Carbamate mercaptan epoxy curing agent as well as preparation method and application thereof

A urethane-based, epoxy curing agent technology, applied in the direction of epoxy resin glue, epoxy resin coating, adhesives, etc., can solve the problems of coating film disadvantages, long curing process, affecting workers' health, etc., to improve flexibility Sexuality and mechanical properties, improve flexibility and impact resistance, and shorten curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

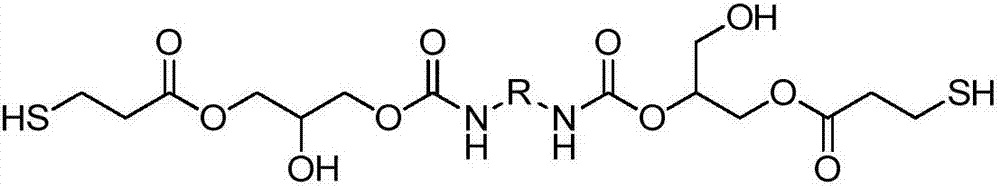

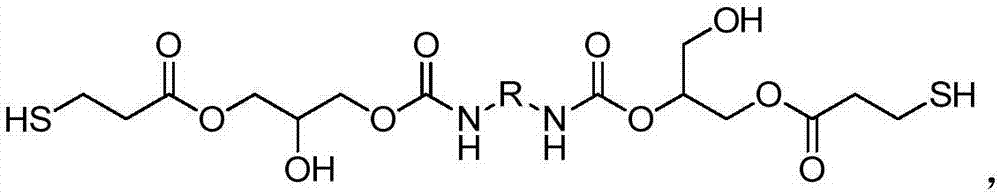

[0020] Preparation of mercapto-containing cyclic carbonate: 11.8 parts of glycerol carbonate, 15.9 parts of 3-mercaptopropionic acid, 1.4 parts of p-toluenesulfonic acid, and 2.1 parts of anhydrous magnesium sulfate were added to the reaction flask. React at 80°C for 8 hours, wash and dry to obtain mercapto-containing cyclocarbonate.

[0021] Take 8.2 parts of mercapto-containing cyclocarbonate, 1.2 parts of ethylenediamine, and 0.47 parts of benzyl alcohol, mix them, heat and react in a water bath at 60°C for 2 hours, and obtain an ethylenediaminocarbamate thiol curing agent.

[0022] Take 4.2 parts of curing agent, mix with 0.51 parts of ethylenediamine, 0.04 parts of triethylamine, 9.8 parts of E44 epoxy resin, and 0.98 parts of butyl glycidyl ether, and scrape the film on the tin plate for testing the mechanical properties. Pour onto Teflon plates to test open time.

Embodiment 2

[0026] Take 8.2 parts of mercapto-containing cyclic carbonates in Example 1, 3.4 parts of isophorone diamine, and 0.58 parts of benzyl alcohol, and then heat and react in a water bath at 60°C for 2 hours to obtain isophorone diamine carbamate sulfur Alcohol curing agent.

[0027] Take 3.0 parts of curing agent, mix with 0.84 parts of isophorone diamine, 0.04 parts of triethylamine, 5.7 parts of E44 epoxy resin, and 0.57 parts of butyl glycidyl ether, and scrape the film on the tin plate for testing the mechanical properties , and the remaining material was poured on a polytetrafluoroethylene plate to test the opening time.

Embodiment 3

[0031] Take 8.2 parts of mercapto-containing cyclic carbonates in Example 1, 2.7 parts of m-xylylenediamine, and 0.55 parts of benzyl alcohol and mix them and heat them in a water bath at 60°C for 4 hours to obtain m-xylylenediamine carbamate thiols Hardener.

[0032] Take 4.2 parts of curing agent, mix with 0.04 part of triethylamine, part of E44 epoxy resin, and part of butyl glycidyl ether, scrape the film on the tinplate plate to test the mechanical properties, and pour the rest on the polytetrafluoroethylene plate Test opening hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com