/sewage treatment, etc., can solve problems such as increasing the burden of the treatment process, reducing the algae removal efficiency, affecting human health, etc., to avoid problems such as Heavy metal pollution, small environmental impact, and the effect of reducing the content of heavy metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

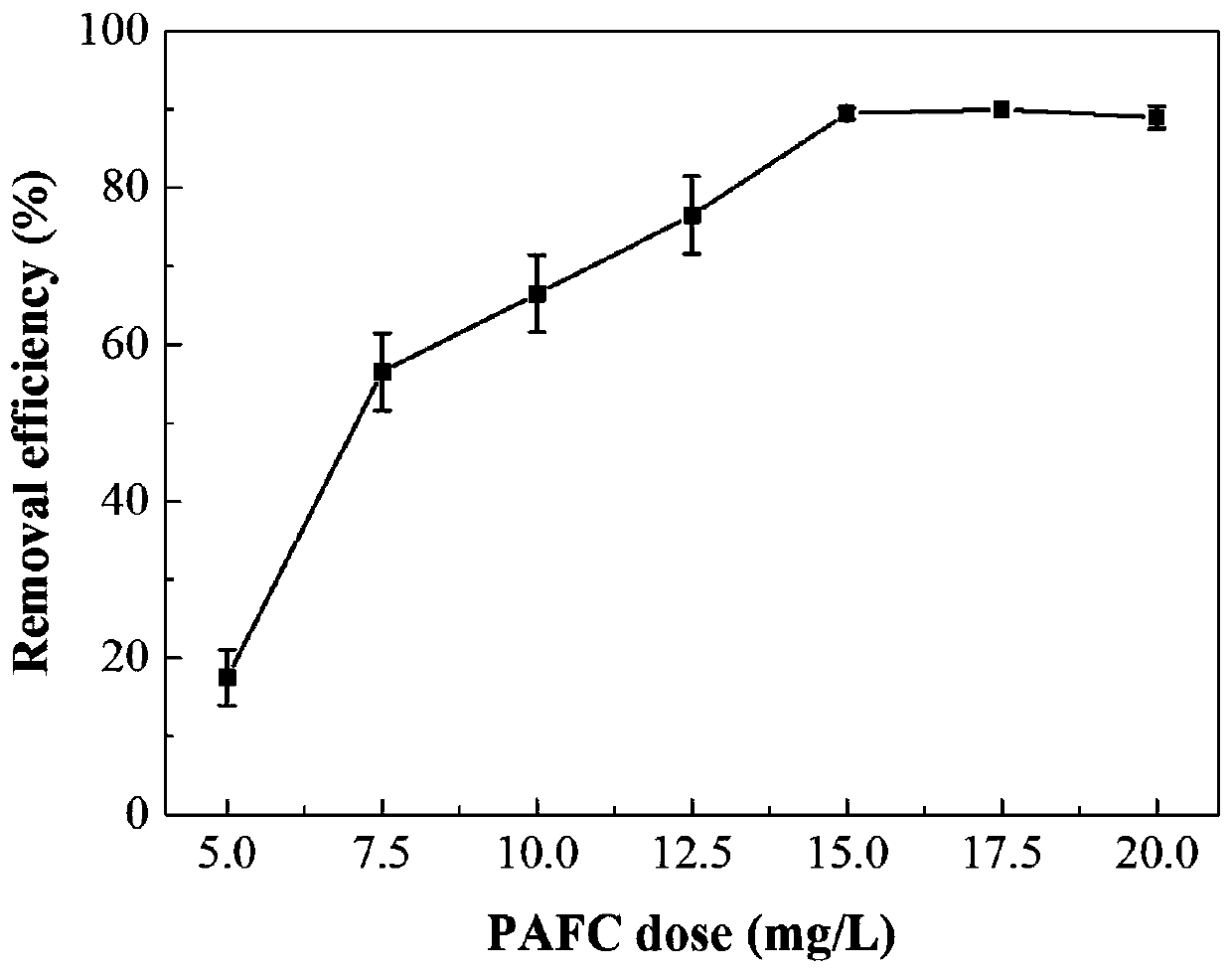

[0052] The algae-removing coagulant consists of the following components by weight: 50 parts by weight of N-TiO 2 powder (particle size 100 mesh) and 7.5 parts by weight of polyaluminum ferric chloride.

[0053] The Microcystis aeruginosa (Microcystisaeruginosa) used in the experiment was cultured in BG11 medium at a temperature of 25°C, 12 hours of light, 12 hours of darkness, and a light intensity of 2000 lux. It was cultivated to the logarithmic growth stage and used to prepare water sources containing algae for experiments.

[0054] Dilute the algae solution to 1×10 with deionized water 6 cells / mL, prepared as an experimental water source, the volume of the treated water sample is 1L, and the N-TiO 2 Mix 50 mg of powder and 7.5 mg of polyaluminum ferric chloride into each liter of experimental water source, stir at 250 rpm for 1 min, and stir at 30 rpm for 30 min to complete the coagulation process. During the coagulation process and within 2 hours after the completion o...

