Recovery utilization method of plastics

A technology for plastics and mixed materials, applied in the field of plastic products, can solve the problems of affecting the sustainable use of land, low density of plastic waste, increasing pressure on land resources, etc., to reduce losses, speed up paint stripping, and improve utilization efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

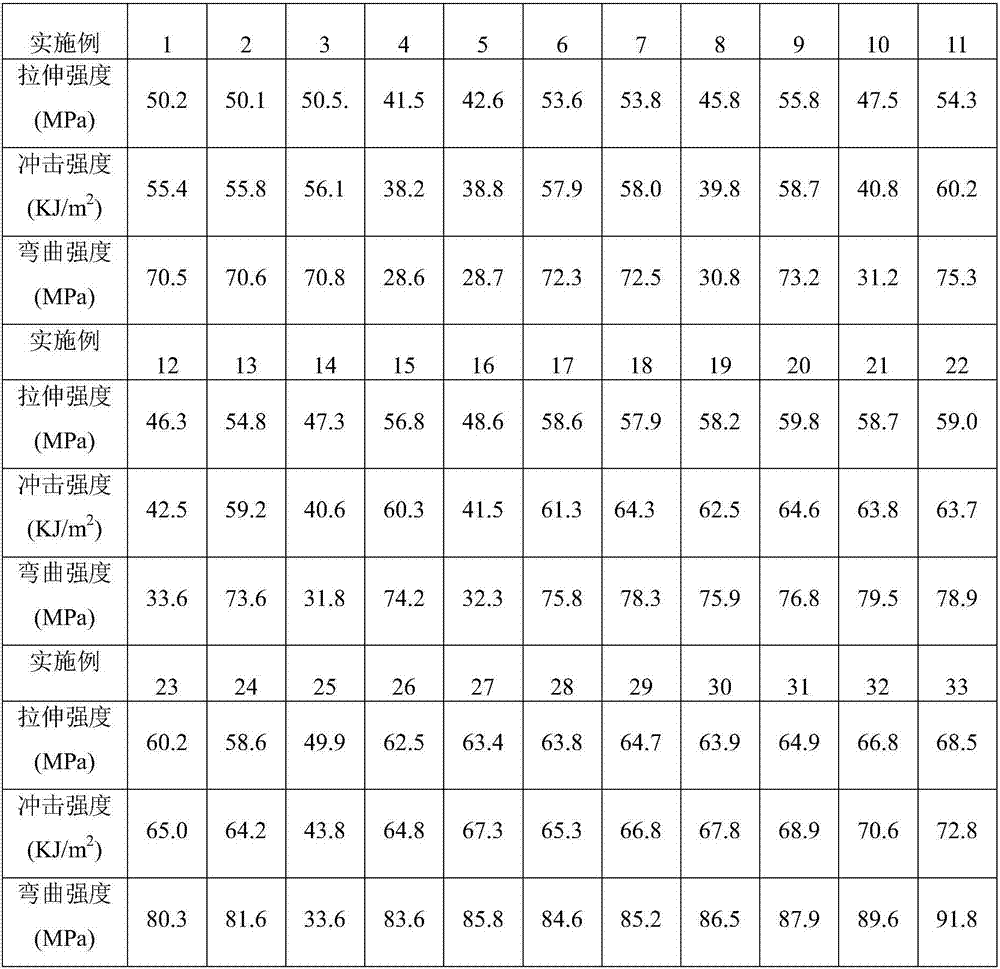

Examples

Embodiment 1

[0029] A method for recycling plastics, comprising the steps of:

[0030] Step 1. After crushing the recovered plastic, add it to the cleaning solution for ultrasonic cleaning, stir and clean it with water, dry it, then add it to the paint remover solution and soak it ultrasonically for 60 minutes, stir it with water, and dry it to obtain the pretreated plastic;

[0031] Step 2, by weight, take 100 parts of pretreated plastics, 10 parts of toughening agent, 1 part of accelerator, 10 parts of modified montmorillonite powder, 3 parts of anti-aging agent, 3 parts of light stabilizer and add them to the high-speed mixer to The rotating speed of 15000rpm was stirred and mixed for 5min to obtain the mixture;

[0032]Step 2. Add the obtained mixture into an integrated ultrasonic extrusion device, and extrude and granulate under the action of ultrasonic power 500W and frequency 30KHz to manufacture molded products; the screw speed of the integrated ultrasonic extrusion device is 50r ...

Embodiment 2

[0035] A method for recycling plastics, comprising the steps of:

[0036] Step 1. After crushing the recovered plastic, add it to the cleaning solution for ultrasonic cleaning, stir and clean it with water, dry it, then add it into the paint remover solution and soak it ultrasonically for 120 minutes, stir it with water, and dry it to obtain the pretreated plastic;

[0037] Step 2, by weight, get 120 parts of pretreated plastics, 20 parts of toughening agent, 3 parts of accelerator, 15 parts of modified montmorillonite powder, 5 parts of antiaging agent, 5 parts of light stabilizer and add in high-speed mixer, with The rotating speed of 25000rpm was stirred and mixed for 5min to obtain the mixture;

[0038] Step 2. Add the obtained mixture into an ultrasonic extrusion integrated device, and extrude and granulate under the action of ultrasonic power of 1000W and frequency of 50KHz to manufacture molded products; the screw speed of the ultrasonic extrusion integrated device is 1...

Embodiment 3

[0041] A method for recycling plastics, comprising the steps of:

[0042] Step 1. After crushing the recovered plastic, add it to the cleaning solution for ultrasonic cleaning, stir and clean it with water, and dry it, then add it to the paint remover solution and soak it ultrasonically for 90 minutes, stir it with water, and dry it to obtain the pretreated plastic;

[0043] Step 2, by weight, get 110 parts of pretreated plastics, 15 parts of toughening agent, 2 parts of accelerator, 12 parts of modified montmorillonite powder, 4 parts of antiaging agent, 4 parts of light stabilizer and add in high-speed mixer, with The rotating speed of 20000rpm was stirred and mixed for 8min to obtain the mixture;

[0044] Step 2. Add the obtained mixture into an ultrasonic extrusion integrated device, and extrude and granulate under the action of ultrasonic power 800W and frequency 40KHz to manufacture molded products; the screw speed of the ultrasonic extrusion integrated device is 80r / m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com