Permanent magnetic ferrite sintered magnet injection moulding granule material and preparation method and application thereof

A technology of permanent ferrite and sintered magnets, applied in the direction of inductance/transformer/magnet manufacturing, magnetic materials, magnetic objects, etc., to achieve low viscosity, improve dispersion uniformity, and improve the effect of bending deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The components and volume fractions of the pellets are as follows:

[0030]

[0031] Wherein: the volume fraction of each component of the modified wax matrix is as follows:

[0032] Carnauba Wax 70%

[0034] Microcrystalline Wax 5%

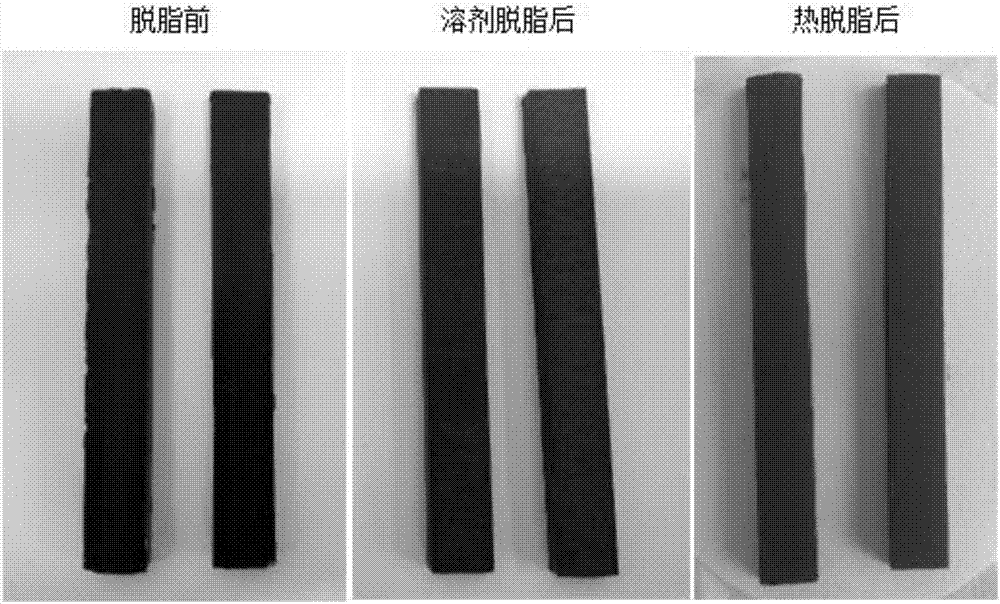

[0035] According to the above formula, mix carnauba wax (8015-86-9), polyamide wax (NEW-0404) and microcrystalline wax (No. 80) at 100°C to obtain modified wax matrix particles; High-density polyethylene (8050), modified wax matrix, stearic acid (57-11-4) and strontium ferrite powder are mixed evenly, and then extruded and granulated in a twin-screw extruder to obtain mixed feed. The rotational speed is 20rad / s, the rotational speed of the feeder is 16rad / s, and the temperature of the extruder is 130, 130, 135, 140, 140°C from the feed port to the discharge port. Injection-molding the prepared pellets on an injection-molding machine to obtain an injection-molded green body of a sintered magnet. The inje...

Embodiment 2

[0037] The components and volume fractions of the pellets are as follows:

[0038]

[0039]

[0040] Wherein: the volume fraction of each component of the modified wax matrix is as follows:

[0041] Carnauba Wax 70%

[0043] Microcrystalline Wax 5%

[0044]According to the above formula, mix carnauba wax (8015-86-9), polyamide wax (NEW-0404) and microcrystalline wax (No. 80) at 100°C to obtain modified wax matrix particles; High-density polyethylene (8050), modified wax matrix, stearic acid (57-11-4) and strontium ferrite powder are mixed evenly, and then extruded and granulated in a twin-screw extruder to obtain mixed feed. The rotational speed is 20rad / s, the rotational speed of the feeder is 16rad / s, and the temperature of the extruder is 130, 130, 135, 140, 140°C from the feed port to the discharge port. Injection-molding the prepared pellets on an injection-molding machine to obtain an injection-molded green body of a sintered magnet...

Embodiment 3

[0046] The components and volume fractions of the pellets are as follows:

[0047]

[0048] Wherein: the volume fraction of each component of the modified wax matrix is as follows:

[0049] Carnauba Wax 70%

[0050] Polyamide Wax 25%

[0051] Microcrystalline Wax 5%

[0052] According to the above formula, mix carnauba wax (8015-86-9), polyamide wax (NEW-0404) and microcrystalline wax (No. 80) at 100°C to obtain modified wax matrix particles; High-density polyethylene (8050), modified wax matrix, stearic acid (57-11-4) and strontium ferrite powder are mixed evenly, and then extruded and granulated in a twin-screw extruder to obtain mixed feed. The rotational speed is 20rad / s, the rotational speed of the feeder is 16rad / s, and the temperature of the extruder is 130, 130, 135, 140, 140°C from the feed port to the discharge port. Injection-molding the prepared pellets on an injection-molding machine to obtain an injection-molded green body of a sintered magnet. The inje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com