Embodiment 2

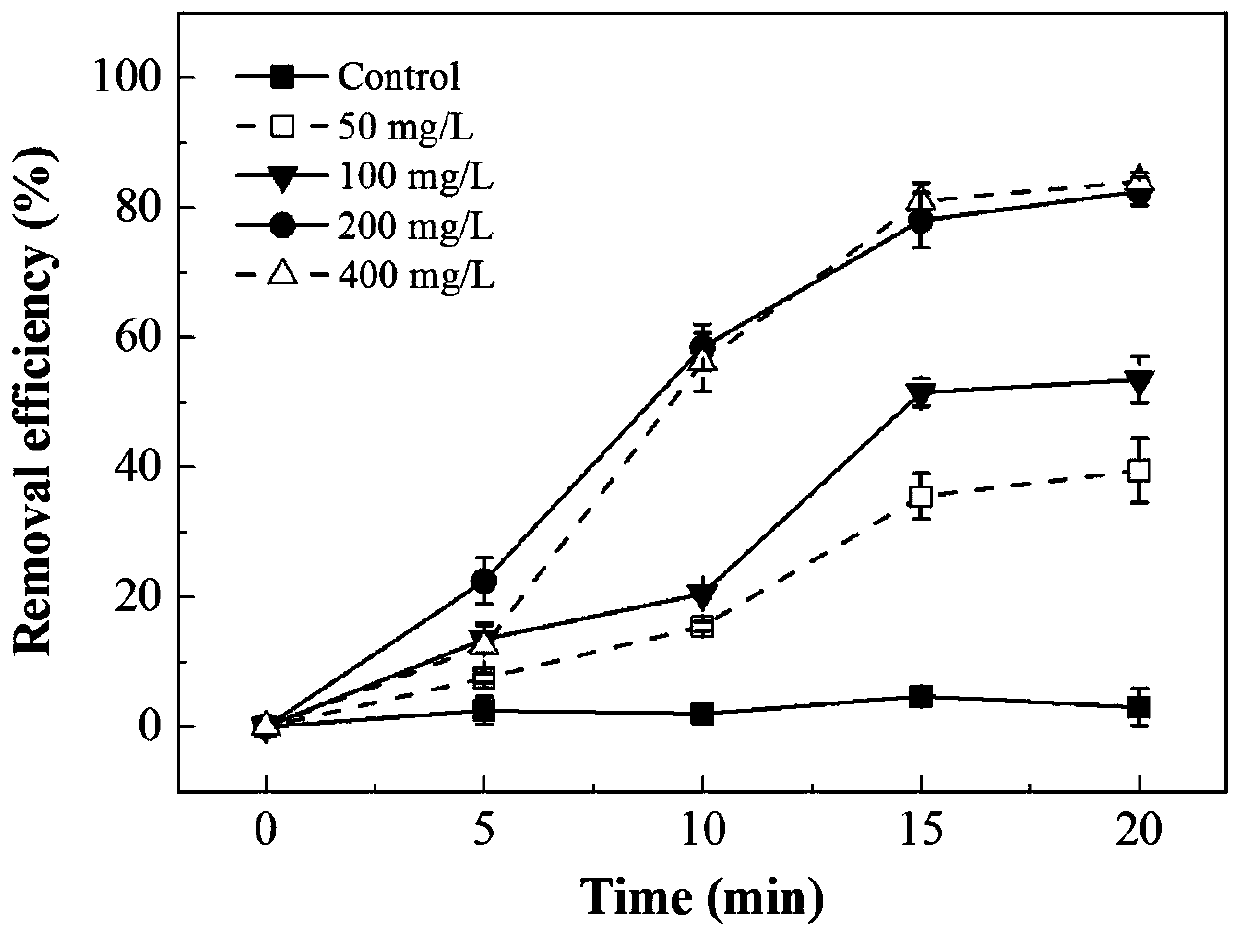

[0057] The algae-removing coagulant is composed of the following components by weight: 100 parts by weight of N-TiO 2 powder (particle size 100 mesh) and 7.5 parts by weight of polyaluminum ferric chloride.

[0058] The Microcystis aeruginosa (Microcystisaeruginosa) used in the experiment was cultured in BG11 medium at a temperature of 25°C, 12 hours of light, 12 hours of darkness, and a light intensity of 2000 lux. It was cultivated to the logarithmic growth stage and used to prepare water sources containing algae for experiments.

[0059] Dilute the algae solution to 1×10 with deionized water 6 cells / mL, prepared as an experimental water source, the volume of the treated water sample is 1L, and the N-TiO 2 Mix 100mg of powder and 7.5mg of polyaluminum ferric chloride into each liter of experimental water source, stir at 250rpm for 1min, and stir at 30rpm for 30min to complete the coagulation process. During the coagulation process and within 2 hours after the completion of...

