Method of simultaneous saccharification total fermentation

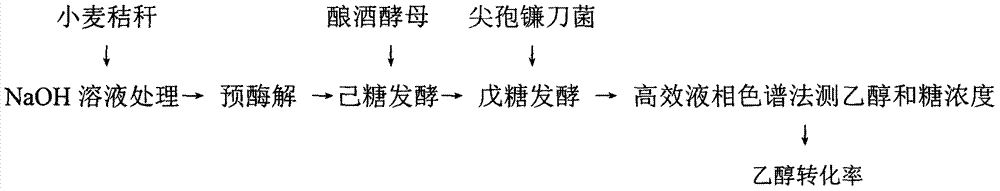

A simultaneous saccharification fermentation and simultaneous saccharification technology, applied in fermentation, biochemical equipment and methods, and microbial-based methods, can solve the problems of low xylose utilization, high production costs of in situ enzymes, and low lignocellulose conversion efficiency. problems, to achieve the effect of improving conversion efficiency, improving utilization rate, and high alcohol concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Cut the naturally air-dried wheat straw into small pieces with a length of less than 3cm, add 0.5mol / L NaOH solution according to the ratio of material to liquid 1:20 (g:mL), mix well, and place in a high-pressure steam sterilizer at 121°C 1. Pretreatment for 1 hour, washing the solid residue with water until neutral, drying and pulverizing.

[0020] (2) Pre-enzymolyze the above-mentioned material treated with NaOH, the reaction volume is 100 mL, and the dextran loading is 3% (w / v). Pre-enzymatic hydrolysis for 12-24 hours. Cellulase and β-glucosidase were added to the enzymatic hydrolysis system at an enzyme load of 25 FPU / g dextran, and xylanase was added to the enzyme system at a load of 10 mg / g dextran. Ampickanamycin with a final concentration of 50 mg / L was added to prevent bacterial contamination during the fermentation process.

[0021] (3) The enzymatic hydrolysis condition is 50°C, the rotating speed of the shaker is 180 rpm, and 1 mL is taken after 12 h...

Embodiment 2

[0025] (1) Cut the naturally air-dried wheat straw into small pieces with a length of less than 3cm, add 0.5mol / L NaOH solution according to the ratio of material to liquid 1:20 (g:mL), mix well, and place in a high-pressure steam sterilizer at 121°C 1. Pretreatment for 1 hour, washing the solid residue with water until neutral, drying and pulverizing.

[0026] (2) Pre-enzymolyze the above-mentioned material treated with NaOH, the reaction volume is 100 mL, and the dextran loading is 3% (w / v). Pre-enzymatic hydrolysis for 12-24 hours. Cellulase and β-glucosidase were added to the enzymatic hydrolysis system at an enzyme load of 25 FPU / g dextran, and xylanase was added to the enzyme system at a load of 10 mg / g dextran. Ampickanamycin with a final concentration of 50 mg / L was added to prevent bacterial contamination during the fermentation process.

[0027] (3) The enzymatic hydrolysis condition is 50°C, the rotating speed of the shaker is 180 rpm, and 1 mL is taken after 12 h...

Embodiment 3

[0031] (1) Cut the naturally air-dried wheat straw into small pieces with a length of less than 3cm, add 0.5mol / L NaOH solution according to the ratio of material to liquid 1:20 (g:mL), mix well, and place in a high-pressure steam sterilizer at 121°C 1. Pretreatment for 1 hour, washing the solid residue with water until neutral, drying and pulverizing.

[0032] (2) Pre-enzymolyze the above-mentioned material treated with NaOH, the reaction volume is 100 mL, and the dextran loading is 3% (w / v). Pre-enzymatic hydrolysis for 12-24 hours. Cellulase and β-glucosidase were added to the enzymatic hydrolysis system at an enzyme load of 25 FPU / g dextran, and xylanase was added to the enzyme system at a load of 10 mg / g dextran. Ampickanamycin with a final concentration of 50 mg / L was added to prevent bacterial contamination during the fermentation process.

[0033] (3) The enzymatic hydrolysis condition is 50°C, the rotating speed of the shaker is 180pm, and 1 mL is taken after 12 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com