Embodiment 3

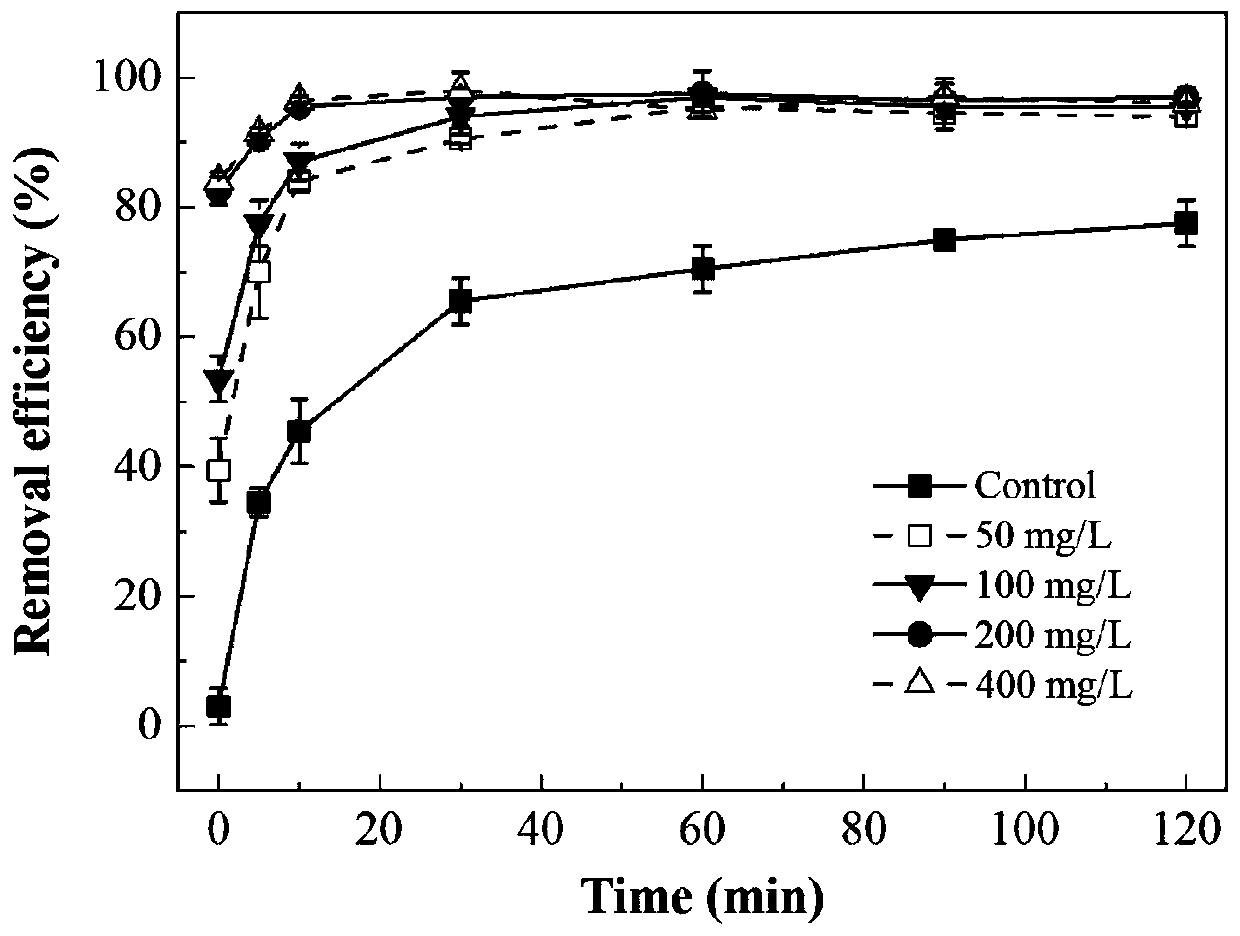

[0062] The algae-removing coagulant consists of the following components by weight: 200 parts by weight of N-TiO 2 powder (particle size 100 mesh) and 7.5 parts by weight of polyaluminum ferric chloride.

[0063] The Microcystis aeruginosa (Microcystisaeruginosa) used in the experiment was cultured in BG11 medium at a temperature of 25°C, 12 hours of light, 12 hours of darkness, and a light intensity of 2000 lux. It was cultivated to the logarithmic growth stage and used to prepare water sources containing algae for experiments.

[0064] Dilute the algae solution to 1×10 with deionized water 6 cells / mL, prepared as an experimental water source, the volume of the treated water sample is 1L, and the N-TiO 2 Mix 200mg of powder and 7.5mg of polyaluminum ferric chloride into each liter of experimental water source, stir at 250rpm for 1min, and stir at 30rpm for 30min to complete the coagulation process. During the coagulation process and within 2 hours after the completion of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com